Time:2025-06-21

In an era where environmental consciousness is at the forefront of business decisions, the demand for eco-friendly lighting solutions has surged. Silicone neon strips, with their versatility and aesthetic appeal, have become a popular choice for various applications. However, when seeking to incorporate these strips into projects, partnering with eco-friendly silicone neon strip production partners is not just a preference but a necessity. This article delves into the significance of such partnerships, the key aspects of eco-friendly production, and how to identify and collaborate with the right partners in this domain.

The Rising Tide of Environmental Awareness in the Lighting Sector

The Call for Sustainable Lighting

As environmental concerns intensify globally, consumers and businesses alike are demanding more sustainable lighting options. Silicone neon strips, which have long been favored for their flexibility, energy - efficient illumination, and decorative qualities, are now under scrutiny regarding their environmental impact. Traditional manufacturing processes often involve the use of non - renewable resources, harmful chemicals, and significant energy consumption. In contrast, eco-friendly production partners are pioneering new ways to produce these strips with a reduced carbon footprint. This shift is not only driven by consumer demand but also by the realization that sustainable practices are essential for the long - term health of the planet and the lighting industry.

Regulatory Pressures and Incentives

Governments around the world are implementing increasingly strict regulations to combat climate change and promote sustainable manufacturing. For the silicone neon strip industry, these regulations cover a wide range of aspects, from the use of hazardous substances in production to energy - efficiency standards for the final products. Eco-friendly production partners are acutely aware of these regulations and invest in research, development, and infrastructure to ensure full compliance. They often benefit from government incentives, such as tax breaks or grants, for adopting sustainable practices. This not only helps them stay ahead in a competitive market but also provides assurance to their clients that the products they supply are in line with the latest environmental requirements.

Hallmarks of Eco-friendly Silicone Neon Strip Production

Sustainable Material Selection

The journey towards eco-friendly production begins with material sourcing. High - quality, recycled silicone is a key component in eco-friendly neon strips. By using recycled silicone, manufacturers can significantly reduce the demand for virgin materials, which in turn conserves natural resources and reduces energy consumption associated with the extraction and processing of new silicone. Additionally, the LED chips integrated into these strips are sourced from suppliers committed to ethical and sustainable practices. These LEDs are designed to be highly energy - efficient, consuming less power while delivering bright and long - lasting illumination. The circuit boards and other supporting materials are also carefully chosen, with an emphasis on recycled or recyclable options, further minimizing the environmental impact of production.

Energy - Conservation in Manufacturing

Eco-friendly production partners are at the forefront of implementing energy - saving technologies in their manufacturing processes. Advanced manufacturing machinery is employed, which is engineered to consume less electricity during operation. Production line layouts are optimized to eliminate unnecessary energy waste, such as reducing the distance materials need to travel during the assembly process. Smart energy management systems are installed, allowing manufacturers to monitor and control energy usage in real - time. Some forward - thinking producers even harness renewable energy sources, like solar or wind power, to run their production facilities. By reducing energy consumption, these manufacturers not only contribute to environmental sustainability but also lower their operational costs, making their products more cost - competitive in the market.

Waste Minimization and Recycling Initiatives

Waste reduction and recycling are integral parts of eco-friendly silicone neon strip production. During the manufacturing process, every effort is made to minimize waste generation. Precision - cutting techniques are used to reduce offcuts of silicone, and quality control measures are tightened to minimize the production of defective components. When waste is inevitably produced, it is carefully sorted and recycled or repurposed. Many production partners have established in - house recycling programs, where materials like silicone scraps and old circuit boards are processed and transformed into new raw materials for use in future production. This circular approach to waste management not only reduces the amount of waste sent to landfills but also closes the loop in the production cycle, creating a more sustainable and resource - efficient business model.

The Perks of Collaborating with Green - Minded Producers

Elevating Brand Image

For companies aiming to enhance their environmental reputation, partnering with eco-friendly silicone neon strip producers is a strategic move. By associating with producers committed to sustainable practices, businesses can position themselves as environmentally responsible in the eyes of consumers. This can lead to increased brand loyalty, as consumers are more likely to support companies that share their values. For example, a hotel that uses eco-friendly silicone neon strips for its interior lighting can promote this as part of its green initiatives, attracting environmentally conscious guests. Positive word - of - mouth marketing also follows, as satisfied customers are more likely to recommend a brand that is seen as eco - friendly, giving the company a competitive edge in the market.

