Time:2025-07-26

In the realm of architectural lighting, precision-cuttable strips have emerged as a transformative solution for illuminating building edges with unparalleled accuracy and design flexibility. These specialized lighting strips are engineered to align seamlessly with the intricate contours, angles, and dimensions of architectural features—from sharp corners and curved facades to subtle trim lines—enabling designers to translate visionary concepts into illuminated reality. Unlike rigid lighting systems that force compromises in design, precision-cuttable strips adapt to the unique geometry of architectural edges, ensuring clean lines, uniform illumination, and harmonious integration with the building’s aesthetic. This article explores their engineering innovations, technical capabilities, applications across building types, installation methodologies, and selection criteria, highlighting their role in elevating architectural lighting from functional necessity to design artistry.

Engineering Precision: The Core of Cuttable Architectural Strips

Precision Cutting Mechanics

Strategic Cut Line Placement: At the foundation of these strips lies a sophisticated design with precisely calibrated cut lines, positioned at intervals that align with common architectural dimensions and angles. These lines are engineered to separate LED clusters and circuit pathways without disrupting functionality, allowing installers to trim the strip to exact lengths—whether for a 90-degree corner, a gentle curve, or a custom linear segment—with micron-level accuracy.

Flexible Substrate Technology: The strips are constructed on ultra-thin, high-tensile substrates, often reinforced with fiberglass or composite materials, that combine flexibility with structural stability. This substrate bends smoothly around radii as tight as a few centimeters while maintaining rigidity along straight runs, ensuring the strip follows architectural edges without sagging, warping, or creating unsightly gaps.

Seamless Segment Integration: Each cut segment retains independent electrical continuity, thanks to modular circuitry that isolates power distribution between sections. This allows designers to create multi-piece installations—such as illuminating a building’s roofline, window frames, and base trim with a single strip type—while ensuring consistent light output across all connected segments.

Architectural-Grade Durability

Material Engineering for Building Environments: The strips feature housing materials tailored to architectural demands, including UV-resistant silicone, weatherproof polycarbonate, or fire-retardant PVC. These materials withstand extreme temperature fluctuations, exposure to sunlight, moisture, and physical abrasion—critical for outdoor edges, high-traffic indoor areas, or industrial facilities.

Impact and Vibration Resistance: Reinforced edges and shock-absorbent substrates protect against accidental damage during installation (e.g., from ladders or tools) and long-term wear from environmental factors like wind-induced vibration on building facades. This durability ensures the strips maintain their structural and optical integrity over decades of use.

Compatibility with Building Materials: The strips are designed to adhere or mount to common architectural surfaces, including concrete, metal, glass, stone, and wood, without causing chemical reactions or material degradation. Specialized adhesives or mounting systems prevent staining, corrosion, or discoloration, preserving the building’s finish.

Technical Capabilities for Architectural Excellence

Light Output and Aesthetic Control

Uniform Edge Illumination: Advanced LED spacing and diffused optics eliminate hotspots and shadows, creating a continuous, evenly distributed glow along architectural edges. This uniformity is critical for highlighting design details—whether emphasizing the sleek lines of a modernist facade or softening the edges of a historic building’s trim work.

Color Temperature and CRI Optimization: Strips are available in a range of color temperatures (from warm amber to cool white) and high Color Rendering Index (CRI) options, ensuring they complement the building’s materials and lighting design intent. Warm tones enhance natural materials like wood or stone, while cool tones accentuate metal or glass in contemporary designs.

Dimming and Dynamic Control: Integration with architectural lighting control systems (e.g., DMX512, DALI, or smart building platforms) allows precise dimming and dynamic effects. This enables designers to adjust brightness for different times of day (brighter for daytime visibility, softer for evening ambiance) or create subtle transitions that highlight the building’s form after dark.

Adaptability to Architectural Complexity

Angle and Curve Compatibility: The strips’ flexibility extends to compound angles and irregular shapes, making them suitable for complex architectural features like domes, arches, or parametric facades. Specialized corner connectors and flexible joints allow seamless transitions between linear and curved segments, preserving the illusion of a continuous light line.

Low-Profile Design: Ultra-thin profiles (often less than a few centimeters in thickness) ensure the strips remain unobtrusive during daylight hours, avoiding visual disruption of the building’s facade or interior design. This low-profile nature allows installation in narrow recesses, between material joints, or behind trim—hiding the hardware while maximizing light projection along edges.

Custom Length Scalability: Whether illuminating a small window sill or an entire high-rise facade, the strips scale to project requirements. Long-length reels (with cut lines at frequent intervals) minimize splices for large installations, while short-cut segments work for intimate details like staircase nosings or cabinet edges.

Applications Across Architectural Edges

Exterior Building Facades

Facade centour lighting: Precision-cuttable strips highlight the perimeter of building facades, defining their silhouette against the sky. Installed along rooflines, cornices, or floor-to-ceiling edges, they emphasize the building’s height, symmetry, or unique shape—whether a historic mansion’s ornate trim or a modern skyscraper’s angular facade.

