Time:2025-07-10

The Dawn of Customizable Illumination with Cuttable Flexible Neon Strips

In the rapidly evolving landscape of modern lighting design, cuttable flexible neon strip lights have emerged as a transformative solution that bridges creativity with practicality. These innovative lighting systems combine the iconic appeal of neon illumination with unprecedented flexibility and precision, allowing users to tailor lighting layouts to any space or design vision. Unlike traditional rigid lighting fixtures, cuttable flexible neon strips can be easily trimmed to custom lengths and bent to fit complex contours, making them ideal for applications where adaptability and aesthetic precision are paramount.

As demand grows for personalized, energy-efficient lighting across residential, commercial, and industrial sectors, these strips offer a versatile platform for creating bespoke illuminated environments. This article delves into the technical marvels, design advantages, and diverse applications of cuttable flexible neon strip lights, providing a comprehensive guide for leveraging their potential in modern lighting projects.

Technical Excellence: Core Features of Cuttable Flexible Neon Strips

Precision Cuttable Design for Customization

The defining feature of these strips is their factory-engineered cuttable intervals, typically marked at regular increments (e.g., every 10–30mm) along the strip. These points align with the internal circuitry, allowing users to safely trim the strip to exact lengths using basic tools like scissors or utility knives. Each cut point is reinforced with exposed conductive pads or traces, ensuring consistent electrical connectivity even after multiple trims. This design eliminates waste and enables seamless integration into tight spaces or unique geometries, a critical advantage over fixed-length lighting solutions.

