Time:2025-07-08

The Emergence and Significance of IP68-Rated Waterproof Silicone Neon Strip Lights

In an era where lighting solutions must adapt to diverse and challenging environments, IP68-rated waterproof silicone neon strip lights have emerged as a game-changing innovation. The IP68 rating, the highest in the Ingress Protection (IP) standard, signifies complete protection against dust ingress and the ability to withstand prolonged immersion in water at specific depths. When combined with the flexibility and durability of silicone material, these strip lights offer unparalleled performance in wet and harsh conditions.

From outdoor architectural lighting and poolside decorations to industrial applications and marine installations, these lights have become essential for projects where exposure to water, moisture, and dust is inevitable. They not only provide reliable illumination but also enable designers and engineers to create visually stunning effects without compromising on safety and longevity. As the demand for lighting solutions that can endure extreme environments continues to grow, IP68-rated waterproof silicone neon strip lights are leading the way in meeting these challenging requirements.

Understanding the IP68 Rating and Silicone Material

The IP68 Ingress Protection Standard

The IP rating system is a globally recognized classification that defines the degree of protection provided by an electrical enclosure against the intrusion of solid objects (such as dust) and liquids (such as water). The first digit in the IP code represents protection against solids, with 6 indicating complete protection against dust ingress. The second digit represents protection against liquids, and an 8 means the product can be continuously submerged in water under specified conditions without harmful effects.

For IP68-rated waterproof silicone neon strip lights, this means they can operate reliably in environments where they may be exposed to heavy rain, splashing water, or even complete submersion. This high level of protection ensures that the internal electrical components, including LED chips and circuit boards, remain safe and functional, significantly extending the lifespan of the lights.

The Role of Silicone Material

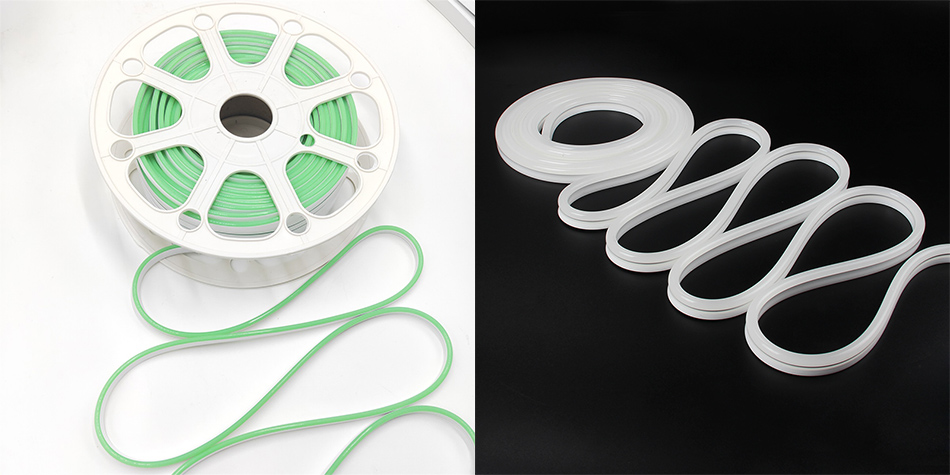

Silicone is the ideal material for housing these high-performance strip lights. It is a synthetic elastomer known for its excellent flexibility, durability, and resistance to a wide range of environmental factors. Silicone can withstand extreme temperatures, from freezing cold to high heat, without cracking or losing its flexibility. This makes it suitable for both outdoor winter landscapes and areas with intense sunlight.

In addition to temperature resistance, silicone is highly resistant to UV radiation, which can cause degradation in other materials over time. This property ensures that the color and integrity of the silicone sheathing remain intact, even after prolonged exposure to sunlight. Moreover, silicone is non-toxic, making it a safe choice for applications where human contact may occur, such as in residential and public spaces.

The combination of the IP68 rating and silicone material creates a robust and reliable lighting solution that can thrive in the most demanding environments.

