Time:2025-08-12

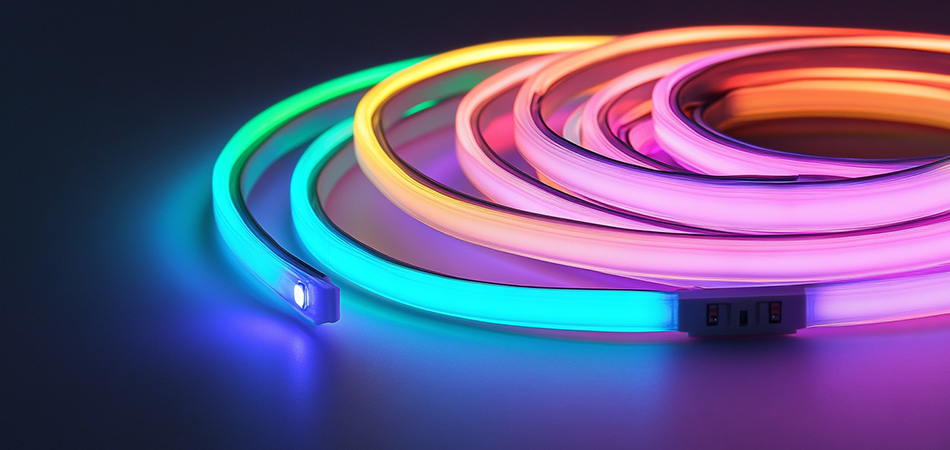

A Manufacturer of Silicone Neon Light Strip plays a pivotal role in bridging innovation and practicality in the lighting industry. These manufacturers are not merely producers but architects of illumination, combining technical expertise with creative design to deliver products that meet the diverse needs of residential, commercial, and industrial clients. As demand for durable, flexible, and energy-efficient lighting grows, the role of these manufacturers becomes increasingly critical—they transform raw materials into high-performance silicone neon strips that redefine how spaces are lit. This article explores the manufacturing processes, quality control measures, customization capabilities, industry partnerships, and sustainability practices of a leading Manufacturer of Silicone Neon Light Strip, highlighting their contribution to advancing modern lighting solutions.

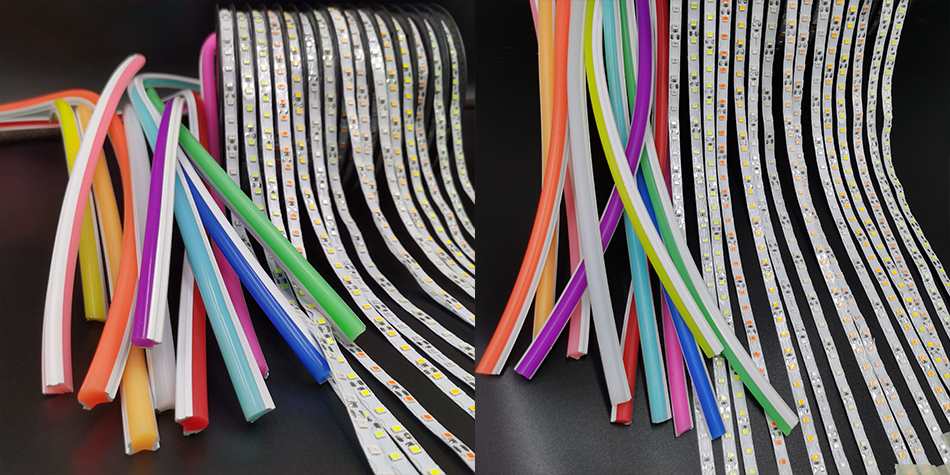

The journey of a silicone neon light strip from concept to completion involves a series of precise processes that ensure consistency, durability, and performance. Material sourcing is the first critical step, with reputable manufacturers carefully selecting high-grade components. This includes medical-grade silicone for casings, which offers superior flexibility, heat resistance, and UV stability; high-performance LEDs (light-emitting diodes) that deliver uniform brightness and color accuracy; and flexible circuit boards made from polyimide, chosen for their ability to withstand repeated bending without compromising conductivity. Manufacturers often partner with certified suppliers to ensure materials meet international standards for safety and sustainability.

