Time:2025-08-13

Colored Silicone Neon Strip stands as a versatile lighting solution that marries vivid, consistent color with the durability of silicone construction. These strips have become a go-to choice for designers and homeowners seeking to infuse spaces with personality, as they offer a spectrum of bold and subtle hues in a form that withstands the rigors of both indoor and outdoor use. Unlike traditional colored neon tubes, which are fragile and limited in flexibility, or basic colored LED strips lacking protective casings, Colored Silicone Neon Strip delivers long-lasting, weather-resistant color that adapts to diverse environments. From accentuating architectural features to creating thematic atmospheres, these strips bridge the gap between aesthetic appeal and practical performance. This article explores their color formulation, material engineering, application diversity, installation best practices, and maintenance tips, highlighting how they redefine colored lighting in modern design.

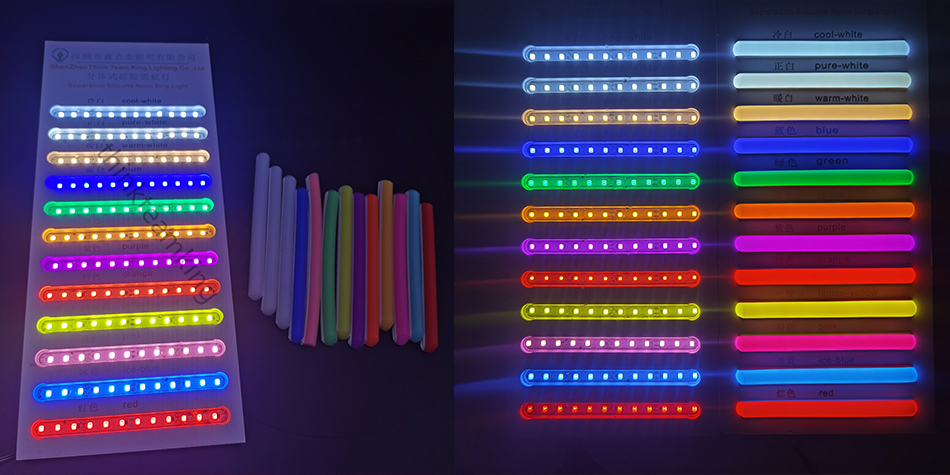

The striking colors of Colored Silicone Neon Strip are the result of careful formulation and engineering, ensuring vibrancy and uniformity across each strip. Premixed LED technology is at the core, with LEDs manufactured to emit specific, saturated colors rather than relying on filters or coatings that can fade over time. This includes classic options like deep red, royal blue, emerald green, and warm amber, as well as more nuanced shades such as lavender, teal, and coral. Each LED is calibrated to ensure consistent color output, so even across multiple strips, the hue remains uniform—critical for large installations like signage or building exteriors.

Color stability is a key advantage, with high-quality strips retaining their vibrancy over extended periods. Unlike some colored lighting solutions that dull or shift tint due to UV exposure or heat, Colored Silicone Neon Strip uses LEDs with encapsulants that resist color degradation. The silicone casing further protects against UV rays, ensuring that outdoor strips installed in direct sunlight maintain their original hue for years. This stability makes them ideal for branding applications, where consistent color is essential for reinforcing visual identity.

Light diffusion through the silicone casing enhances color quality by softening the output of individual LEDs. This creates a smooth, even glow that eliminates hotspots or pixelation, allowing the color to appear continuous across the strip’s length. Whether viewed up close or from a distance, the color remains consistent, making the strips suitable for both detailed accent lighting and large-scale installations. The diffusion also reduces glare, ensuring that even bold colors like bright red or electric blue don’t feel harsh in living spaces.

Opacity control in the silicone casing allows for customization of color intensity. Some strips feature a slightly opaque casing that deepens the color, creating a richer, more dramatic effect, while others use a clearer silicone to maximize brightness without compromising hue. This versatility lets users choose between subtle ambient color and eye-catching, high-impact lighting, depending on the application.

