Time:2025-07-10

The Revolution of Flexible Neon Strips in Modern Lighting

In an age where design demands both creativity and functionality, flexible neon strips have emerged as a transformative solution, blending the iconic allure of traditional neon with unprecedented adaptability. These innovative lighting systems transcend the limitations of rigid fixtures, offering seamless integration into curved, angular, or irregular surfaces while delivering vibrant, consistent illumination. Whether enhancing residential interiors, elevating commercial branding, or adding safety to industrial spaces, flexible neon strips have become a cornerstone of contemporary lighting design.

This article explores the technical prowess, design versatility, and diverse applications of flexible neon strips, providing a comprehensive guide for professionals and enthusiasts seeking to leverage their unique capabilities. From material innovations to smart integrations, discover how these strips are reshaping the landscape of illuminated environments.

Technical Foundations: The Science of Flexibility and Performance

Engineered for Movement and Precision

Flexible Substrate Technology

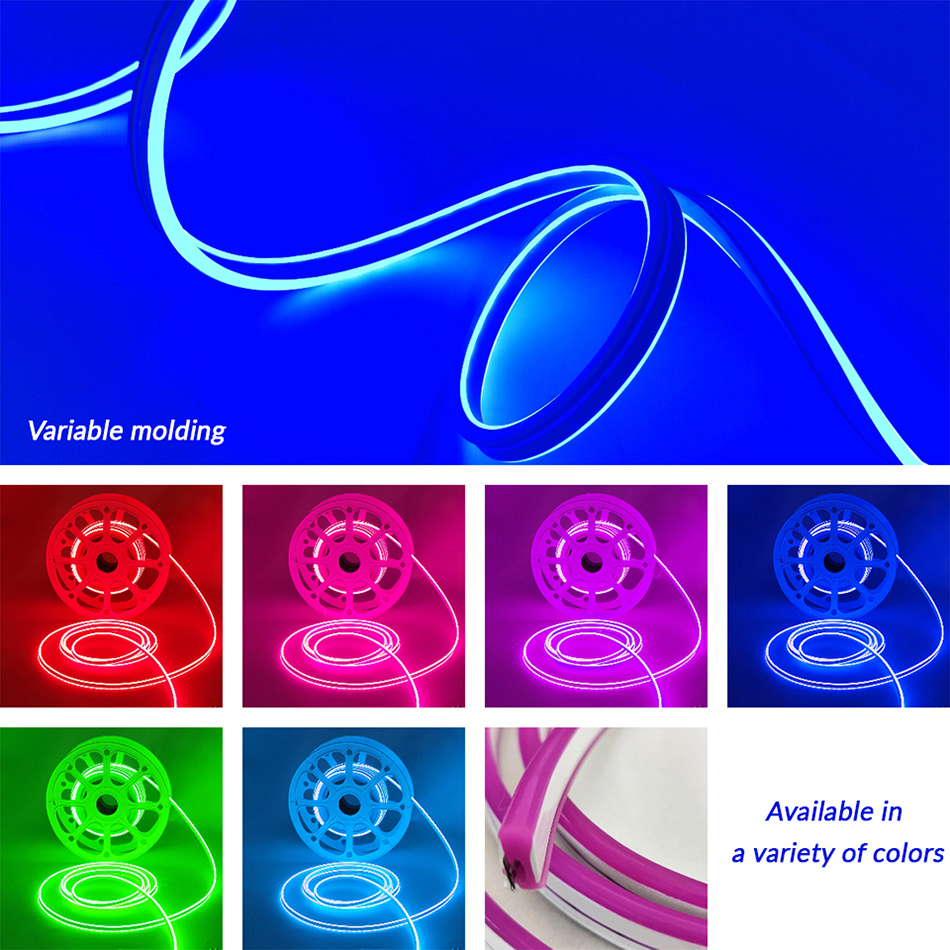

At the core of flexible neon strips is a bendable printed circuit board (PCB) or composite material that allows the strip to conform to virtually any shape. This substrate, often reinforced with fiberglass or polyimide, supports tight-radius bending (as low as 10mm in premium models) without compromising electrical conductivity or LED performance. The result is a seamless transition around curves, corners, and complex contours, enabling designers to translate architectural visions into illuminated reality.