Long - Term Cost - Savings

While the initial investment in eco-friendly silicone neon strips may seem slightly higher in some cases, the long - term benefits far outweigh the upfront costs. Energy - efficient strips consume less power, resulting in lower electricity bills over time. The use of high - quality, sustainable materials also contributes to a longer product lifespan, reducing the need for frequent replacements. This not only saves money on purchasing new strips but also on the associated costs of installation and maintenance. Moreover, as environmental regulations become more stringent, companies that already source from eco-friendly partners are better positioned to avoid potential fines and compliance - related costs, ensuring a more stable and cost - effective supply chain.

Gaining Access to Innovation

Eco-friendly production partners are often at the vanguard of innovation in the lighting industry. They invest substantial resources in research and development to create new and improved products that are both more sustainable and offer enhanced performance. By collaborating with these partners, businesses gain access to cutting - edge technologies and solutions. For instance, some producers are developing silicone neon strips with advanced color - changing capabilities that can be controlled via mobile apps, or strips that are more resistant to harsh environmental conditions. These innovative products can open up new opportunities for businesses to differentiate themselves in the market and meet the evolving needs of their customers.

Key Considerations When Picking an Eco-friendly Partner

Certification and Compliance Verification

When evaluating potential production partners, verifying their certifications and compliance is of utmost importance. Look for partners with certifications such as ISO 14001, which indicates a robust environmental management system. Additionally, certifications related to specific sustainable claims, like the use of recycled materials or energy - efficiency achievements, should be examined. Request detailed documentation and references to confirm these claims. It's also crucial to ensure that the partner complies with all local, national, and international environmental regulations. This includes regulations regarding the disposal of waste, the use of hazardous substances, and energy - efficiency standards. A partner that can demonstrate a strong commitment to compliance is more likely to produce high - quality, eco - friendly products.

