Time:2025-07-12

The Critical Need for Waterproof Neon Signage in Outdoor Hospitality

In the dynamic world of outdoor hospitality, waterproof custom neon bar signage has emerged as a indispensable solution for venues seeking to blend visual appeal with rugged durability. Outdoor bars, rooftop lounges, and beer gardens face constant exposure to rain, sunlight, wind, and temperature fluctuations, demanding signage that withstands the elements while delivering vibrant, consistent branding. Waterproof custom neon signage combines the iconic glow of traditional neon with advanced waterproofing technology, offering venue owners a reliable platform to enhance visibility, reinforce brand identity, and create inviting al fresco environments.

This article explores the technical innovations, design advantages, and strategic applications of waterproof custom neon bar signage, providing a comprehensive guide for hospitality professionals to leverage these systems for resilient and eye-catching outdoor displays.

Technical Foundations: Engineering for Outdoor Resilience

Core Components of Waterproof Neon Signage

Waterproof Encapsulation Technology

Waterproof neon signage is defined by its ability to resist moisture and environmental stress through specialized materials and construction:

Silicone Overmolding: High-grade silicone casings (typically 1–2mm thick) fully encapsulate LED neon flex, creating a seamless, watertight barrier. This material offers superior resistance to UV radiation, ozone, and temperature extremes (-50°C to 150°C), making it ideal for coastal, high-rainfall, or desert environments.

IP Rating Standards:

IP65: Protected against water jets and dust, suitable for outdoor signs exposed to splashes (e.g., patio umbrellas, covered decks).

IP67/IP68: Fully waterproof for submersion (IP68) or prolonged water exposure (IP67), essential for poolside bars, beachfront venues, or regions with heavy rainfall.

Corrosion-Resistant Electrical Components

Sealed Connectors: Gold-plated or nickel-coated connectors with O-ring seals prevent water ingress, paired with heat-shrink tubing for additional protection at connection points.

PCB Protection: Printed circuit boards (PCBs) coated with conformal sealants resist moisture and salt corrosion, critical for coastal pubs where air humidity and salt spray pose threats to electrical integrity.

Durable LED Neon Flex

High-Brightness LEDs: Surface-mounted LEDs with tight wavelength tolerances ensure vibrant color output even after years of outdoor exposure, with options for RGB, single-color, or RGBW (warm/cool white + color) configurations.

Flexible Substrate: Polyimide or fiberglass-reinforced PCBs allow the neon to bend to tight radii (15–30mm), adapting to curved signage, logos, or architectural features without compromising waterproofing.

Key Advantages of Waterproof Custom Neon for Outdoor Bars

Uncompromised Durability in Harsh Environments

Weather Resistance: Silicone-encased neon withstands 10+ years of UV exposure without yellowing or color fading, far outlasting traditional painted metal or plastic signage.

Impact Resilience: Flexible silicone absorbs minor impacts (e.g., accidental bumps from patio furniture or wind-blown debris), reducing the risk of cracks or LED damage.

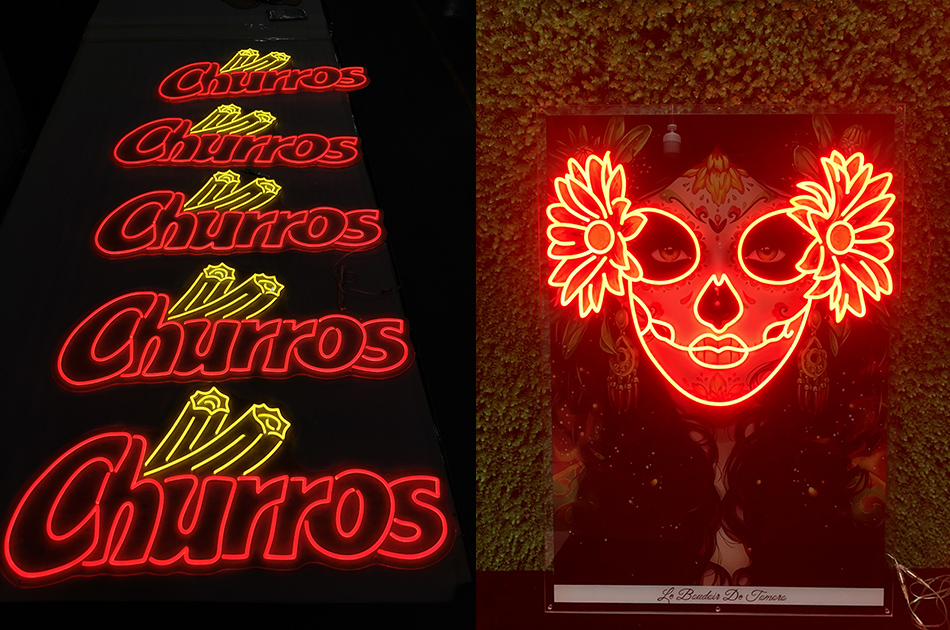

Design Flexibility for Brand Expression

Custom Shapes and Fonts: CNC-bending technology enables precise replication of logos, cursive text, or abstract designs, allowing venues to create unique outdoor brand identifiers that stand out in crowded urban landscapes.

