Time:2025-08-25

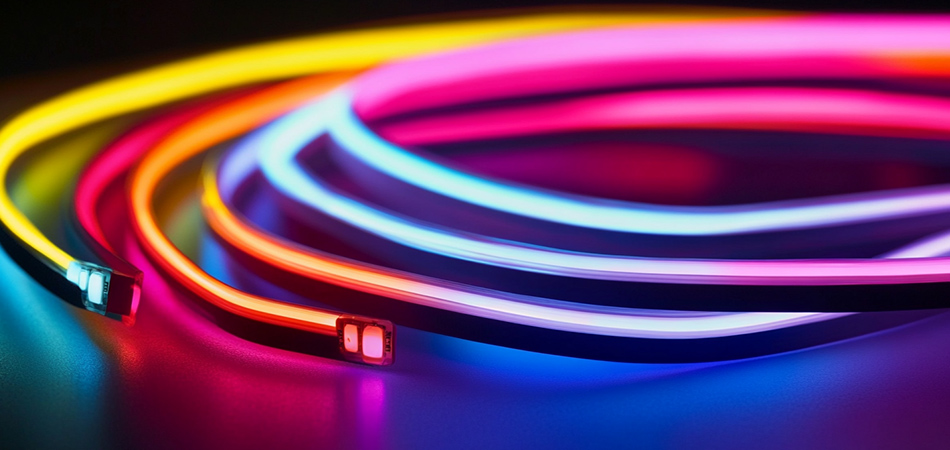

Cuttable neon flex strip rolls redefine flexibility in lighting, combining the adaptability of neon flex with the convenience of roll-form packaging—allowing users to cut precise lengths for any project, from small accent lighting to large-scale installations. Unlike pre-cut neon strips (which limit size options) or rigid neon tubes (which cannot be adjusted), these rolls offer a “measure-as-you-go” solution, eliminating waste and ensuring a perfect fit for irregular or unique spaces. Whether trimming a few inches for a bathroom mirror or unrolling dozens of feet for a commercial facade, cuttable neon flex strip rolls put control directly in the hands of designers, DIY enthusiasts, and professionals. This article explores their roll-specific design, safe cutting technology, installation efficiency, application versatility, and cost-saving benefits, highlighting why they have become a staple for projects requiring tailored illumination.

Cuttable neon flex strip rolls are engineered with roll-specific features that prioritize ease of use, storage, and precise cutting—setting them apart from other neon lighting formats. Continuous roll construction means the neon flex strip is manufactured as a single, unbroken length (wound onto a spool or core), rather than pre-cut segments. This allows users to unroll only what they need, minimizing waste and ensuring compatibility with projects of any size—from a 1-foot under-cabinet installation to a 50-foot building perimeter. The rolls are typically lightweight and compact, making them easy to transport, store, or ship, even for large-scale commercial orders.

Pre-marked cutting intervals are printed along the strip at regular, safe intervals, clearly indicating where cuts can be made without damaging internal components. These marks align with gaps between LED segments and circuitry, ensuring that cutting at these points leaves the remaining strip fully functional—no flickering, dimming, or loss of color consistency. The intervals are standardized across most rolls, simplifying measurement and reducing the risk of error, even for users with limited experience.

Protective packaging preserves the strip’s integrity during storage and handling. The roll is wrapped in a moisture-resistant film (often polyethylene) that shields the neon flex from dust, scratches, or minor impacts—critical for retail environments, job sites, or long-term storage. The core of the roll is sturdy enough to prevent crushing, ensuring the strip remains flat and undamaged when unrolled, even after being stored for months.

Compatibility with cutting tools means no specialized equipment is needed—standard household tools like sharp scissors, utility knives, or wire cutters work for most rolls. The strip’s casing (typically silicone or PVC) is designed to be easy to cut without fraying, while the internal circuit board is reinforced near cutting points to avoid cracking. This accessibility makes the rolls ideal for DIY projects, where professional tools may not be available.

The ability to cut these rolls without compromising functionality relies on thoughtful engineering that protects the strip’s electrical and structural integrity. Isolated LED segments are the key to safe cutting: each section of the strip (between cutting marks) operates independently, with its own resistors, wiring, and LEDs. This means removing one segment does not affect the others—whether you cut the roll into 10 small pieces or two large lengths, each piece will light up reliably. This modular design also simplifies repairs: if one segment fails, it can be cut out and replaced without discarding the entire roll.

Reinforced cut zones strengthen the strip around each cutting mark, preventing damage when the knife or scissors make contact. The casing near these zones is slightly thicker or more durable, reducing the risk of tearing or fraying during cutting. For silicone-cased rolls, the material’s flexibility absorbs pressure from the cutting tool, ensuring a clean, straight cut that doesn’t leave jagged edges (which could trap moisture or cause injury).