Durable Encapsulation for Longevity

Most flexible neon strips feature an outer casing of silicone, PVC, or TPE (thermoplastic elastomer), chosen for its balance of flexibility and durability:

Silicone: Offers superior resistance to UV radiation, temperature extremes (-40°C to 80°C), and physical impacts, making it ideal for outdoor or high-movement environments.

PVC: A cost-effective option with moderate flexibility, suitable for indoor applications where weather resistance is less critical.

TPE: Combines the best of both worlds, providing high elasticity and chemical resistance for demanding industrial settings.

LED Technology: The Heart of Efficient Illumination

Modern flexible neon strips rely on surface-mounted LED chips to deliver energy-efficient, vibrant light:

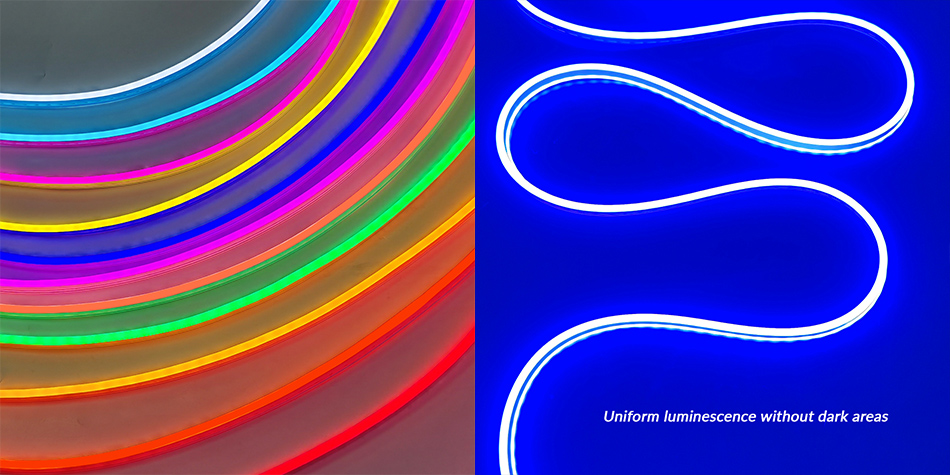

Uniform Light Distribution: Dense LED placement (typically 30–60 units per meter) ensures consistent brightness across the strip, even when bent or curved.

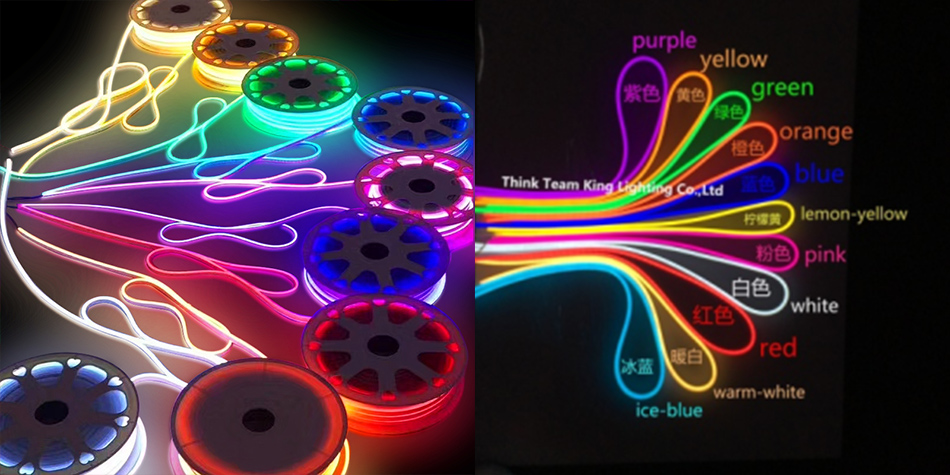

Color Versatility: RGB (Red-Green-Blue) and RGBW (with white channel) variants enable millions of color combinations, while single-color options offer pure, saturated hues for brand-specific applications.

Low Heat Emission: LEDs generate minimal thermal output, reducing fire risks and allowing safe installation near textiles, plastics, or decorative materials.