Circuit board assembly is a precision-driven process, where automated machinery places surface-mounted LEDs (SMDs) onto the flexible circuit boards at calibrated intervals. This ensures uniform light distribution, eliminating the "dot effect" common in lower-quality strips. The circuit boards are then tested for conductivity, with each connection verified to ensure consistent electrical flow—critical for maintaining even brightness across the strip’s length. Manual inspections complement automated testing, with technicians checking for any defects in soldering or component placement.

Silicone extrusion is the process that gives the strip its protective casing. Molten silicone is extruded around the assembled circuit board in a continuous process, forming a seamless, translucent layer that shields internal components from dust, moisture, and physical damage. The extrusion process is carefully controlled to ensure uniform thickness, which is essential for consistent light diffusion. Manufacturers may add additives to the silicone during this stage to enhance specific properties—such as UV inhibitors for outdoor strips or flame retardants for commercial applications.

Cutting and finishing complete the manufacturing process. The continuous strip is cut to standard lengths using precision tools, with pre-marked cut lines added to allow end-users to trim the strip to their specific needs. Reinforced edges are added during this stage, preventing fraying and enhancing durability. Finally, connectors are attached to the strip’s ends, with options including plug-and-play designs for easy installation or solder pads for more permanent setups. Each finished strip undergoes a final inspection, with tests for water resistance (using IP rating standards), light output, and flexibility.

A commitment to quality is what distinguishes leading manufacturers of silicone neon light strips, with rigorous quality control (QC) measures embedded throughout the production cycle. Incoming material inspection ensures that all raw materials—from silicone and LEDs to circuit boards—meet strict specifications. Samples of each material batch are tested for properties like silicone elasticity, LED brightness, and circuit board flexibility, with any non-conforming materials rejected before they enter production.

In-process testing is conducted at every stage of manufacturing to identify and address issues early. During circuit board assembly, automated optical inspection (AOI) systems check for misaligned components or soldering defects. During extrusion, thickness gauges monitor the silicone casing to ensure uniformity, while thermal imaging detects any hot spots that could indicate poor LED placement. These real-time checks prevent defective products from progressing to the next stage, reducing waste and ensuring consistency.

Final product testing is comprehensive, with each batch of silicone neon strips subjected to a battery of tests. This includes:

Brightness and color consistency: Using spectrophotometers to verify that light output and color temperature match specifications, ensuring uniformity across the strip and between batches.

Environmental resistance: Testing strips in controlled chambers to simulate extreme temperatures, humidity, and UV exposure, ensuring they perform in outdoor or harsh indoor environments.

Flexibility and durability: Subjecting strips to repeated bending and twisting tests to ensure they maintain functionality after prolonged use, a critical measure for applications requiring contouring to surfaces.

Electrical safety: Verifying compliance with international standards (such as CE, UL, or RoHS) through tests for insulation resistance, voltage endurance, and protection against short circuits.

Traceability systems allow manufacturers to track each strip from raw material to delivery, with unique identifiers linked to production data, test results, and batch information. This enables quick resolution of any issues and provides transparency for clients, who can request documentation of testing and compliance for their specific order.

A key strength of a leading Manufacturer of Silicone Neon Light Strip is its ability to offer customized solutions, adapting products to meet the unique requirements of diverse clients. Length and shape customization allows clients to order strips in non-standard lengths, eliminating the need for on-site cutting and reducing waste. For specialized applications—such as curved signage or architectural accents—manufacturers can produce pre-formed strips that maintain uniform light output even in complex shapes, achieved through precise LED placement and circuit board design.