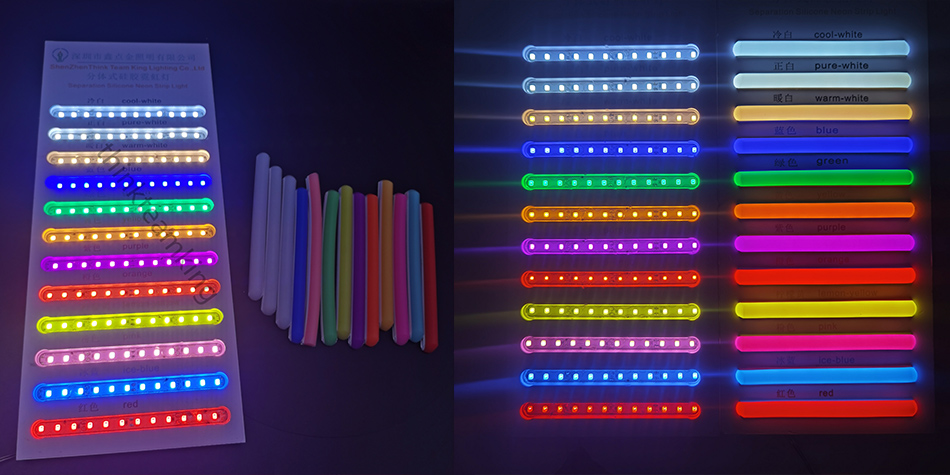

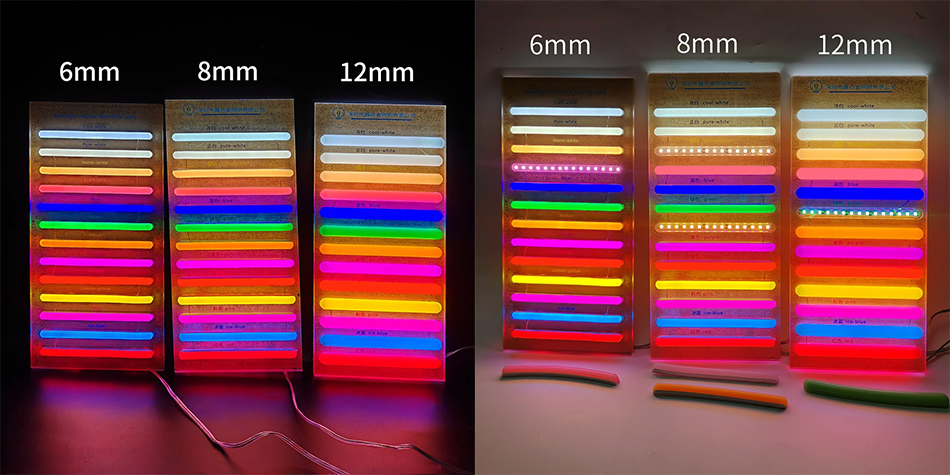

Product Portfolio and Customization Capabilities

A diverse product portfolio is a sign of a versatile production partner. The ideal partner should offer a wide range of silicone neon strips, including different colors, styles, and lighting effects. This allows businesses to meet the varied needs of their customers, whether it's for a modern office interior, a trendy retail store, or a unique event decoration. In addition to a broad product range, customization capabilities are highly valuable. The ability to create bespoke neon strips, such as those with custom shapes, sizes, or integrated control systems, can give a business a competitive advantage. Whether it's designing a neon strip in the shape of a company logo for a storefront or creating a special - effect strip for a themed event, a partner that can accommodate customization requests is more likely to be a valuable long - term collaborator.

Reputation and Track Record

Researching the reputation of a production partner is essential. Look for customer reviews, testimonials, and case studies, both online and through industry networks. A partner with a positive reputation is more likely to deliver high - quality products and excellent service. Check for any past issues related to environmental practices or product quality and how the partner addressed them. A good track record of timely deliveries, responsive customer service, and continuous improvement in sustainability efforts is a strong indicator of a reliable partner. For example, if a partner has successfully worked on large - scale projects with well - known brands and received positive feedback, it gives confidence in their ability to handle similar projects in the future.

The Intricate Process of Manufacturing Eco-friendly Silicone Neon Strips

Material Procurement and Preparation

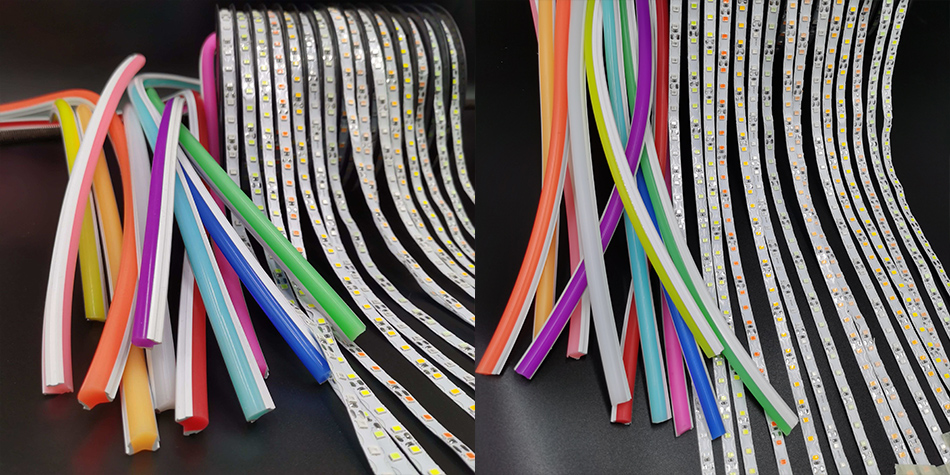

The manufacturing process commences with meticulous material procurement. Sustainable silicone is sourced from reliable suppliers who adhere to strict environmental and quality standards. Recycled silicone, if used, undergoes a thorough cleaning and purification process to ensure it meets the required quality for neon strip production. LED chips are carefully selected and pre - tested to guarantee their performance and energy - efficiency. The circuit boards and other components are also sourced from suppliers with a commitment to sustainability. Once the materials are procured, they are prepared for assembly. The silicone is often extruded into the desired shape, whether it's a straight strip or a more complex profile, while the LED chips are mounted onto the pre - prepared circuit boards using precise soldering techniques.

Assembly and Encapsulation

The assembly stage involves integrating the LED - equipped circuit boards into the silicone casing. This process requires precision to ensure proper alignment and electrical connections. The LED - circuit board assemblies are carefully inserted into the silicone casing, and the ends are sealed to protect the internal components from moisture and other environmental factors. Some producers use advanced encapsulation techniques, such as injecting a special silicone compound around the LED - circuit board assembly, which not only provides additional protection but also enhances the strip's durability and heat - dissipation capabilities. The assembled strips are then subjected to initial quality checks to ensure that the electrical connections are secure and the lighting functions as expected.