Technical Architecture and Design Features

LED and Circuitry Design

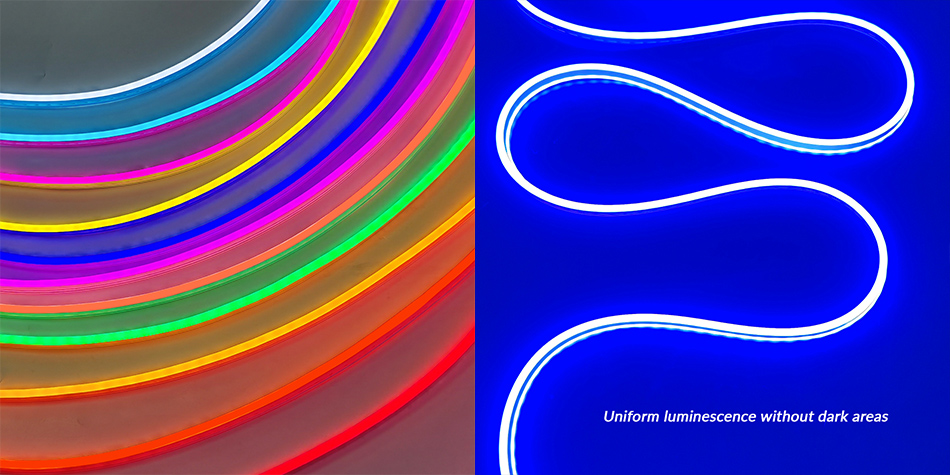

IP68-rated waterproof silicone neon strip lights typically feature high-quality SMD (Surface Mount Device) LEDs. These LEDs are densely packed along the strip, providing uniform illumination and a wide range of color options. The LED chips are mounted on a flexible printed circuit board (PCB), which serves as the electrical pathway for power distribution.

To ensure waterproofing, the entire PCB and LED assembly are encapsulated within the silicone sheath. This encapsulation process not only protects the components from water and dust but also provides mechanical support, enhancing the overall durability of the strip. Specialized waterproof connectors are used to join multiple strips together, maintaining the IP68 integrity of the entire lighting system.

Power and Control Systems

These strip lights usually operate at low voltages, which not only enhances safety but also makes them compatible with a variety of power sources. A dedicated power supply unit is used to convert the standard electrical voltage to the appropriate low voltage for the strip lights.

For color-changing and dynamic lighting effects, many IP68-rated strip lights are equipped with RGB (Red-Green-Blue) or RGBW (Red-Green-Blue-White) technology. They can be controlled using various methods, including wired controllers, wireless remote controls, or smart home integration systems. Some advanced models even support Bluetooth or Wi-Fi connectivity, allowing users to adjust the lighting settings via a mobile app, creating custom lighting scenes and effects with ease.

Thermal Management

Effective thermal management is crucial for the performance and longevity of LED strip lights. The silicone material, along with the design of the PCB, helps in dissipating heat generated by the LEDs. The flexible nature of the strip also allows for better heat distribution, preventing hotspots that could potentially damage the LED chips. This ensures that the strip lights can operate continuously at optimal performance levels, even in high-temperature environments.