Layered Visual Effects: Combine front-lit neon with back-lit acrylic panels for depth, or use translucent backings to create halo effects, all while maintaining full waterproof integrity.

Energy Efficiency and Safety

Low-Voltage Operation: Runs on 12V/24V DC, minimizing energy use and eliminating risks associated with high-voltage outdoor wiring.

Cool-to-Touch Operation: LED technology generates minimal heat, reducing fire hazards in outdoor settings with dry vegetation or flammable decor.

Low Maintenance and Longevity

Seamless Cleaning: Smooth silicone surfaces repel dust and water, requiring only occasional rinsing with mild soap—no special cleaning agents needed.

Modular Design: Replaceable neon segments allow easy repair of damaged sections without dismantling the entire sign, reducing maintenance downtime and costs.

Strategic Applications in Outdoor Hospitality

Patio and Rooftop Bars

Entrance Signage: Waterproof neon logos above patio entrances or rooftop access points, with IP67 ratings to withstand rain and wind, ensuring year-round brand visibility.

Bar Counter Accents: Neon strips along outdoor bartop edges or pergola beams, programmable to change colors for seasonal events (e.g., icy blue for winter rooftops, vibrant green for summer), all while resisting moisture from spills or rain.

Beachfront and Coastal Venues

Tiki Bar and Cabana Signs: Custom neon outlines of tropical motifs or drink names, encased in UV-stabilized silicone to combat saltwater corrosion and intense sunlight.

Poolside Branding: IP68-rated neon along pool edges or cabana roofs, safe for occasional submersion during pool cleaning or rainstorms, enhancing nighttime ambiance with vibrant, watertight illumination.

Beer Gardens and Courtyards

Pathway Markers: Colored neon strips along garden pathways or seating zone dividers, with motion sensors to activate lighting when guests approach, improving safety while resisting dew and morning moisture.

Menu and Event Displays: Backlit waterproof menus or event boards, ensuring readability in all weather conditions, with remote-controlled color changes to highlight daily specials or live music nights.

Seasonal Pop-Up Bars

Temporary Outdoor Installations: Lightweight, waterproof neon signs for pop-up events, easily transported and installed with adhesive mounts or portable frames, maintaining visual impact through rain or shine.

Holiday-Themed Displays: Reusable neon decorations for Christmas markets or summer festivals, stored and reused annually without degradation from outdoor storage.

Design and Installation Best Practices

Phase 1: Environmental Assessment and Design Brief

Location Analysis:

Exposure Level: Classify the sign’s environment (sheltered vs. fully exposed) to select appropriate IP ratings (IP65 for covered patios, IP67 for open-air beach bars).

Climate Considerations: Factor in UV intensity, average rainfall, and temperature ranges to choose silicone hardness (shore A 60–80 for flexibility in cold climates, shore A 80–90 for heat resistance).

Brand Integration:

Work with designers to translate brand guidelines into waterproof signage concepts, ensuring color accuracy and font legibility even when wet or under low-light conditions.

Phase 2: Material and Component Selection

Waterproofing Prioritization:

Outdoor Frames: Aluminum or stainless steel frames with powder-coat finishes to resist rust, paired with silicone gaskets for watertight sealing between the sign and mounting surface.

Connector Seals: Use IP68-rated connectors with locking collars for outdoor installations, ensuring no water penetrates electrical joints.

LED and Control Options:

Color Stability: Choose LEDs with ±2% wavelength tolerance to maintain brand color consistency under prolonged UV exposure.

Remote Control Systems: Waterproof-rated remote controls or Bluetooth modules (IP65) for outdoor use, allowing staff to adjust colors or brightness from under umbrellas or sheltered areas.

Phase 3: Installation Techniques

Mounting Solutions:

Wall-Mounted Signs: Use corrosion-resistant screws or rivets with waterproof washers, ensuring the sign is elevated 1–2cm from the wall to allow air circulation and water runoff.

Hanging Signs: Stainless steel cables or chains with rubber grommets to protect wiring from abrasion, ideal for overhead patio signs exposed to wind movement.

Electrical Safety:

Install GFCI (Ground Fault Circuit Interrupter) outlets for outdoor power connections, protecting against electrical faults caused by moisture.

