Time:2025-07-21

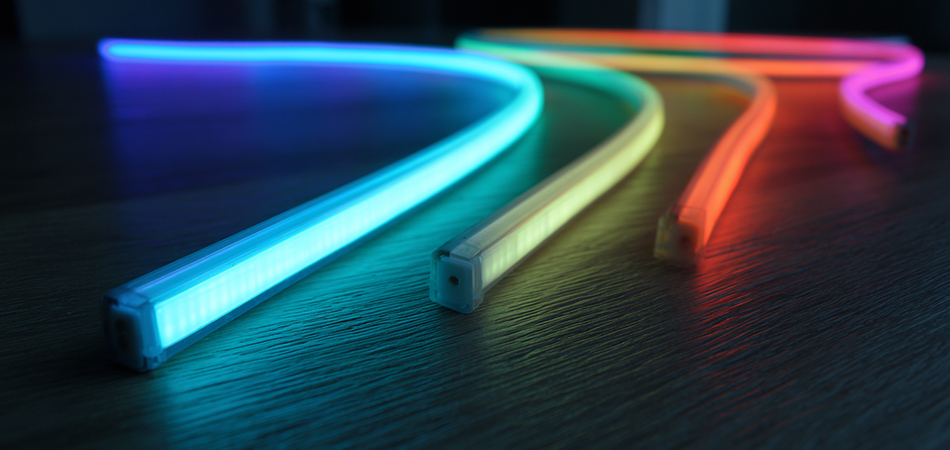

In the realm of modern lighting, cuttable RGB neon light strips stand as a cornerstone of flexibility, offering users the ability to tailor illumination to the unique dimensions of any space. These strips combine the vibrant color capabilities of RGB technology with the practicality of precision cutting, allowing for seamless integration into diverse environments—from residential interiors to commercial displays and architectural accents. Unlike rigid lighting fixtures or fixed-length strips, cuttable RGB neon strips empower users to trim, shape, and install lighting with unparalleled accuracy, eliminating waste and ensuring a perfect fit for any project. This article explores their design innovations, cutting techniques, installation processes, application versatility, and key considerations for selection, highlighting their role as a foundational tool in customizable lighting design.

The Design and Construction of Cuttable RGB Neon Light Strips

Core Structural Components

Flexible Substrate and LED Integration: Cuttable RGB neon strips are built on a thin, bendable substrate—typically fiberglass or polyimide—that supports densely packed RGB LED chips. Each LED combines red, green, and blue emitters, enabling millions of color combinations through precise control. The substrate is reinforced along cut lines to maintain structural integrity, ensuring the strip remains functional even after trimming.

Protective Silicone Encapsulation: A durable, translucent silicone housing encases the LEDs and circuitry, providing protection against dust, moisture, and minor physical impacts. This encapsulation diffuses light evenly, creating a smooth, neon-like glow without harsh hotspots, while allowing flexibility for installation on curved or irregular surfaces.

Precision-Cut Architecture: Strips feature laser-marked cut lines at regular intervals, aligned with copper contact pads that facilitate electrical continuity after cutting. These lines ensure that users can trim the strip to exact lengths without damaging internal components, with each cut segment retaining full functionality when connected to power or other segments.

Key Performance Features

Color Accuracy and Consistency: High-quality cuttable RGB strips utilize tight color binning, ensuring uniform color output across the entire strip and between cut segments. This consistency is critical for applications where color matching is essential, such as brand displays or coordinated room lighting.

Energy Efficiency: LED technology ensures these strips consume minimal power while delivering bright, vibrant illumination. This efficiency reduces energy costs and heat generation, making them suitable for extended use in enclosed spaces or heat-sensitive environments.

Environmental Adaptability: Available in various IP ratings, cuttable RGB neon strips cater to both indoor (IP20) and outdoor (IP65/IP68) applications. Waterproof models feature sealed silicone housing and reinforced connections, withstand rain, humidity, and temperature fluctuations, expanding their usability to gardens, patios, and damp indoor areas like bathrooms.

Cutting Techniques and Best Practices for Precision

Tools and Preparation for Cutting

Recommended Cutting Tools: To achieve clean, accurate cuts, use sharp, non-serrated scissors or a utility knife with a fresh blade. Dedicated LED strip cutters—featuring guided blades—are ideal for ensuring straight cuts, particularly for users with limited experience. Avoid dull tools, as they can crush the silicone housing or damage internal LEDs.

Identifying Cut Lines: Locate the laser-marked cut lines on the strip, which are typically accompanied by symbols or icons indicating valid cutting points. These lines align with the strip’s internal circuitry, ensuring that cut segments retain working LEDs and functional contact pads. Never cut between marked lines, as this will render the segment non-functional.

Surface Preparation: Before cutting, place the strip on a flat, stable surface to prevent slipping. For longer strips, secure the uncut portion with tape or weights to maintain stability during cutting, ensuring the blade follows the marked line precisely.