Rigorous Quality Control and Testing

Quality control is a critical aspect of the manufacturing process. Each silicone neon strip undergoes multiple tests to meet both environmental and performance standards. Electrical tests are conducted to verify proper voltage operation, current consumption, and insulation resistance. Optical tests are performed to measure the brightness, color accuracy, and color - rendering index of the LEDs. The silicone casing is tested for its physical properties, including flexibility, tensile strength, and resistance to UV rays and temperature variations. In addition, the strips are tested for compliance with relevant environmental regulations, such as restrictions on hazardous substances. Only after passing all these tests are the neon strips approved for packaging and distribution.

Building and Nurturing a Productive Partnership

Establishing Open Communication Channels

Open and clear communication is the foundation of a successful partnership. From the initial stages of discussing product requirements to the ongoing management of orders, maintaining regular communication with the production partner is crucial. Clearly communicate your specific needs, such as the quantity of neon strips required, any customization details, and your expected delivery schedule. A responsive partner will be able to provide prompt answers to your questions, offer expert advice based on their experience, and keep you informed of any potential issues or delays. Regular communication can help prevent misunderstandings and ensure that the production process runs smoothly.

Order Placement and Payment Arrangements

Once you have finalized the product details, the next step is to place your order. Familiarize yourself with the partner's order - placement process and payment terms. Some partners may require a deposit upfront, while others may offer more flexible payment options, such as payment upon delivery or installment plans. Ensure that the payment terms are fair and secure for both parties. It's also important to clarify any issues related to order changes, cancellations, or returns at this stage. A well - defined order - placement and payment process can help streamline the business relationship and avoid potential disputes in the future.

Post - Sales Support and Service

A reliable production partner should offer comprehensive post - sales support. This includes a clear warranty policy, a process for handling product returns or exchanges in case of defects, and technical support for any installation or operational issues. Inquire about the partner's response time to customer inquiries and their willingness to provide on - site support if needed. Good post - sales support not only ensures customer satisfaction but also reflects the partner's confidence in the quality of their products. A partner that stands behind their products and provides ongoing support is more likely to build long - term relationships with its customers.

The Horizon: Future Trends for Eco-friendly Silicone Neon Strip Production Partners

Technological Innovations on the Horizon

The future of eco-friendly silicone neon strip production is likely to be shaped by continued technological advancements. Producers may integrate more advanced smart lighting technologies, such as near - field communication (NFC) or 5G connectivity, into their strips. This would enable features like remote control, real - time monitoring, and integration with building management systems. Additionally, research into new materials and manufacturing techniques may lead to even more sustainable and efficient products. For example, the development of biodegradable or more highly recyclable silicone materials could further reduce the environmental impact of neon strip production.

Expanding Market Horizons

As environmental awareness continues to grow globally, the market for eco-friendly silicone neon strips is expected to expand. In emerging economies, where infrastructure development and urbanization are on the rise, there will be an increasing demand for sustainable lighting solutions. These regions present significant opportunities for production partners to enter new markets and establish themselves as leaders in eco-friendly lighting. Moreover, as more industries, such as healthcare, education, and hospitality, prioritize sustainability, the demand for eco-friendly neon strips in these sectors is likely to surge, opening up new avenues for growth and collaboration.sAdapting to Stringent Regulatory Changes

Regulatory requirements for the lighting industry are expected to become even more stringent in the coming years. Eco-friendly production partners will need to stay ahead of these changes by continuously investing in research and development to ensure their products remain compliant. This may involve adopting new manufacturing processes, using more sustainable materials, or improving energy - efficiency even further. Partners that can proactively adapt to regulatory changes will not only avoid potential legal issues but also gain a competitive edge in the market, as they will be better positioned to meet the evolving needs of customers and regulatory bodies alike.

In conclusion, partnering with eco-friendly silicone neon strip production partners is a strategic choice that offers numerous benefits for businesses in the lighting industry. By understanding the key aspects of eco-friendly production, carefully evaluating potential partners, and building strong relationships, companies can contribute to environmental sustainability while also achieving their business goals. The future holds great promise for the eco-friendly silicone neon strip market, and those who embrace these trends and opportunities are likely to thrive in this dynamic industry.