Concel wiring within PVC conduits or waterproof cable trays, routing them away from direct water streams (e.g., roof gutters, downspouts).

Phase 4: Maintenance and Testing

Post-Installation Checks:

Water Spray Test: Simulate heavy rain with a garden hose to check for water ingress at connectors and mounting points.

UV Resistance Test: Use a UV intensity meter to ensure the sign’s color stability after 1,000+ hours of exposure, replacing any fading segments promptly.

Routine Care:

Monthly Inspections: Check connector seals for cracks or debris, and tighten mounting hardware to resist wind-induced vibrations.

Annual Deep Clean: Use a soft brush and mild detergent to remove accumulated grime, avoiding abrasive tools that could scratch the silicone surface.

Key Considerations When Selecting Waterproof Neon Signage

Waterproof Rating Matching

IP65: Suitable for signs under awnings or umbrellas, protecting against splashes and dust.

IP67: Ideal for fully exposed outdoor areas, resisting temporary submersion (e.g., during heavy rain or pressure washing).

IP68: Necessary for signs in high-risk zones like pool areas or coastal locations with frequent wave splashes.

Material Durability

Silicone Quality: Opt for FDA-grade or outdoor-rated silicone to ensure no yellowing or brittleness over time, with a minimum thickness of 1.5mm for impact resistance.

Frame Materials: Aluminum for lightweight durability, stainless steel for coastal salt resistance, and powder coating for additional weather protection.

Certification and Compliance

Safety Standards: Ensure signs meet UL 1598 (Outdoor Sign Lighting) and CE EN 60598-2-22 for waterproof luminaires, critical for insurance compliance and customer safety.

Environmental Compliance: RoHS-compliant materials to avoid hazardous substances, important for venues pursuing green certifications or operating in eco-sensitive areas.

Supplier Expertise

Outdoor Project Portfolio: Partner with suppliers who have experience in coastal, high-rainfall, or extreme climate installations, capable of providing case studies and material testing data.

Custom Fabrication Skills: Suppliers offering in-house CNC bending, waterproof connector assembly, and UV aging testing ensure precision in complex outdoor designs.

Innovations in Waterproof Neon Signage Technology

Smart Waterproof Control Systems

Weather-Responsive Dimming: Sensors that auto-adjust brightness during rain or low visibility, ensuring the sign remains visible without excessive energy use.

Remote Monitoring Apps: Cloud-based platforms to track waterproof sign performance, receiving alerts for connector leaks or UV degradation in real time.

Sustainable Waterproof Materials

Recycled Silicone Casings: Emerging products using 50% post-industrial recycled silicone, combining waterproof performance with environmental responsibility.

Bio-Based Sealants: Plant-derived waterproof adhesives that reduce VOC emissions, ideal for eco-conscious outdoor venues.

Advanced Design Tools

3D Waterproof Modeling: Software that simulates water flow and UV exposure on custom sign designs, optimizing waterproofing for complex shapes like curved logos or multi-layered signage.

AR Prototyping: Augmented reality apps allowing venue owners to visualize waterproof signs in their outdoor space before fabrication, ensuring design and functionality alignment.

Overcoming Common Outdoor Signage Challenges

Challenge 1: Mold and Algae Growth

Solution: Choose silicone with anti-microbial additives and install signs at a 15° angle to promote water runoff, reducing moisture retention on the surface.

Challenge 2: UV-Induced Color Fading

Solution: Specify LEDs with a UV protection factor (UPF) of 50+ and apply a clear, UV-stabilized topcoat on silicone surfaces, extending color longevity by 30%.

Challenge 3: Wind Load on Large Signs

Solution: Use aerodynamic frame designs and calculate wind load ratings (e.g., 150 km/h for coastal areas), reinforcing mounting points with structural adhesives and mechanical fasteners.

Challenge 4: Condensation Inside Enclosed Signs

Solution: Install breathable waterproof membranes or desiccant packets inside sign frames to absorb moisture, preventing fogging on internal surfaces.

Conclusion: Waterproof Neon as an Outdoor Hospitality Essential

Waterproof custom neon bar signage has evolved into a vital asset for outdoor hospitality venues, offering a perfect balance of durability, design flexibility, and visual impact. By leveraging advanced waterproofing technology, durable materials, and smart design practices, these signs withstand the harshest outdoor conditions while delivering vibrant, consistent branding that attracts guests and enhances the al fresco experience.

As the demand for outdoor dining and social spaces continues to grow, waterproof neon signage stands out for its ability to transform exposed environments into inviting, weather-resistant destinations. Venue owners who prioritize high-quality, certified systems and collaborate with experienced suppliers can ensure their outdoor signage not only survives but thrives—proving that in the face of nature’s challenges, style and resilience can coexist seamlessly.v