Post-cut sealing solutions are often included with the roll, ensuring that trimmed ends maintain the strip’s original performance (including waterproofing, if applicable). Most rolls come with silicone end caps, heat-shrink tubing, or adhesive sealants that can be applied to the cut end to create a watertight, dustproof barrier. For waterproof models (e.g., IP65 or IP68), these seals are critical to preserving the strip’s resistance to moisture—without them, water could seep into the circuit board and cause short circuits.

Consistent voltage distribution ensures that even after cutting, the strip maintains uniform brightness across its length. The internal wiring is designed to balance power flow, preventing voltage drop (a common issue in non-cuttable strips that are too long). This means a 2-foot cut segment will be just as bright as a 20-foot segment, making the rolls suitable for both small accent lighting and large linear installations.

Cuttable neon flex strip rolls simplify installation by reducing prep time, minimizing waste, and adapting to diverse project requirements—whether for residential DIY or commercial construction. On-site measurement and cutting eliminate the need for pre-planning exact dimensions, a major advantage for projects with irregular or hard-to-measure spaces (e.g., curved walls, custom furniture, or asymmetrical signage). Users can unroll the strip, hold it against the installation surface to measure, mark the desired length, and cut—ensuring a precise fit without guesswork. This flexibility is especially valuable for renovation projects, where existing structures may have non-standard sizes.

Reduced waste and cost come from using only what is needed. Pre-cut strips often force users to buy longer lengths than required (leading to leftover material), but roll-form allows for exact cuts, lowering material costs and minimizing environmental impact. For commercial projects (like retail store builds or hotel renovations), this can translate to significant savings when ordering multiple rolls.

Easy joining of segments means multiple cut pieces from the same roll can be connected to create longer lengths, if needed. Most rolls are compatible with standard neon flex connectors (sold separately or included), which allow cut segments to be linked without compromising performance. These connectors are available in waterproof or non-waterproof versions, ensuring compatibility with the strip’s IP rating. For example, a user could cut three 10-foot segments from a 30-foot roll and join them to line a long hallway, or use each segment for separate under-cabinet installations.

Mounting flexibility aligns with the roll’s customizable nature. After cutting, the strip can be mounted using the same methods as pre-cut neon flex—adhesive backing for smooth surfaces, mounting clips for rough surfaces, or channels for permanent installations. The roll’s continuous design ensures that even long, uncut sections (e.g., 20 feet) can be mounted without seams, creating a seamless line of light that enhances aesthetics.

Cuttable neon flex strip rolls adapt to an unparalleled range of applications, thanks to their customizable length and flex properties. Residential projects benefit from their DIY-friendly design, with homeowners using them for under-cabinet lighting (cut to fit cabinet widths), mirror surrounds (trimmed to match mirror size), or stair riser lighting (cut into short segments for each step). The rolls are also ideal for temporary decor, such as holiday lighting or party backdrops—users can cut lengths to fit windows, doorframes, or furniture, then repurpose the remaining strip for future projects.

Commercial and retail spaces leverage their scalability for branding and functionality. Retail stores cut rolls to fit window displays, shelf edges, or signage, with the ability to adjust lengths as displays change seasonally. Restaurants and cafes use them to line bar tops (cut to the bar’s exact length), outline booths, or illuminate outdoor patios—customizing the lighting to match the venue’s layout. Hotels install them in guest rooms (e.g., under-bed lighting cut to mattress size) or along corridors (joined from multiple cut segments), ensuring consistent, tailored illumination.

Architectural and outdoor lighting projects rely on their ability to cover large areas. Building facades, rooflines, or columns can be lined with long, uncut sections from the roll, while curved features (like arches or domes) use shorter, cut segments to follow the shape. Outdoor pathways, garden borders, or pool edges (using waterproof rolls) are easily illuminated by cutting the roll to fit the path’s length, with no waste.

Event and temporary installations thrive on the rolls’ flexibility. Wedding planners cut them to create custom backdrops, table runners, or arch decorations, with the ability to adjust lengths on-site if the venue layout changes. Festival organizers use them to line stages, vendor booths, or walkways, cutting segments to fit each space and joining them for longer runs. The rolls’ compact size makes them easy to transport to remote event locations, where pre-cut strips might not fit unexpected needs.

Cuttable neon flex strip rolls retain the same durability and performance as non-cuttable neon flex—even after trimming—thanks to robust materials and construction. Casing durability ensures the strip withstands wear and tear, with options like UV-stabilized silicone (for outdoor use) or fire-retardant PVC (for indoor use). The casing is resistant to cracking, fading, or yellowing, even after cutting, and maintains its flexibility in extreme temperatures (from freezing winters to hot summers).