Design Flexibility and Customization

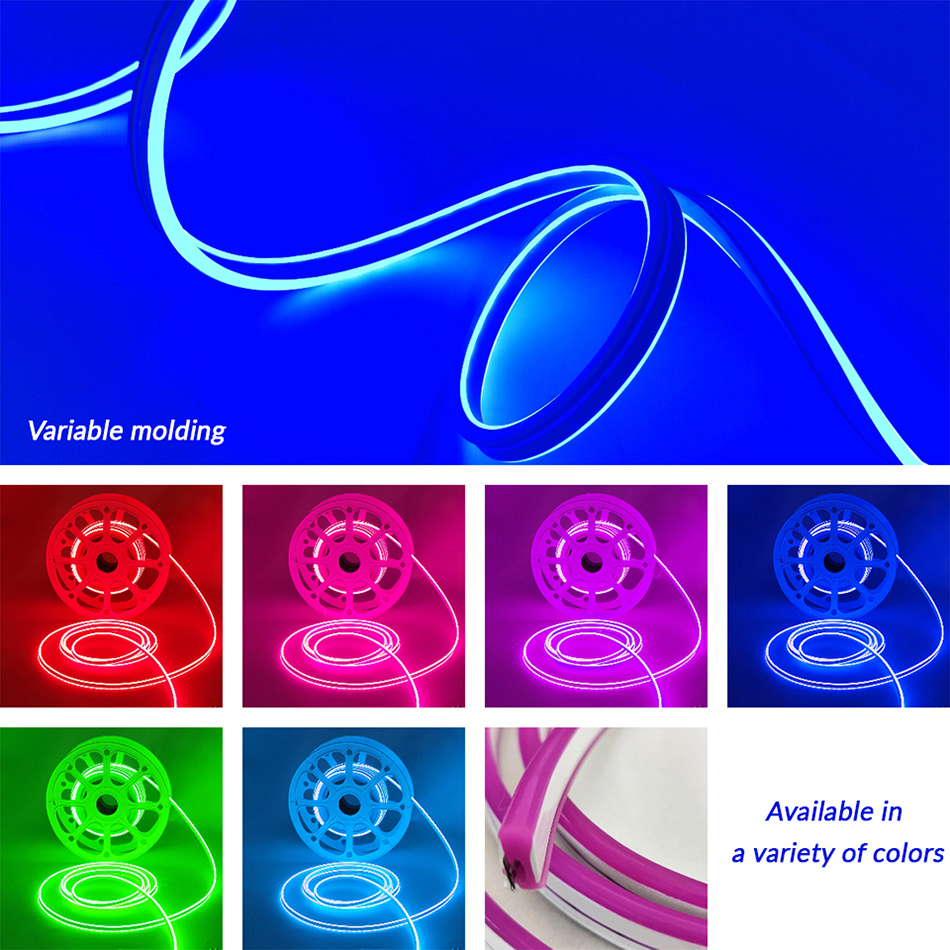

Bendability and Shape Adaptation

One of the key advantages of IP68-rated waterproof silicone neon strip lights is their exceptional flexibility. The silicone sheath allows the strips to bend, curve, and wrap around various surfaces with ease. This makes them suitable for a wide range of applications, from outlining curved architectural features and decorative elements to creating unique lighting patterns on irregular surfaces.

They can be installed on cylindrical columns, arched doorways, or even around the contours of swimming pools. The ability to conform to different shapes enables designers to unleash their creativity and create visually stunning lighting installations that are both functional and aesthetically pleasing.

Length and Configuration Options

These strip lights are available in various standard lengths, and many can also be cut at specific intervals to fit the requirements of a particular project. Additionally, multiple strips can be connected together using waterproof connectors, allowing for the creation of longer lighting runs. This modularity provides great flexibility in designing lighting systems for both small-scale and large-scale projects.

Whether it's a small backyard pond lighting project or a large-scale outdoor event with extensive lighting requirements, IP68-rated waterproof silicone neon strip lights can be easily configured to meet the specific needs of the application.