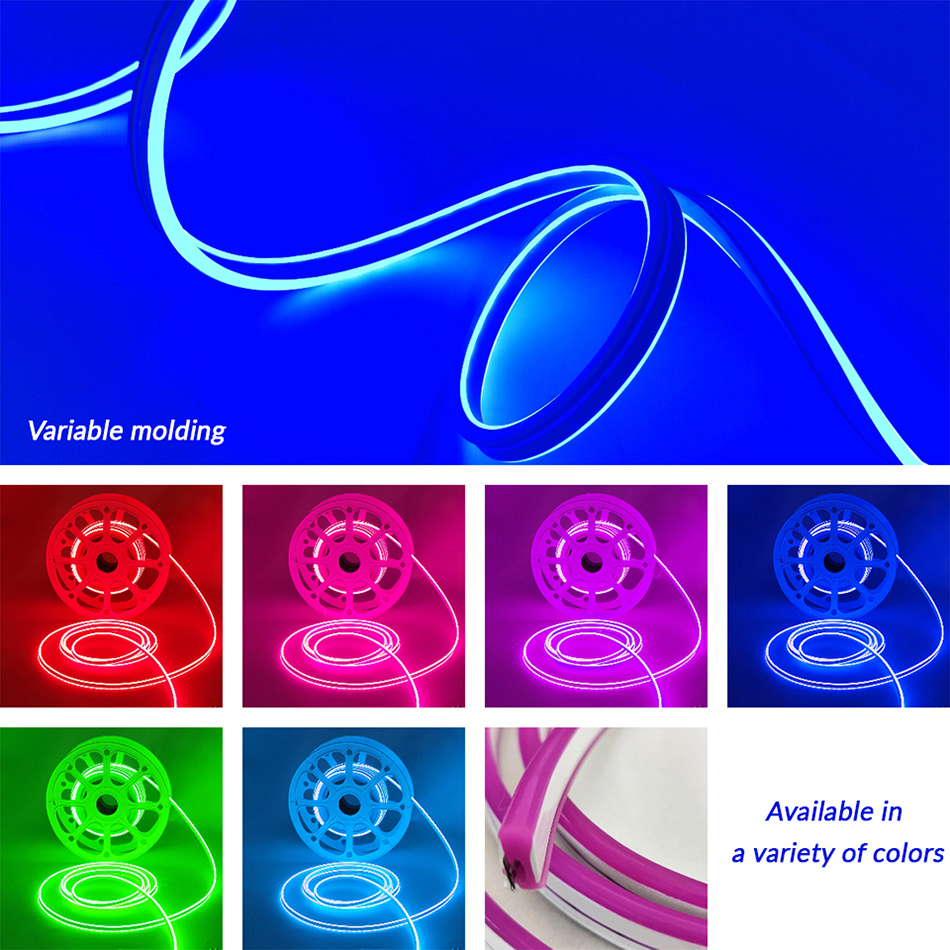

Unmatched Flexibility for Complex Installations

Material Innovation for Bending Performance

Flexible PCB Substrate: The strips are built on a bendable printed circuit board (PCB) that supports tight-radius bending (as low as 15mm in some models), conforming to curves, angles, and irregular surfaces without damage.

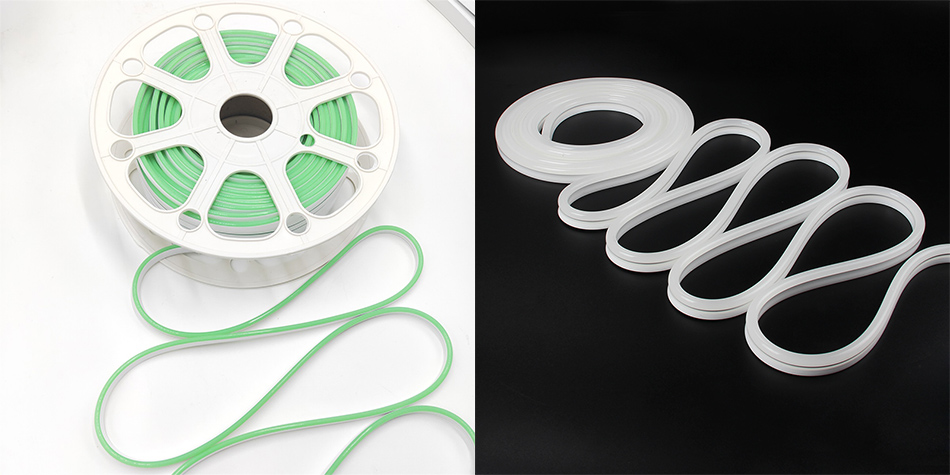

Silicone or PVC Encasing: A durable outer layer provides both protection and flexibility, with silicone variants offering superior resistance to temperature fluctuations, UV radiation, and physical impacts—ideal for outdoor or high-movement environments.

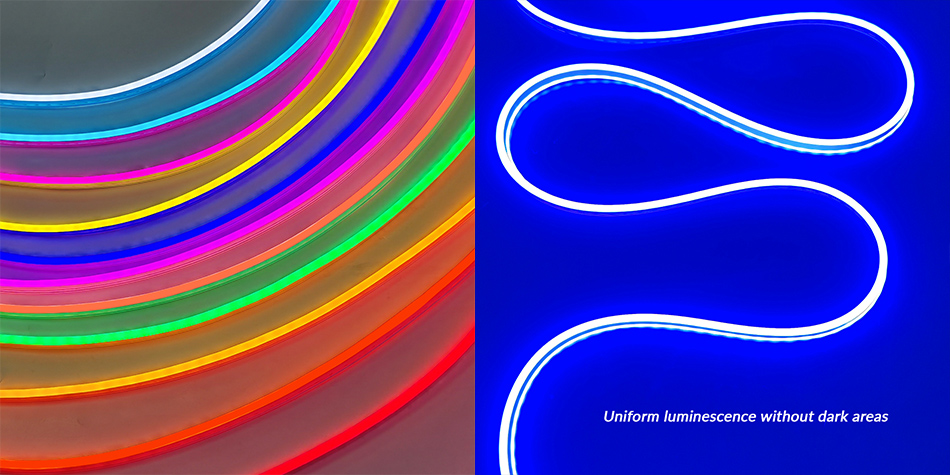

Seamless Contour Following

The combination of a flexible core and lightweight construction allows the strips to adhere to virtually any surface, from curved furniture and architectural moldings to cylindrical structures and uneven walls. This makes them ideal for creating continuous illuminated lines or intricate patterns that follow the natural contours of a space.