Waterproof options (available as IP65, IP67, or IP68-rated rolls) retain their moisture resistance after cutting, provided the cut end is properly sealed with the included end cap or sealant. This makes them suitable for wet environments like bathrooms, pools, or outdoor patios—users can cut the roll to fit around a shower enclosure or pool edge, seal the ends, and enjoy reliable waterproof performance.

LED longevity is unaffected by cutting, with the same lifespan as non-cuttable strips (typically tens of thousands of hours). The isolated LED segments ensure that cutting does not stress the diodes, and the reinforced cut zones prevent damage to the circuit board that could shorten LED life. This means a cut segment from a roll will last just as long as a full-length roll, providing long-term value.

Color consistency is maintained across all cut segments, as the LEDs are calibrated during manufacturing to emit uniform hues. Whether you cut a roll into 5 small pieces or use it as one long strip, each piece will match in color and brightness—critical for projects like retail displays or brand signage, where color accuracy is key.

Cuttable neon flex strip rolls offer economic and environmental benefits that extend beyond their customizable design. Lower material costs come from buying only what you need—no paying for pre-cut lengths that are too long. For example, a homeowner needing 7 feet of under-cabinet lighting can buy a 10-foot roll, cut 7 feet, and save the remaining 3 feet for future use, rather than buying two pre-cut 5-foot strips (and wasting 3 feet total). For commercial buyers ordering in bulk, this waste reduction translates to significant cost savings over time.

Reduced shipping and storage costs result from the rolls’ compact, lightweight design. A single 50-foot roll takes up far less space than 50 pre-cut 1-foot segments, lowering shipping fees and storage requirements. This is especially beneficial for retailers or contractors who stock multiple types of neon flex, as rolls occupy less shelf space and are easier to organize.

Sustainable practices are supported by minimal waste. By cutting only what is needed, users reduce the amount of neon flex that ends up in landfills—a key advantage over pre-cut strips, which often generate excess material. Additionally, many rolls are made from recyclable materials (like silicone or PVC) and use energy-efficient LEDs, aligning with green building standards and eco-friendly design goals.

Reusability means unused portions of the roll can be stored and reused for future projects. The protective packaging keeps the remaining strip safe, and the pre-marked cutting intervals remain visible, making it easy to cut additional lengths later. This reusability further reduces waste and increases the roll’s long-term value.

The market for cuttable neon flex strip rolls continues to evolve, with innovations that enhance their functionality, sustainability, and user experience. Smart roll technology integrates Bluetooth or Wi-Fi connectivity directly into the strip, allowing users to control color, brightness, or effects (via app or remote) even after cutting. These smart rolls maintain connectivity across cut segments (when joined with compatible connectors), enabling synchronized control of multiple pieces—ideal for large installations like home theaters or commercial lobbies.

Eco-friendly materials are becoming more prevalent, with manufacturers using recycled silicone/PVC for casings and lead-free solder for circuitry. Some rolls are also designed to be fully recyclable at the end of their lifespan, with clear instructions for separating components (casing, circuit board, LEDs) for proper recycling. This addresses growing demand for sustainable lighting solutions in both residential and commercial markets.

Enhanced cutting features include self-sealing cut zones in premium rolls—when cut, the casing automatically forms a temporary seal, eliminating the need for immediate end-cap application (though permanent sealing is still recommended for waterproof models). This simplifies on-site installation, especially for users working in tight spaces or without easy access to sealants.

Customizable roll lengths allow buyers to order rolls in non-standard lengths (e.g., 15 feet, 30 feet) rather than just standard sizes, further reducing waste. This made-to-order option is popular with commercial clients, such as restaurants or hotels, who have exact project dimensions and want to minimize excess material.

Cuttable neon flex strip rolls represent the pinnacle of customization in neon lighting, offering the freedom to tailor illumination to any project—large or small, simple or complex. Their roll-form design, safe cutting technology, and versatile applications make them indispensable for DIY enthusiasts, designers, and professionals alike, eliminating waste and ensuring a perfect fit every time. Whether used for residential accents, commercial branding, or architectural lighting, these rolls deliver reliable performance, durability, and value that pre-cut strips or rigid neon cannot match.

As technology advances, their integration with smart systems, sustainable materials, and enhanced cutting features will only strengthen their position as a go-to lighting solution. For anyone seeking flexible, scalable, and cost-effective neon lighting that adapts to their unique needs, cuttable neon flex strip rolls provide a versatile answer—proving that great lighting doesn’t have to be limited by pre-determined sizes.