Low-Voltage Safety and System Integration

Operating at 12V or 24V DC, flexible neon strips prioritize safety and ease of use:

Plug-and-Play Compatibility: Works with standard power adapters, batteries, or solar panels, eliminating the need for high-voltage wiring and making them suitable for off-grid installations.

Polarity-Protected Connectors: Keyed interfaces prevent incorrect wiring, while advanced models feature built-in circuit protection to safeguard against short circuits or voltage fluctuations.

Diverse Types of Flexible Neon Strips

LED Neon Flex: The Epitome of Modern Flexibility

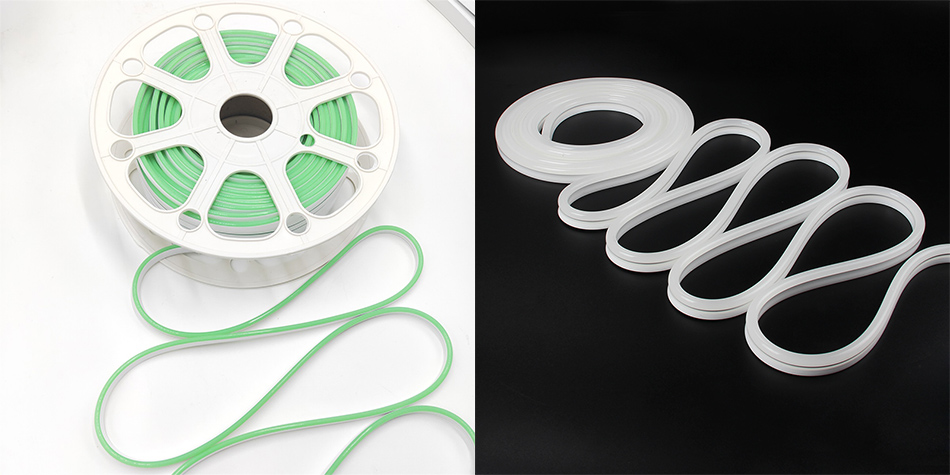

Construction: Ultra-flexible strips with LEDs embedded in a translucent silicone or PVC sheath, mimicking the soft, diffused glow of traditional neon.

Key Features:

Extreme Bendability: Adapts to complex shapes, from circular signage to undulating wall patterns.

Weather Resistance: IP65/IP67 ratings for outdoor use, with sealed connectors to prevent water ingress.

Ideal For: Retail window displays, architectural facades, and outdoor landscape lighting where durability and design freedom are essential.

Traditional Glass Neon (Flexible Variants)

Construction: Hand-bent glass tubes filled with neon or argon gas, engineered with flexible mounting systems for curved installations.

Key Features:

Authentic Neon Aura: Emits the warm, vintage glow associated with classic neon signs, perfect for retro-themed venues.

Indoor Excellence: Requires protective enclosures for outdoor use, but shines in controlled environments like art galleries or boutique stores.

Considerations: Fragile compared to LED variants; suitable for low-movement, high-aesthetic applications.

Miniature Flexible Neon Strips

Construction: Slim profiles (5–10mm width) with micro-LEDs on ultra-flexible PCBs, designed for intricate or space-constrained projects.

Key Features:

Precision Bending: Conforms to tight spaces like jewelry boxes, model railways, or under-cabinet lighting.

Lightweight Design: Easily mounted with minimal adhesive, ideal for delicate crafts or temporary installations.

Ideal For: Small-scale decor, DIY projects, and detailed interior design elements.

Smart Flexible Neon Strips

Construction: Integrates Bluetooth/Wi-Fi controllers or sensors into the strip for automated lighting effects.

Key Features:

Dynamic Control: Adjust colors, brightness, and patterns via smartphone apps or voice assistants (e.g., Alexa, Google Assistant).

Sensor Integration: Motion-activated dimming or color changes, enhancing energy efficiency and user experience.

Ideal For: Smart homes, hospitality venues, and commercial spaces requiring adaptive lighting solutions.

Design Advantages: Where Flexibility Meets Creativity

Unrestricted Design Freedom

Contour Conformity: Wraps seamlessly around columns, arches, and furniture, transforming structural elements into illuminated focal points.

Modular Layouts: Connect multiple strips to create large-scale patterns or segmented displays, with connectors designed to maintain visual continuity.