The silicone casing of Colored Silicone Neon Strip is engineered to safeguard both the color integrity and the structural durability of the strip. Weather resistance is a standout feature, with the silicone forming a waterproof barrier that protects internal LEDs from rain, snow, humidity, and dust. This makes the strips suitable for outdoor use—from garden pathways to building facades—without 担心 water damage affecting color output. Unlike PVC-cased strips, which can crack in extreme temperatures, silicone remains flexible in cold conditions and stable in heat, ensuring the color doesn’t distort or fade due to environmental stress.

Impact resistance ensures the strips hold up in high-traffic areas. The silicone acts as a shock absorber, protecting the LEDs from bumps, drops, and minor impacts that could otherwise damage the light source or disrupt color consistency. This durability makes them ideal for commercial spaces like retail stores, restaurants, and event venues, where lighting may be exposed to frequent activity or handling.

Chemical and UV resistance prevents color degradation from external factors. The silicone is formulated to resist damage from common chemicals such as cleaning agents, oils, and pollutants, which can cause discoloration in lesser materials. Additionally, UV inhibitors in the silicone prevent the casing itself from yellowing over time—a common issue with clear plastics—ensuring that the color of the light isn’t distorted by a tinted casing.

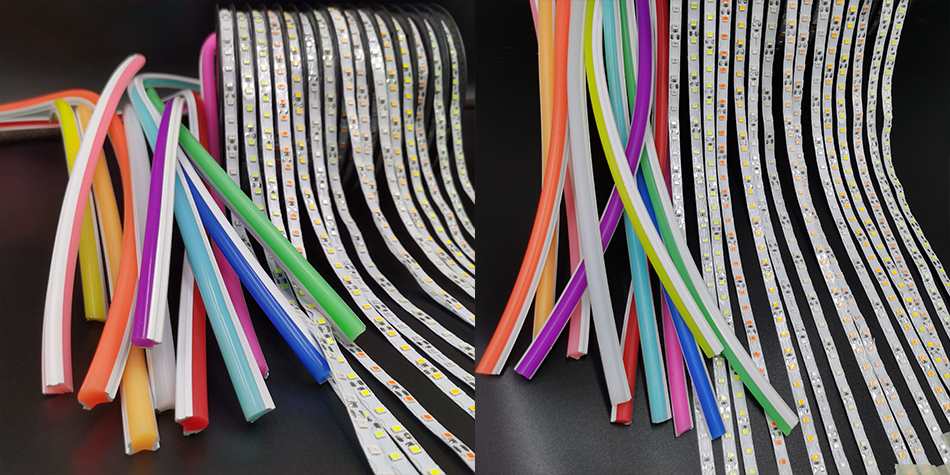

Flexibility without compromise allows the strips to maintain color uniformity even when bent or shaped. The silicone casing and underlying circuit board are designed to bend around corners, wrap around objects, or form curves without putting stress on the LEDs, which could alter their color output. This flexibility expands installation possibilities, enabling colored lighting in spaces with irregular shapes, such as curved walls, furniture edges, or decorative sculptures.

Colored Silicone Neon Strip’s combination of vibrant color and durability makes it suitable for a wide range of applications, adding personality and purpose to any environment. Residential design leverages these strips to create custom atmospheres. In living rooms, a deep blue strip behind a media center can evoke a cinematic vibe, while a soft amber strip under kitchen cabinets adds warmth to meal preparation areas. Bedrooms use calming greens or lavenders to promote relaxation, with strips installed along headboards or ceiling edges. Outdoor patios benefit from weather-resistant red or green strips during holidays, or neutral tones like terracotta to complement landscaping.

Commercial branding relies on Colored Silicone Neon Strip to reinforce visual identity. Retail stores use brand-specific colors in window displays or along shelving to create a cohesive look, while restaurants and cafes adopt thematic hues—such as coastal blues for a seafood spot or earthy oranges for a Mexican eatery—to enhance their ambiance. Hotels integrate colored strips into lobbies, using signature colors to create memorable first impressions, or in guest rooms to offer customizable mood lighting.