Window and Door Edges: Mounted around window frames, doorways, or curtain walls, the strips create a subtle glow that frames these openings, enhancing curb appeal and wayfinding. In commercial buildings, this illumination reinforces brand identity by highlighting entry points or signature architectural features.

Balcony and Railing Accents: For multi-story buildings, strips installed along balcony edges, railings, or parapets add safety lighting while emphasizing the building’s horizontal lines. Their weather resistance ensures reliable performance in rain, snow, or coastal salt spray.

Interior Architectural Details

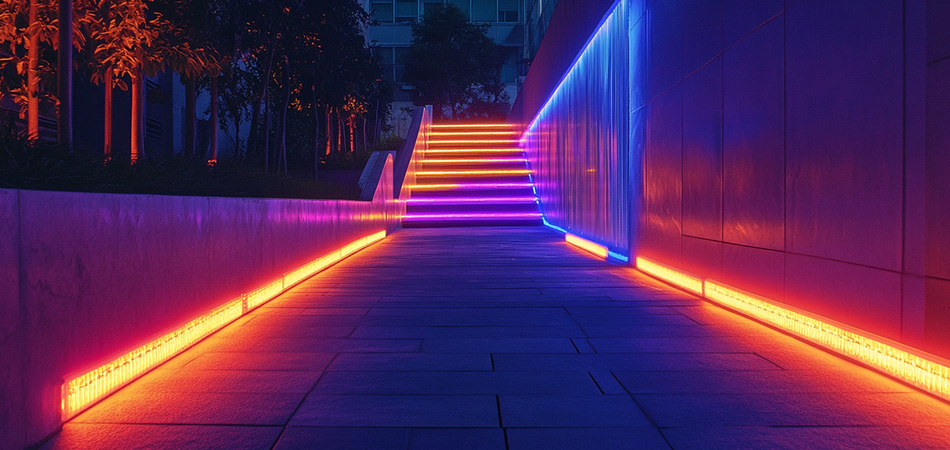

Staircase and Railings: Along staircase nosings, handrails, or balustrades, precision-cut strips provide ambient lighting that enhances safety (illuminating steps) while highlighting the staircase’s design—whether a grand marble staircase in a hotel lobby or a minimalist floating staircase in a residence.

Ceiling and Wall Transitions: Installed at the junction of ceilings and walls, or along cove moldings, the strips create indirect ambient lighting that softens room edges and adds depth. In spaces like lobbies, museums, or offices, this illumination complements overhead lighting and emphasizes architectural height.

Custom Millwork and Built-Ins: For custom cabinetry, bookshelves, or fireplace mantels, cuttable strips fit precisely into edges and recesses, highlighting craftsmanship without overwhelming the design. Their low profile ensures they remain hidden within millwork, projecting light onto surfaces rather than drawing attention to the hardware.

Specialized Architectural Environments

Cultural and Historic Buildings: In historic preservation projects, these strips illuminate delicate architectural details (e.g., cornices, friezes, or ornamental moldings) without damaging historic materials. Their reversible installation and non-invasive mounting systems preserve the building’s integrity.

Commercial and Retail Spaces: In malls, airports, or retail centers, strips define storefront edges, food court counters, or seating areas, guiding foot traffic and enhancing brand aesthetics. Their dimmable functionality adapts to different times of day, from bright daytime visibility to warm evening ambiance.

Healthcare and Educational Facilities: Along corridor edges, nurse stations, or classroom whiteboards, precision-cut strips provide glare-free ambient lighting that supports functionality while softening institutional aesthetics. Their easy maintenance and durability suit high-usage environments.

Installation Methodology for Architectural Precision

Pre-Installation Planning and Measurement

Laser-Guided Design Mapping: Before installation, architectural teams use laser measuring tools and 3D modeling software to map the building’s edges, identifying cut points, angles, and mounting surfaces. This ensures strips are cut to exact lengths, minimizing waste and ensuring a perfect fit.

Material Compatibility Testing: Samples of the strips are tested on mock-ups of the building’s surfaces (e.g., stone, metal, or painted wood) to verify adhesion, light projection, and material compatibility. This step prevents issues like adhesive failure or discoloration post-installation.

Weather and Environmental Assessment: For exterior installations, wind load calculations, UV exposure analysis, and temperature range testing ensure the strips and mounting systems can withstand local climate conditions—critical for longevity in extreme environments.

Precision Cutting and Preparation

Field-Cutting Protocols: Installers use sharp, fine-toothed blades or specialized cutting tools to trim strips at marked cut lines, ensuring clean edges that fit snugly against architectural features. Post-cut, ends are sealed with manufacturer-recommended caps or sealants to maintain weather resistance and electrical safety.

Connector Integration: For multi-segment installations, weatherproof or fire-rated connectors are used to join strips, with alignment tools ensuring segments form straight lines or precise angles. Connectors are hidden within mounting channels or recesses to maintain visual continuity.