Step-by-Step Cutting Process

Measurement and Marking: Measure the target length and mark the corresponding cut line with a pencil or tape, double-checking to avoid cutting too short. Add a small buffer (1–2 cm) if unsure, as trimming further later is easier than extending a too-short segment.

Making the Cut: Align the tool with the marked cut line, applying steady, even pressure to slice through the strip in one smooth motion. For utility knives, use a straightedge as a guide to ensure a perpendicular cut, reducing the risk of damaging adjacent LEDs or contact pads.

Post-Cutting Inspection: After cutting, inspect the end of the strip to ensure the cut is clean and straight, with no silicone burrs or bent contact pads. Remove any debris with a soft cloth, as obstructions can hinder connector attachment or electrical conductivity.

Avoiding Common Cutting Mistakes

Preventing Damage to LEDs: Ensure the cut line is positioned between LEDs, not through an LED chip, to avoid rendering the segment inoperable. Most strips space LEDs evenly, with cut lines placed midway between chips to protect components.

Maintaining Contact Pad Integrity: Avoid bending or scraping the copper contact pads during cutting, as damaged pads can disrupt electrical connections. If pads are slightly oxidized, gently clean them with isopropyl alcohol and a soft brush before connecting.

Handling Waste Responsibly: Dispose of cut-off segments properly, as they may contain small electronic components. Many manufacturers offer recycling programs for LED strips, reducing environmental impact from waste.

Installation and Connection Methods for Cuttable RGB Neon Strips

Basic Installation Steps

Surface Preparation: Clean the installation surface with a dry cloth or alcohol to remove dust, grease, or debris, ensuring the strip’s adhesive backing bonds securely. For textured or porous surfaces (brick, wood), use mounting clips or channels to reinforce adhesion.

Adhesive Application: Peel the protective film from the strip’s adhesive backing, aligning the strip with the desired layout. Press firmly along the entire length to activate the adhesive, focusing on edges and corners to prevent lifting over time. For curved surfaces, apply pressure incrementally as the strip conforms to the shape.

Securing Longer Runs: For strips longer than 2–3 meters, use additional mounting clips spaced 30–50 cm apart to prevent sagging, particularly in overhead installations or high-traffic areas. Aluminum channels can also be used to protect the strip and create a polished, finished look.

Connecting Cut Segments and Extensions

Solderless Connectors: To join cut segments or extend the strip, use solderless snap connectors designed for RGB neon strips. These connectors feature pins that align with the strip’s contact pads, creating a secure electrical connection when clamped shut. Choose connectors matching the strip’s width and IP rating for optimal performance.

Wiring for Power Distribution: For longer installations, connect strips to a power supply using compatible wiring harnesses, ensuring the power supply’s capacity matches the total length of connected segments. Use power injection connectors for runs exceeding the strip’s maximum continuous length, preventing voltage drop and ensuring uniform brightness.

Controller Integration: Connect the strip to an RGB controller—either basic remote-controlled models or smart WiFi/Bluetooth-enabled units—to access color adjustment, brightness control, and dynamic effects. Ensure the controller supports the strip’s LED configuration (RGB or RGBW) for full functionality.

Tips for Professional-Quality Installation

Concealing Wires and Connections: Use cable management clips, channels, or raceways to hide wires and connectors, maintaining a clean, uncluttered appearance. For exposed installations, choose low-profile connectors and paint them to match the surface color.

Testing Before Final Mounting: Test the strip and connections before fully securing the strip to the surface, ensuring all LEDs illuminate and the controller functions correctly. This allows for easy troubleshooting of loose connections or faulty segments before permanent installation.

Weatherproofing for Outdoor Use: For outdoor installations, seal connections with silicone sealant to prevent moisture ingress, even with waterproof strips and connectors. Use UV-resistant mounting tape or clips to withstand sun exposure and temperature fluctuations.

Applications of Cuttable RGB Neon Light Strips

Residential Interior Lighting

Accent and Ambient Lighting: Homeowners use cuttable RGB strips to create ambiance in living rooms, bedrooms, and kitchens. Installed under cabinets, behind TVs, or along ceiling coves, they add depth and warmth, with color-changing capabilities to match moods or activities—from calm blues for relaxation to vibrant hues for entertaining.

Custom Furniture Illumination: Cut to fit shelves, headboards, or entertainment centers, these strips transform furniture into focal points. Trimmed to precise dimensions, they highlight architectural details or illuminate display items without overwhelming the space.

Room Zoning and Decor: Open-concept spaces benefit from cuttable strips to define zones, such as dining areas or home offices. By cutting strips to fit specific boundaries, users create visual separation while maintaining a cohesive design.

Commercial and Retail Displays

Branded Visual Merchandising: Retailers use cuttable RGB strips to highlight products, create window displays, or reinforce brand identity. Strips are trimmed to fit display cases, shelving, or signage, with color programming that aligns with brand colors or seasonal promotions.