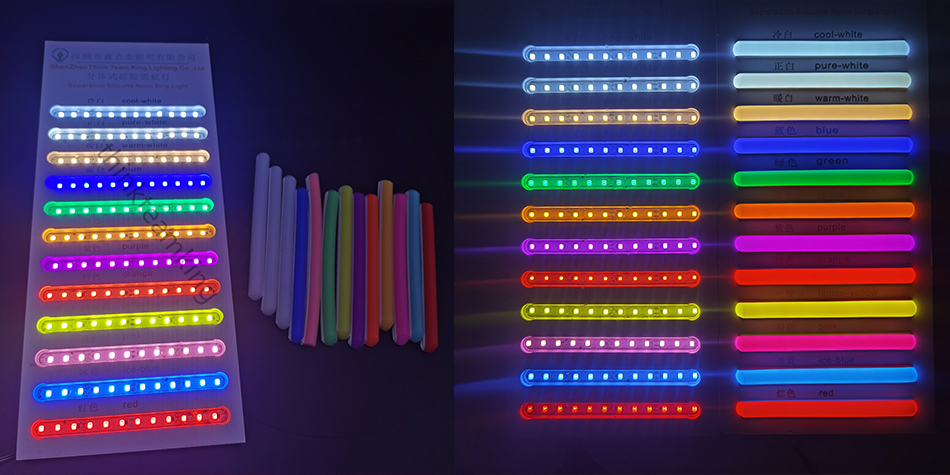

Color and light output customization caters to specific aesthetic or functional needs. Clients can choose from a range of single-color LEDs (including warm white, cool white, and bold hues like red, blue, or green) or opt for RGB (red-green-blue) strips that offer dynamic color changing. Tunable white strips, which adjust between warm and cool tones, are also available for environments where lighting needs to adapt to different times of day or activities. Manufacturers work with clients to calibrate color temperatures and brightness levels, ensuring the final product aligns with their vision.

Casing and material customization allows for adaptation to unique environments. For example, outdoor projects may require silicone casings with enhanced UV resistance, while industrial applications might need flame-retardant materials. Manufacturers can also adjust casing thickness or opacity, with options ranging from fully translucent (for maximum brightness) to semi-opaque (for softer, diffused light). Specialized casings, such as those with matte finishes to reduce glare or anti-microbial properties for healthcare settings, are also available.

Integration with smart systems is another area of customization, with manufacturers offering strips compatible with Bluetooth, Wi-Fi, or DMX controllers. This allows clients to incorporate features like remote dimming, color synchronization, or scheduling into their lighting systems. Manufacturers can pre-install controllers or include custom wiring to simplify integration with existing smart home or building management systems.

Successful manufacturers of silicone neon light strips thrive on strong partnerships and collaborative relationships with clients, distributors, and industry stakeholders. Client collaboration begins with a thorough consultation to understand the client’s needs—whether it’s a residential project requiring subtle ambient lighting or a commercial installation demanding high-visibility signage. Manufacturers provide technical expertise, offering recommendations on material selection, design, and installation to ensure the final product meets both aesthetic and functional requirements. Prototyping services allow clients to test samples before full production, ensuring satisfaction and reducing the risk of costly revisions.

Distributor and retailer partnerships are critical for expanding market reach. Manufacturers work closely with distributors to ensure timely delivery, provide training on product features and installation, and offer marketing support. This collaboration helps retailers better serve end-users, with access to detailed product information and technical support. Manufacturers may also develop exclusive product lines for key distributors, tailored to regional market preferences or regulatory requirements.

Architect and designer partnerships drive innovation, with manufacturers collaborating on large-scale projects such as building facades, museum installations, or hospitality spaces. These partnerships often involve co-creation, where manufacturers adapt products to meet the unique design challenges of a project—such as extreme weather resistance for a skyscraper exterior or custom color matching for a luxury hotel. By involving manufacturers early in the design process, architects and designers can leverage technical capabilities to bring ambitious lighting concepts to life.