Architectural accenting uses colored strips to highlight building features. Historic buildings may use warm whites or soft golds to emphasize ornate details, while modern structures employ bold blues or purples to showcase sleek lines. Bridges, monuments, and public spaces use colored strips to create iconic nighttime looks, with colors often changing to mark events or seasons—green for St. Patrick’s Day, red and green for Christmas, or pastels for spring.

Event and entertainment spaces depend on Colored Silicone Neon Strip for temporary and permanent installations. Concert venues use bright, energetic colors like magenta and cyan to amplify the mood, while wedding venues opt for soft pinks or ivories to create romantic atmospheres. Pop-up shops and trade shows use colored strips to draw attention to displays, with quick-install adhesive backing making setup and teardown efficient.

Colored Silicone Neon Strip offers distinct benefits that set it apart from other colored lighting solutions, making it a superior choice for many projects. Durability surpasses traditional colored neon, which is fragile and prone to breaking if bumped or exposed to moisture. The silicone casing of these strips protects against damage, ensuring the color remains intact even in harsh conditions. This durability reduces replacement costs and maintenance, especially in outdoor or high-traffic areas.

Color consistency outperforms colored LED strips without silicone casings, which can suffer from uneven color due to exposed LEDs or poor diffusion. The silicone casing in Colored Silicone Neon Strip ensures that the color appears smooth and uniform, even across long lengths or when viewed from different angles. This consistency is crucial for large installations where mismatched hues would undermine the design.

Weather resistance makes them more versatile than indoor-only colored lighting options. While many colored LED strips are limited to dry, indoor use, Colored Silicone Neon Strip can withstand rain, snow, and temperature fluctuations, expanding their application to outdoor spaces like gardens, patios, and building exteriors. This eliminates the need for separate indoor and outdoor colored lighting systems.

Installation flexibility exceeds rigid colored lighting fixtures, which are confined to straight lines or fixed shapes. Colored Silicone Neon Strip can be cut to custom lengths, bent around curves, or mounted on irregular surfaces, allowing for creative installations that follow the natural lines of a space. This adaptability makes them ideal for unique projects like curved signage, furniture accents, or artistic installations.

Proper installation is key to maximizing the color impact and lifespan of Colored Silicone Neon Strip. Surface preparation is essential to ensure the strip adheres securely and displays color evenly. The mounting surface should be clean, dry, and free of dust, oils, or debris—wiping with isopropyl alcohol achieves this. For porous or textured surfaces like brick or wood, mounting clips or brackets provide additional stability, preventing the strip from lifting and ensuring the color remains visible without gaps.

Cutting and connecting require precision to maintain color consistency. Most strips feature pre-marked cut lines that indicate where they can be trimmed without damaging the circuitry. Cutting outside these lines can disrupt the LED spacing, causing uneven color distribution. When connecting multiple strips, using compatible connectors ensures a seamless flow of color, with no dark spots or color shifts at the junctions. For outdoor installations, sealing connections with waterproof silicone sealant prevents moisture from affecting performance.

Orientation and placement affect how color is perceived. Installing the strip facing the desired surface—whether upward, downward, or outward—ensures the color reflects properly. For example, a blue strip mounted under a shelf should face downward to cast the color onto the floor below, while a red strip outlining a sign should face outward to maximize visibility. Avoiding direct glare by angling the strip slightly or using diffusers can enhance the color’s appearance, making it more pleasing to the eye.

Power supply matching is critical to maintaining color vibrancy. Using a power supply that matches the strip’s voltage requirements prevents underpowering (which can dull color) or overpowering (which can cause overheating and color distortion). For longer strips, adding power injectors at intervals ensures consistent voltage across the entire length, so the color remains uniform from one end to the other.

Maintaining Colored Silicone Neon Strip is straightforward, with simple steps to keep the color vibrant and the strip functioning properly. Regular cleaning removes dirt, dust, and grime that can dull the color or block light output. A soft, damp cloth is sufficient for wiping down the silicone casing—avoiding harsh chemicals or abrasive cleaners that could scratch the surface or degrade the silicone. For outdoor strips, a gentle rinse with a hose (on low pressure) can remove pollen, dirt, or debris, followed by drying with a cloth to prevent water spots.