Hospitality and Restaurant Lighting: Hotels, cafes, and restaurants leverage these strips to enhance customer experiences. Installed along bar tops, booth edges, or outdoor patios, they create inviting atmospheres that adapt to different times of day—bright and energetic for daytime, warm and intimate for evenings.

Office and Workspace Design: Cuttable RGB strips support ergonomic lighting in offices, with installations under desks, along cubicle partitions, or in meeting rooms. Adjustable colors and brightness help reduce eye strain and boost productivity, with dynamic effects for collaborative spaces.

Architectural and Outdoor Applications

Exterior Building Accents: Cut to fit rooflines, columns, or facade details, weatherproof cuttable RGB strips enhance building exteriors after dark. They highlight architectural features, improve safety by illuminating pathways, and create visual interest for commercial or residential properties.

Event and Temporary Installations: Event planners use these strips for weddings, trade shows, or festivals, cutting them to fit stage backdrops, booth structures, or tent interiors. Their flexibility allows quick customization to match event themes, with easy installation and removal for temporary setups.

Artistic and Creative Projects: Artists and designers incorporate cuttable RGB strips into installations, murals, or interactive exhibits. Trimmed into shapes or patterns, they add dynamic lighting elements that respond to movement, sound, or user interaction, creating immersive experiences.

Troubleshooting and Maintenance for Cuttable RGB Neon Light Strips

Common Performance Issues

Flickering or Dim Segments: This often indicates loose connections or voltage drop in long runs. Check connectors for secure attachment, clean contact pads, and add power injection points if necessary to ensure consistent power distribution.

Color Inconsistencies: Mismatched colors between segments may result from poor connector alignment or controller settings. Ensure RGB channels are properly matched in connectors and recalibrate the controller to balance colors across the strip.

Adhesive Failure: If strips lift from surfaces, clean the area again to remove residue, reapply pressure, or use mounting clips for reinforcement. In humid environments, choose strips with weather-resistant adhesive or supplement with silicone sealant.

Routine Maintenance Practices

Regular Cleaning: Dust and debris can dull light output over time. Gently wipe strips with a soft, dry cloth or compressed air to maintain brightness, avoiding harsh chemicals that may damage the silicone housing.

Connection Inspections: Periodically check connectors for signs of corrosion or looseness, particularly in outdoor or damp installations. Clean contacts with isopropyl alcohol and resecure connections to prevent intermittent performance issues.

Controller Updates and Care: For smart controllers, keep firmware updated to ensure compatibility with new features or devices. Store remotes in dry locations and replace batteries regularly to maintain reliable operation.

Choosing the Right Cuttable RGB Neon Light Strips

Key Selection Criteria

Environmental Compatibility: Select strips with appropriate IP ratings for the installation location—IP20 for dry indoor spaces, IP65 for kitchens or covered outdoor areas, and IP68 for fully submerged or exposed outdoor use.

Color and Brightness Requirements: Consider color range (RGB vs. RGBW for white balance) and brightness levels based on application. Task lighting may require higher brightness, while ambient lighting benefits from softer, diffused output.

Controller Compatibility: Choose strips compatible with desired control methods—basic remotes for simplicity, app-enabled controllers for smart home integration, or DMX controllers for commercial-grade programmability.

Quality and Reliability Factors

Manufacturer Reputation: Opt for strips from reputable brands known for quality and durability, with positive reviews highlighting consistent performance and customer support.

Material and Construction: Look for strips with thick, UV-resistant silicone housing and copper contact pads for longevity. Reinforced substrates and high-quality LEDs ensure resistance to wear, bending, and temperature changes.

Warranty and Certifications: Select strips with warranties of 2–5 years, indicating manufacturer confidence in durability. Certifications like UL, CE, or RoHS confirm compliance with safety and environmental standards.

Future Trends in Cuttable RGB Neon Light Strip Technology

Enhanced Smart Integration: Upcoming strips will feature improved connectivity with IoT ecosystems, enabling seamless integration with sensors, voice assistants, and home automation systems for more intuitive control.

Advanced Material Science: Innovations in silicone formulations will enhance durability, flexibility, and light diffusion, while reducing environmental impact through recyclable or biodegradable materials.

Energy Efficiency Improvements: Next-generation LEDs will further reduce power consumption while increasing brightness and color range, making cuttable RGB strips even more sustainable for long-term use.

Conclusion: Cuttable RGB Neon Strips as a Versatile Lighting Solution

Cuttable RGB neon light strips have revolutionized customizable lighting, offering unparalleled flexibility to fit the unique demands of any space. Their ability to be trimmed to exact lengths, combined with vibrant color capabilities and durable construction, makes them indispensable for homeowners, designers, and businesses seeking tailored illumination.

From residential accents to commercial displays and architectural features, these strips deliver both functionality and creativity, adapting to diverse applications with ease. As technology advances, their performance, efficiency, and integration capabilities will continue to expand, solidifying their role as a versatile and essential tool in modern lighting design. Whether for a small home project or a large-scale installation, cuttable RGB neon light strips provide the precision and adaptability needed to bring lighting visions to life.