Industry certification partnerships ensure compliance with global standards. Manufacturers work with organizations like UL (Underwriters Laboratories), CE (Conformité Européenne), and RoHS (Restriction of Hazardous Substances) to obtain certifications, demonstrating their commitment to safety and sustainability. These partnerships not only validate product quality but also facilitate market access, as many clients and regions require certified products.

In an era of growing environmental awareness, leading manufacturers of silicone neon light strips are prioritizing sustainability, integrating eco-friendly practices into every stage of production. Material sustainability is a key focus, with manufacturers sourcing recycled or renewable materials where possible. This includes using silicone derived from plant-based sources, recycled copper for circuit boards, and LEDs that contain no hazardous substances. By reducing reliance on virgin materials, manufacturers minimize their carbon footprint and support circular economy principles.

Energy-efficient production reduces the environmental impact of manufacturing processes. This includes using energy-saving machinery, optimizing production schedules to minimize idle time, and switching to renewable energy sources (such as solar or wind power) for factory operations. Some manufacturers also implement energy recovery systems, capturing waste heat from extrusion processes to warm facilities or preheat materials, further reducing energy consumption.

Waste reduction strategies are implemented throughout production. Scrap materials from cutting and extrusion are recycled—silicone scraps, for example, are melted down and reused in non-critical components, while defective circuit boards are stripped of usable LEDs and metals. Manufacturers also design products for longevity, using durable materials that reduce the need for frequent replacements, and for recyclability, ensuring that components can be separated and recycled at the end of the product’s lifespan.

Eco-friendly packaging minimizes waste in distribution. Manufacturers use recyclable or biodegradable packaging materials, avoid excessive packaging, and design reusable containers for bulk shipments. Some also offer take-back programs, allowing clients to return used strips for recycling, ensuring that valuable materials are recovered rather than sent to landfills.

A forward-thinking Manufacturer of Silicone Neon Light Strip stays ahead of market trends, anticipating shifts in consumer demand and technological advancements to maintain industry leadership. Smart lighting integration is a major trend, with manufacturers developing strips compatible with the Internet of Things (IoT). These strips can be controlled via smartphone apps, voice assistants, or home automation systems, offering features like color changing, scheduling, and synchronization with music or other smart devices. Leading manufacturers are also exploring AI-driven lighting, where strips adjust automatically based on user behavior or ambient conditions.

Sustainability as a differentiator is increasingly important, with clients prioritizing eco-friendly products. Manufacturers are responding by obtaining green certifications, publishing sustainability reports, and developing carbon-neutral production processes. This not only meets client demand but also reduces long-term costs through energy and waste savings.

Customization for niche markets is growing, with manufacturers developing specialized strips for industries like healthcare (anti-microbial casings), agriculture (grow light spectrums), and automotive (interior accent lighting). These niche products require deep industry knowledge and technical expertise, allowing manufacturers to differentiate themselves from competitors.

Global market expansion is another focus, with manufacturers adapting products to meet regional regulations and preferences. This includes designing strips for specific voltage requirements, obtaining local certifications, and offering region-specific colors or features. By understanding local markets, manufacturers can build strong partnerships and increase their global footprint.

A Manufacturer of Silicone Neon Light Strip is more than a producer—it is a driver of innovation, quality, and sustainability in the lighting industry. Through precise manufacturing processes, rigorous quality control, and a commitment to customization, these manufacturers deliver products that transform spaces, from cozy homes to iconic commercial buildings. Their ability to adapt to market trends, collaborate with clients, and prioritize sustainability ensures they remain at the forefront of lighting technology.

As the demand for flexible, durable, and energy-efficient lighting continues to grow, the role of these manufacturers will only become more critical. By combining technical expertise with creative vision, they are not just making silicone neon light strips—they are shaping the future of illumination, one strip at a time.