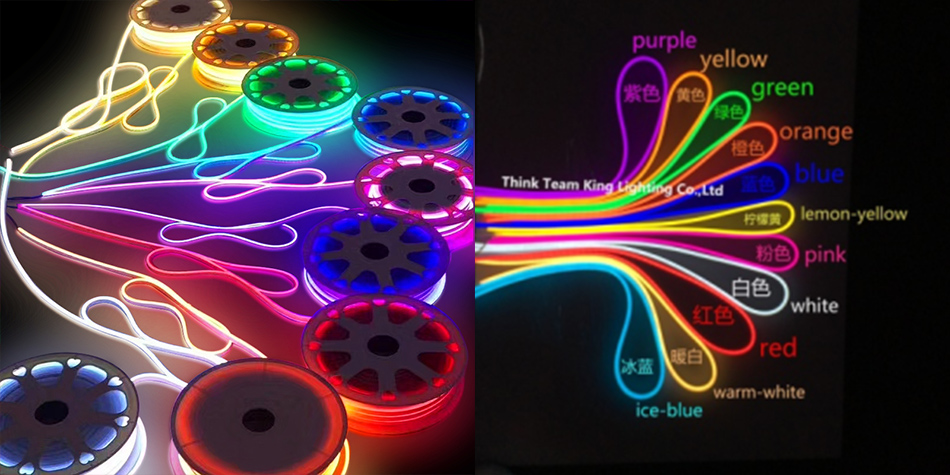

Color and Lighting Effect Customization

With RGB or RGBW technology, these strip lights offer a vast spectrum of colors and lighting effects. Users can choose from a wide range of pre-set colors and effects, or create their own custom combinations. For example, in a poolside setting, the lights can be set to a calming blue hue during the evening to create a serene atmosphere, or changed to vibrant colors for a pool party.

Advanced control systems also allow for dynamic lighting effects such as fades, strobes, and color-changing animations. These effects can be synchronized with music or other external triggers, adding an extra layer of excitement and interactivity to the lighting installation.

Diverse Applications Across Industries

Outdoor Architectural and Landscape Lighting

Building Facades: IP68-rated waterproof silicone neon strip lights are commonly used to outline the edges and features of building exteriors. They can highlight architectural details, create a dramatic nighttime silhouette, and enhance the overall aesthetic appeal of the building. Whether it's a modern skyscraper or a historic structure, these lights can transform the appearance of the building after dark.

Gardens and Landscapes: In gardens and landscapes, these strip lights are used to illuminate pathways, flower beds, and trees. They provide safe and beautiful lighting for outdoor spaces, allowing people to enjoy their gardens even at night. They can also be installed around water features such as ponds, fountains, and waterfalls, creating a magical and enchanting atmosphere.

Pool and Spa Environments

Pool Edges and Steps: Installed along the edges and steps of swimming pools, these strip lights not only add a touch of elegance but also enhance safety by clearly marking the boundaries and steps. The waterproof feature ensures that they can operate reliably underwater or in the wet environment around the pool.

Spa Areas: In spa environments, IP68-rated strip lights can be used to create a relaxing and luxurious atmosphere. Soft, warm lighting can be used to soothe and unwind, while color-changing options can be used to add a bit of fun and variety to the spa experience.

Marine and Coastal Applications

Boats and Yachts: On boats and yachts, these strip lights are used for both interior and exterior lighting. They can be installed in cabins, on decks, and around the hull. The waterproof and durable nature of the lights makes them ideal for the harsh marine environment, where they are exposed to saltwater, wind, and sunlight.

Coastal Buildings and Structures: Buildings and structures located near the coast, such as beachfront hotels and restaurants, can use these strip lights for outdoor lighting. They can withstand the corrosive effects of salt spray and the high humidity levels in coastal areas, providing reliable and long-lasting illumination.

Industrial and Commercial Settings

Warehouses and Factories: In industrial settings, where there may be exposure to water, dust, and other contaminants, IP68-rated waterproof silicone neon strip lights can be used for task lighting, safety lighting, and general illumination. They can withstand the rigors of industrial environments and provide reliable lighting for workers.

Commercial Refrigeration: In commercial refrigeration units, such as walk-in freezers and coolers, these strip lights are used for interior lighting. The ability to operate in low-temperature environments and resist moisture makes them a perfect choice for these applications.

Installation and Maintenance

Installation Process

Installing IP68-rated waterproof silicone neon strip lights requires careful planning and attention to detail to ensure the integrity of the waterproofing. The first step is to prepare the surface where the strips will be installed. The surface should be clean, dry, and free of any debris.