Effortless Installation for All Skill Levels

Adhesive Backing: Most strips feature strong 3M tape for quick mounting on smooth surfaces, with optional clips/brackets for textured or heavy-duty applications.

Tool-Free Assembly: No soldering required; plug-and-play connectors enable rapid setup, appealing to DIY enthusiasts and professionals alike.

Energy Efficiency and Sustainability

Low Power Consumption: Consumes 80% less energy than traditional neon, aligning with global sustainability goals.

Long Lifespan: LED variants operate for 50,000+ hours, reducing replacement waste and maintenance costs.

Safety and Reliability

Child and Pet Safe: Low voltage and cool operation eliminate risks associated with high-temperature fixtures.

Vibration Resistance: Silicone-encased strips withstand daily movement, making them suitable for vehicle interiors or industrial machinery.

Applications Across Industries and Spaces

Residential: Personalized Ambiance with Professional Flair

Interior Design

Architectural Accents: Highlight crown moldings, tray ceilings, or fireplace surrounds with flexible neon, creating subtle ambient light.

Functional Lighting: Under-cabinet illumination in kitchens, backlighting for mirrors in bathrooms, or shelf edge lighting for home offices—all customizable to fit unique layouts.

Bedroom Retreats: Wrap strips around headboards or canopy frames for soft, adjustable mood lighting, controlled via dimmers or smart systems.

Outdoor Living

Garden Elegance: Line pathways, tree trunks, or patio planters with weatherproof strips, enhancing safety and aesthetics.

Poolside Glamour: Waterproof neon along pool edges or cabana roofs, creating a luxurious nighttime atmosphere.

Commercial: Elevating Branding and Experience

Retail and Signage

Storefront Appeal: Craft custom logos or window displays with bendable neon, adapting to any font or shape for unforgettable first impressions.

In-Store Guidance: Use colored strips to highlight product zones or aisle markers, guiding customers seamlessly through retail spaces.

Hospitality and Events

Restaurant Ambiance: Define bar counters, booths, or menu boards with flexible neon, adjusting colors to match daytime casual or evening elegance.

Event Installations: Create temporary backdrops, photo booth frames, or stage designs that can be reconfigured for each occasion.

Hotels and Resorts

Luxury Interiors: Illuminate elevator interiors, spa relaxation zones, or suite balconies with curved neon, adding a touch of opulence.

Exterior Landmarks: Outline building facades or pool cabanas, enhancing nighttime visibility and guest experience.

Industrial and Functional: Safety Meets Efficiency

Workplace Safety

Machine Illumination: Highlight control panels, conveyor belts, or safety barriers in factories, improving visibility and reducing accidents.

Warehouse Aisles: Install low-voltage strips along rack edges for energy-efficient navigation, easily adjusted as storage layouts change.

Transportation and Marine

Vehicle Interiors: Customize car dashboards, RV cabinets, or aircraft galleys with flexible neon, conforming to curved surfaces in tight spaces.

Marine Applications: Waterproof strips on boat decks or cabins, enhancing navigation safety and onboard ambiance.

Installation Best Practices: From Planning to Execution

Phase 1: Design and Measurement

Space Analysis: Use 3D modeling or graph paper to map the installation area, noting curves, angles, and power source locations.

Material Selection: Choose strip type (LED for outdoor, glass neon for vintage look) and connector style (waterproof for wet areas, snap-fit for easy adjustments).

Phase 2: Preparation and Cutting

Locate Bend Points: Identify natural curves or corners in the space to determine optimal strip placement.

Gentle Handling: For glass neon, use specialized bending tools to avoid cracking; LED strips can be shaped by hand, following the substrate’s flexibility.

Phase 3: Mounting and Connectivity

Adhesive Application: Clean surfaces with isopropyl alcohol before applying strips, pressing firmly to ensure adhesive bonds evenly.

Mechanical Reinforcement: Use clips or brackets every 15–20cm for heavy strips or outdoor installations, especially at stress points like sharp bends.

Phase 4: Power and Control Integration

Power Supply Placement: Position adapters or batteries centrally to minimize voltage drop, using 22AWG cables for runs over 5 meters.

Smart Controls: Integrate dimmers, motion sensors, or app-based systems during installation for future flexibility.