LED Technology for Efficient Illumination

At the heart of most cuttable flexible neon strips are energy-efficient LEDs, offering several advantages over traditional neon:

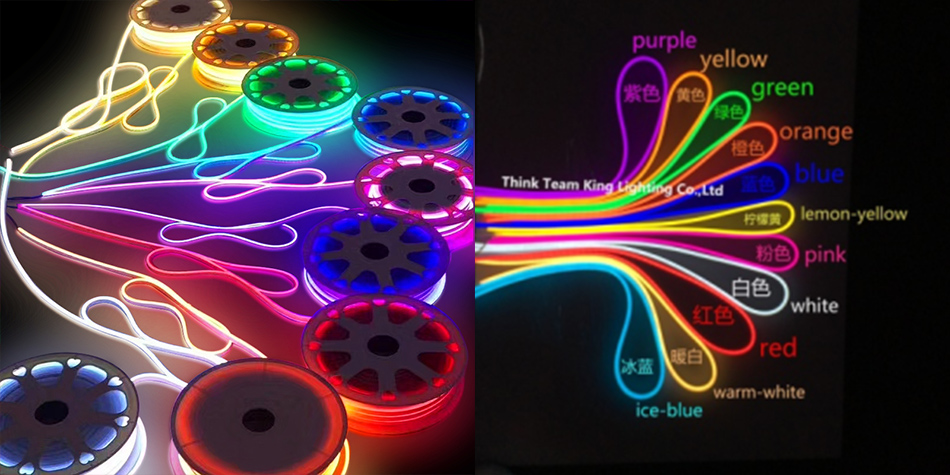

Vibrant Light Output: LEDs produce consistent, high-intensity light in a wide spectrum of colors, including RGB and white variants, with options for static hues or dynamic color-changing effects.

Low Heat Emission: Unlike incandescent or traditional neon, LED-based strips generate minimal heat, ensuring safety in close proximity to fabrics, plastics, or decorative elements.

Long Lifespan: With operational lifespans exceeding 50,000 hours, these strips reduce maintenance and replacement costs, a key benefit for large-scale or hard-to-reach installations.

Low-Voltage Safety and Compatibility

Operating at safe low voltages (12V or 24V DC), cuttable flexible neon strips prioritize user safety and ease of integration:

Plug-and-Play Power Solutions: Compatible with standard power adapters, batteries, or solar panels, they eliminate the need for high-voltage wiring, making them suitable for both indoor and off-grid outdoor projects.

Polarity-Protected Connectors: Most strips feature keyed connectors to prevent incorrect wiring, safeguarding against short circuits and ensuring hassle-free power integration.

Diverse Types of Cuttable Flexible Neon Strips

LED Neon Flex Strips: The Modern Workhorse

Construction: Ultra-flexible strips with surface-mounted LEDs encased in a translucent silicone or PVC sheath, mimicking the soft glow of traditional neon while offering superior durability.

Key Features:

High Brightness Uniformity: Dense LED placement (e.g., 30–60 LEDs per meter) ensures no dark spots, even after cutting.

Weather Resistance: IP65/IP67 ratings available for outdoor use, with waterproof variants suitable for pool areas, fountains, or rainy climates.

Ideal For: Residential decor, commercial signage, and outdoor landscaping where flexibility and weather resilience are essential.

Traditional Glass Neon Strips (Cuttable Editions)

Construction: Hand-bent glass tubes filled with neon or argon gas, engineered with pre-sealed cut points for safe trimming.

Key Features:

Authentic Neon Aesthetic: Emits the warm, nostalgic glow of vintage neon, perfect for retro-themed installations.

Indoor Excellence: Best suited for controlled environments due to glass fragility, often used in boutique stores, art galleries, or high-end residential spaces.