For most applications, the strips come with a self-adhesive backing, which allows for easy installation on smooth surfaces. However, for more secure installations or on rough surfaces, additional mounting accessories such as clips or brackets may be required. When connecting multiple strips together, it is essential to use the appropriate waterproof connectors and ensure that the connections are properly sealed.

The power supply unit should be installed in a dry, protected location, and the electrical connections should be made in accordance with local electrical codes and safety standards. After installation, it is recommended to test the lighting system thoroughly to ensure that all functions are working correctly and that the IP68 rating is maintained.

Maintenance Requirements

One of the major advantages of IP68-rated waterproof silicone neon strip lights is their low maintenance nature. The durable silicone material and the sealed design protect the internal components from damage, reducing the need for frequent repairs or replacements.

Regular cleaning is usually the only maintenance required. A soft, damp cloth can be used to wipe the surface of the strips to remove any dirt or debris. It is important to avoid using harsh chemicals or abrasive materials, as these can damage the silicone sheath.

Periodically, it is also a good idea to check the electrical connections and the waterproof connectors to ensure that they are still secure and properly sealed. In the event of a malfunction or damage, most strip lights have modular designs, allowing for easy replacement of individual segments without having to replace the entire strip.

Advantages over Other Lighting Solutions

Superior Waterproof and Dustproof Performance

Compared to other lighting solutions with lower IP ratings or no waterproofing at all, IP68-rated waterproof silicone neon strip lights offer unparalleled protection against water and dust. This makes them suitable for applications where other lights would quickly fail, such as underwater lighting, outdoor lighting in rainy regions, or lighting in dusty industrial environments.

Durability and Longevity

The combination of the high-quality silicone material and the robust IP68 design ensures that these strip lights have a long lifespan. They can withstand the rigors of harsh environments, including extreme temperatures, UV radiation, and mechanical stress. This durability reduces the frequency of replacements, resulting in cost savings over the long term.

Energy Efficiency

Like other LED-based lighting solutions, IP68-rated waterproof silicone neon strip lights are highly energy-efficient. They consume significantly less power than traditional incandescent or fluorescent lights while providing the same or even better illumination. This not only helps to reduce electricity bills but also makes them a more environmentally friendly lighting option.

Design Flexibility

As mentioned earlier, the flexibility of these strip lights allows for a wide range of creative design possibilities. They can be easily adapted to different shapes and surfaces, enabling designers to create unique and customized lighting installations that are not possible with rigid lighting fixtures.

Innovations and Future Trends

Smart Integration

The future of IP68-rated waterproof silicone neon strip lights lies in smart integration. With the increasing popularity of smart home and Internet of Things (IoT) technologies, these lights are expected to become more connected and intelligent. Integration with voice control systems such as Amazon Alexa and Google Assistant will allow users to control the lights using simple voice commands.

Advanced sensors can also be integrated into the strip lights to enable features such as automatic on/off based on motion or ambient light levels, and real-time monitoring of the light's performance and status. This smart integration will not only enhance the user experience but also improve the energy efficiency and functionality of the lighting systems.

Advanced Materials and Manufacturing Techniques

Research is ongoing to develop even more advanced silicone materials with improved properties. New materials may offer enhanced flexibility, better heat resistance, and increased durability. Additionally, advancements in manufacturing techniques will allow for more precise production of the strip lights, resulting in better quality and more consistent performance.

For example, 3D printing technology may be used to create custom-shaped silicone sheaths for unique lighting applications. Nanotechnology may also be applied to improve the properties of the silicone material at the molecular level, further enhancing the performance of the strip lights.

Color and Lighting Effect Advancements

Future IP68-rated waterproof silicone neon strip lights are likely to offer even more advanced color and lighting effect options. New LED technologies may enable the production of more vibrant and accurate colors, as well as the creation of more complex and dynamic lighting effects.

For example, holographic lighting effects and real-time color mapping based on external data sources (such as weather conditions or social media trends) may become possible. These advancements will open up new creative possibilities for designers and enhance the visual impact of lighting installations.