Mounting System Selection: Depending on the surface, mounting options include adhesive backing (for smooth surfaces), mechanical clips (for porous materials), or recessed channels (for seamless integration). For exterior high-rise installations, clips with wind-resistant fasteners prevent displacement during storms.

Installation and Calibration

Positioning and Alignment: Using laser levels and plumb lines, installers ensure strips are perfectly aligned along edges, with consistent spacing from the edge to maintain uniform light projection. For curved surfaces, strips are gently bent to follow the radius, with tension evenly distributed to avoid kinking.

Electrical Integration: Wiring is routed through concealed channels or building cavities, with junction boxes placed at strategic intervals to distribute power evenly. For smart buildings, strips are connected to building management systems, enabling centralized control and scheduling.

Light Calibration: Post-installation, lighting designers use spectrometers and dimming controllers to calibrate light output, ensuring uniform brightness and color across all edge segments. This step fine-tunes the illumination to match the architectural design intent.

Maintenance, Troubleshooting, and Longevity

Proactive Maintenance Practices

Periodic Visual Inspections: Facilities teams conduct regular checks for signs of damage (e.g., cracked housing, loose connections) or light degradation. Exterior strips are inspected seasonally, particularly after extreme weather events, to ensure mounting systems remain secure.

Cleaning Protocols: For interior strips, dust is removed with soft brushes or compressed air. Exterior strips are cleaned with mild detergent and soft cloths to remove dirt, pollen, or salt residue that could dim light output.

Connector and Power Supply Checks: Electrical connections are inspected annually for corrosion or loosening, with contacts cleaned or replaced as needed. Power supplies are tested for voltage stability to prevent premature LED failure.

Troubleshooting Common Architectural Challenges

Uneven Light Output: Caused by misaligned segments or voltage drop in long runs. Solutions include repositioning segments for better alignment or adding intermediate power feeds to distribute voltage evenly.

Adhesion Failure on Textured Surfaces: For porous or rough surfaces, mounting clips or recessed channels replace adhesive backing, ensuring secure attachment without damaging the building’s finish.

Weather-Related Damage: Exterior strips with inadequate UV or moisture resistance may yellow or crack. Upgrading to higher-grade materials (e.g., silicone housing) or adding protective covers resolves these issues.

Selection Criteria for Architectural Edge Strips

Key Performance Metrics

Cut Precision and Interval Flexibility: Choose strips with cut lines spaced to match the building’s edge dimensions—closer intervals for intricate details, wider intervals for long linear runs. Look for clearly marked cut lines and consistent segment performance post-cut.

Environmental Rating: For exteriors, prioritize IP65+ waterproofing, UV resistance, and wide temperature tolerance (-40°C to 60°C). For interiors, focus on fire ratings (e.g., UL 94 V-0) and low VOC emissions to meet indoor air quality standards.

Light Distribution: Opt for strips with diffused optics that project light evenly along edges, avoiding glare or hotspots. Adjustable beam angles (where available) allow customization for different edge widths and surface textures.

Compatibility Considerations

Mounting Surface Adaptability: Ensure the strip’s mounting system works with the building’s materials—adhesive for smooth surfaces, mechanical clips for stone or brick, or magnetic mounts for metal surfaces.

Control System Integration: Verify compatibility with the building’s lighting control system (e.g., DALI, DMX, or BACnet) to enable centralized management, scheduling, and dimming. Smart-enabled strips should integrate with building automation platforms.

Long-Term Availability: Select strips from manufacturers with a track record of product consistency, ensuring replacement segments or accessories will be available for future repairs or expansions.

Future Trends in Architectural Edge Lighting

Smart Edge Integration: Upcoming strips will feature embedded sensors (e.g., motion, light, or temperature) that adjust illumination based on environmental conditions—brightening when pedestrians approach building entrances or dimming during daylight hours to save energy.

Sustainable Materials: Manufacturers are developing strips with recycled housing materials, energy-efficient LEDs (e.g., 200+ lumens per watt), and biodegradable adhesives, aligning with green building standards like LEED or BREEAM.

3D Printing Compatibility: Custom mounting brackets and connectors will be 3D-printed on-site, allowing perfect adapt to unique architectural edges and reducing installation time. This on-demand manufacturing minimizes waste and supports complex designs.

Conclusion: Precision as a Design Catalyst

Precision-cuttable strips for architectural edges have redefined how designers approach building illumination, transforming functional lighting into an integral part of architectural expression. By combining engineering precision with flexible design, these strips enable architects to highlight a building’s unique edges, angles, and details with unprecedented accuracy—whether enhancing a historic landmark or defining a contemporary skyline.

Their durability, adaptability, and seamless integration with building materials ensure they perform reliably for decades, while their installation flexibility supports both new construction and retrofit projects. As architectural lighting continues to evolve, these strips will remain a cornerstone of design, proving that precision and creativity can coexist to elevate the built environment.

For architects, builders, and designers seeking to turn visionary concepts into illuminated reality, precision-cuttable strips for architectural edges offer the perfect blend of technical performance and design freedom—where every edge becomes an opportunity to tell a building’s story through light.