Inspecting for damage helps catch issues before they affect color. Over time, the silicone casing may develop small tears or punctures, especially in high-traffic areas. These can be repaired with a small amount of clear silicone sealant, which seals the damage and prevents moisture from entering. If a section of the strip becomes damaged and the color fades or flickers, it can be cut off at the nearest cut line and replaced, ensuring the remaining strip continues to display consistent color.

Checking connections prevents color inconsistencies caused by loose or corroded terminals. Periodically inspecting the connections between strips and the power supply, and tightening them if necessary, ensures steady power flow—critical for maintaining uniform color. In outdoor installations, ensuring connections are properly sealed prevents corrosion, which can cause color dimming or flickering.

Protecting from extreme conditions extends the strip’s lifespan and color stability. While the silicone is resistant to temperature extremes, prolonged exposure to intense sunlight in hot climates or freezing rain in cold climates can gradually affect color over time. Providing shade or insulation in such cases can help preserve the strip’s vibrancy. Additionally, avoiding contact with sharp objects or heavy weights prevents damage to the casing that could compromise color output.

Colored Silicone Neon Strip is generally reliable, but occasional issues can be resolved with simple troubleshooting. Fading or dull color is often caused by dust buildup, a weak power supply, or exposure to extreme UV rays. Cleaning the strip, replacing the power supply with a compatible model, or moving the strip to a shaded area can restore vibrancy. In cases where UV damage is severe, replacing the affected section may be necessary.

Color inconsistency between strips may occur if strips from different batches are mixed, as slight variations in LED calibration can exist. To avoid this, purchasing strips from the same batch or manufacturer ensures uniformity. If inconsistency arises, checking and securing connections or adjusting the power supply can often resolve the issue.

Flickering or intermittent color is typically due to loose connections or a faulty power supply. Tightening connectors or replacing the power supply usually fixes this problem. For longer strips, voltage drop can cause dimming at the far end; adding a power injector midway through the strip ensures consistent power and color.

Casing discoloration (yellowing) is rare with high-quality silicone but can occur with lower-grade materials. This can distort the color of the light emitted. Preventing this by choosing strips with UV-inhibited silicone and avoiding prolonged exposure to harsh chemicals helps maintain clarity. If discoloration occurs, replacing the strip is the most effective solution.

The evolution of Colored Silicone Neon Strip continues, with emerging trends focusing on enhanced color options and sustainability. Custom color matching is becoming more accessible, allowing manufacturers to create strips in specific Pantone or brand colors for businesses seeking precise branding. This level of customization ensures that even unique or proprietary hues can be replicated in durable silicone neon form.

Eco-friendly materials are gaining traction, with manufacturers developing silicone casings made from recycled or plant-based materials without compromising color stability or durability. This aligns with growing demand for sustainable lighting solutions, reducing the environmental impact of both production and disposal.

Color-changing capabilities are being integrated into single-color strips, allowing users to switch between a few preset hues (e.g., red to green for holidays) without needing a full RGB system. This hybrid design offers versatility for users who want occasional color changes but prefer the simplicity of single-color operation.

Smart integration for colored strips is expanding, with options to control brightness and even subtle color adjustments via apps or voice assistants. This allows for dynamic color-based automation—such as dimming a blue strip in the evening or brightening a green strip during the day—enhancing both convenience and energy efficiency.

Colored Silicone Neon Strip has redefined how we use colored lighting, offering a perfect blend of vibrancy, durability, and versatility. Its ability to deliver consistent, long-lasting color in a form that adapts to indoor and outdoor environments makes it indispensable for modern design. Whether used to reinforce brand identity, create thematic atmospheres, or simply add a pop of color to a room, these strips prove that colored lighting can be both beautiful and practical.

As technology advances, their color range, sustainability, and smart capabilities will only grow, further solidifying their role in contemporary lighting design. For anyone seeking to infuse spaces with personality and resilience, Colored Silicone Neon Strip is more than a lighting choice—it’s a vibrant, enduring solution that brings color to life in every setting.