Phase 5: Testing and Finishing

Function Check: Power on the system to verify uniform illumination and secure connections, adjusting connectors if needed.

Cable Management: Conceal wires with conduit or trim for a clean look, especially in visible areas.

Choosing the Right Flexible Neon Strips: A Buyer’s Guide

Application-Specific Features

Environmental Factors:

Indoor: Prioritize slim profiles and adhesive-backed strips for easy installation on drywall, wood, or glass.

Outdoor: Select IP65/IP67-rated strips with UV-resistant coatings and sealed connectors for rain, snow, or direct sunlight.

Design Complexity: For intricate curves (e.g., circular signage), opt for strips with a minimum bend radius that matches your project’s tightest angle.

Lighting Performance Criteria

Brightness Needs: Higher LED density (e.g., 60 LEDs/m) for intense task lighting; lower density (30 LEDs/m) for ambient or backlighting.

Color Technology: RGB for dynamic effects, single-color for brand consistency, and RGBW for warm/cool white adjustments.

Certification and Compliance

Safety Standards: Look for CE, UL, or IEC certifications to ensure electrical safety, especially for commercial use.

Environmental Compliance: RoHS-compliant strips are free of lead and mercury, essential for indoor installations in schools, offices, or homes.

Supplier and Product Quality

Durability Testing: Reputable suppliers provide bend-cycle ratings (e.g., 10,000+ cycles) and UV resistance data for outdoor strips.

Customer Support: Choose vendors offering detailed installation guides, warranty coverage (typically 2–5 years), and responsive technical assistance.

Overcoming Installation Challenges

Challenge 1: Maintaining Uniform Light Output on Sharp Bends

Root Cause: LED misalignment or substrate stress during bending.

Solution: Pre-bend strips to the desired radius using a template, ensuring LEDs face outward for consistent illumination.

Challenge 2: Adhesive Failure on Textured Surfaces

Root Cause: Low-tack adhesive or inadequate surface preparation.

Solution: Use dual-lock mounting tape or mechanical brackets for rough surfaces like brick or concrete, enhancing grip without damaging the strip.

Challenge 3: Voltage Drop in Long Runs

Root Cause: Undersized wiring or insufficient power supply capacity.

Solution: Use thicker gauge wires (22AWG or lower) and add a power booster for runs exceeding 10 meters, ensuring consistent voltage across the strip.

Challenge 4: Weather Damage on Outdoor Strips

Root Cause: Inadequate waterproofing or UV exposure.

Solution: Select strips with IP67 ratings and apply a protective silicone coating over connectors, especially in coastal or high-humidity areas.

Innovations Shaping the Future of Flexible Neon Strips

Smart and Sustainable Integrations

AI-Powered Lighting: Systems that auto-adjust colors based on ambient light or occupancy, optimizing energy use and user comfort.

Eco-Friendly Materials: Strips made with recycled silicone and energy-efficient LEDs, reducing carbon footprints without compromising performance.

Advanced Manufacturing Techniques

Laser-Precision Bending: Automated machines create complex curves with micron-level accuracy, ideal for large-scale architectural projects.

3D-Printed Accessories: Customizable mounting solutions that conform to unique geometries, eliminating the need for generic brackets.

Hybrid Lighting Systems

Neon-LED Combinations: Blending traditional neon’s warmth with LED’s efficiency in hybrid strips, offering the best of both worlds for high-end installations.

Projection-Mapping Integration: Flexible neon as a base for dynamic light projections, creating immersive visual experiences in entertainment venues.

Conclusion: The Endless Possibilities of Flexible Illumination

Flexible neon strips have transcended mere lighting fixtures to become tools of artistic expression and functional design. Their ability to adapt to any space, coupled with energy efficiency and safety, makes them indispensable across residential, commercial, and industrial sectors. As technology evolves—bringing smarter controls, sustainable materials, and precision manufacturing—these strips will only become more integral to creating environments that are both visually stunning and inherently practical.

Whether you’re a designer crafting a landmark installation, a business owner enhancing brand visibility, or a homeowner seeking to personalize your space, flexible neon strips offer a canvas for innovation. By leveraging their technical excellence and design versatility, you can transform ordinary surfaces into extraordinary illuminated experiences, proving that light itself can be as flexible and dynamic as the world it illuminates.