Considerations: Requires careful handling during cutting and installation, typically paired with protective mounting brackets.

Miniature Cuttable Neon Strips

Construction: Ultra-slim profiles (5–8mm width) with flexible PCBs, designed for intricate or space-constrained applications.

Key Features:

Micro-Precision Cutting: Cut points as close as 10mm apart, enabling detailed designs in small spaces.

Lightweight Design: Easily mounted with minimal adhesive, ideal for delicate projects like jewelry displays, model lighting, or bookshelf accents.

Ideal For: Craft projects, small-scale decor, and detailed interior design elements.

RGBW Cuttable Neon Strips

Construction: Multi-channel strips capable of producing millions of colors and white light variants, controlled via dimmable or smart controllers.

Key Features:

Dynamic Lighting Effects: Supports fades, strobes, and music-synchronized displays, perfect for event venues or commercial spaces requiring adaptable ambiance.

Color Temperature Tuning: Allows users to switch between warm, cool, and neutral white tones, enhancing versatility in residential and hospitality settings.

Ideal For: Restaurants, bars, and entertainment spaces where mood-based lighting is critical.

Unmatched Advantages for Modern Lighting Projects

Design Freedom Without Limits

Custom Geometry: Easily bend around 90-degree corners, circular arcs, or irregular shapes, transforming ordinary surfaces into illuminated artworks.

Modular Assembly: Cut and connect multiple strips to build complex layouts, such as geometric wall patterns, curved ceiling accents, or multi-level shelf lighting.

Effortless Installation for All Skill Levels

Tool-Free Cutting: Pre-marked intervals and user-friendly guides allow even novice users to achieve precise cuts without technical expertise.

Adhesive or Mechanical Mounting: Most strips feature strong adhesive backing for smooth surfaces, with optional clips or brackets for textured or heavy-duty installations.

Energy Efficiency and Cost Savings

Low Power Consumption: LEDs reduce energy use by up to 80% compared to traditional neon, lowering long-term operational costs.

Waste Reduction: Cut-to-length capability minimizes material waste, aligning with sustainable design principles.

Safety and Longevity

Child and Pet Safe: Low voltage and cool operation eliminate risks of electric shock or burns.

Durable Construction: Silicone-encased strips resist yellowing, cracking, and UV damage, ensuring consistent performance for years.

Diverse Applications Across Industries

Residential Lighting: Personalized Spaces with Professional Finish

Interior Decor

Cabinet & Shelving Lighting: Cut strips to fit kitchen cabinet undersides or bookshelf edges, creating seamless, shadow-free illumination.

Bedroom Ambiance: Wrap strips around headboards or mirrors for soft backlighting, adjustable via dimmer switches for personalized mood settings.

Bathroom Elegance: Waterproof strips along vanity mirrors or shower niches, enhancing functionality in high-moisture environments.

Outdoor Living

Garden Pathways: Guide pedestrians with cuttable strips along walkway edges, using weatherproof connectors for reliable outdoor performance.

Patio & Deck Lighting: Bend strips around railings or pergola beams, powered by solar chargers for eco-friendly nighttime ambiance.

Commercial & Retail: Enhancing Branding and Experience

Storefronts and Signage

Custom Channel Letters: Assemble logo outlines or store names with cuttable strips, adapting to any font or shape for memorable signage.

Window Displays: Create dynamic product showcases with color-changing strips, easily reconfigured for seasonal promotions.

Hospitality Venues

Restaurant Atmospheres: Line bar counters or dining booths with flexible strips, using RGBW variants to match daily themes (e.g., warm tones for dinners, vibrant hues for events).

Hotel Interiors: Illuminate elevator panels, lobby art installations, or guest room features with precision-cut strips for a luxurious finish.

Industrial & Functional Lighting: Safety and Efficiency

Workplace Safety

Machine and Equipment Lighting: Trim strips to highlight control panels, conveyor belts, or safety zones in factories, improving visibility and operational safety.

Warehouse Aisles: Install low-voltage strips along rack edges for energy-efficient aisle lighting, easily adjusted as storage layouts change.

Transportation Interiors

Vehicle Customization: Decorate car dashboards, RV cabinets, or aircraft galleys with flexible strips, conforming to curved surfaces in tight spaces.

Marine Applications: Waterproof strips on boat interiors or exteriors, enhancing navigation safety and onboard ambiance.

Step-by-Step Installation Guide

Phase 1: Planning Your Lighting Layout

Measure and Sketch: Use digital design tools or graph paper to map the installation area, noting dimensions, curves, and cut points needed.

Material Selection: Choose strip type (LED neon flex for outdoor, glass neon for vintage look) and connector type (waterproof for outdoor, snap-fit for easy reconfiguration).

Phase 2: Cutting the Strip to Size

Locate Cut Points: Identify manufacturer-marked intervals (symbols, dashed lines) and mark the desired length with a marker.

Precision Cutting: Use sharp scissors or a utility knife to trim at the marked point, ensuring a straight cut that exposes the PCB contacts without damage.

Phase 3: Connecting Segments (If Needed)

Prepare Connectors: For multi-segment layouts, use compatible connectors (e.g., snap-fit for LED flex, ceramic adapters for glass neon) to join strips end-to-end.

Power Integration: Connect the main power supply, ensuring correct polarity and using cable management to hide wires for a clean look.

Phase 4: Mounting the Strips

Adhesive Installation: Remove the protective film from the strip’s adhesive backing and press firmly onto a clean, dry surface, starting from one end to avoid bubbles.

Mechanical Mounting: For heavy or outdoor strips, secure with plastic clips or brackets every 15–30cm, especially around corners or curves.

Phase 5: Testing and Finishing

Function Test: Power on the system to check for uniform illumination and secure connections; re-seat any connectors with inconsistent light output.

Weatherproofing (Outdoor): Apply a thin layer of silicone sealant around connectors and cut ends to enhance water resistance, especially in exposed areas.

Key Considerations When Selecting Cuttable Flexible Neon Strips

Application-Specific Features

Environmental Conditions:

Indoor: Prioritize slim profiles and adhesive-backed strips for easy installation.

Outdoor: Choose IP65/IP67-rated strips with UV-resistant coatings and waterproof connectors.

Design Complexity: For intricate curves or tight spaces, opt for strips with a minimum bend radius that matches your project’s requirements.

Lighting Performance

Brightness and Color: Select LED density (e.g., higher LEDs per meter for intense illumination) and color technology (RGB for versatility, single-color for simplicity).

Dimming Capability: Ensure compatibility with dimmer switches or smart controllers if adjustable ambiance is needed.

Certification and Compliance

Safety Standards: Look for CE, UL, or IEC certifications to ensure electrical safety, especially for commercial installations.

Environmental Compliance: RoHS-compliant strips are free from hazardous materials, essential for indoor use in residential or office spaces.

Supplier and Support

Product Warranty: Reputable suppliers offer warranties on strip durability and connector performance, ensuring long-term reliability.

Technical Resources: Choose suppliers providing detailed installation guides, video tutorials, and customer support for troubleshooting.

Addressing Common Installation Challenges

Challenge 1: Inaccurate Cuts Leading to Malfunction

Root Cause: Cutting outside manufacturer-marked intervals or fraying PCB contacts.

Solution: Always use sharp tools and follow marked cut points; test cut segments with a power supply before final installation.

Challenge 2: Difficulty Bending Strips Without Damaging LEDs

Root Cause: Exceeding the strip’s minimum bend radius or applying excessive force.

Solution: Pre-warm silicone strips with a hairdryer (low heat) to enhance flexibility, and use bending templates for consistent curves.

Challenge 3: Adhesive Failure on Textured Surfaces

Root Cause: Inadequate surface preparation or low-tack adhesive for rough materials.

Solution: Clean surfaces with isopropyl alcohol and use dual-lock mounting tape or mechanical clips for added security on textured walls or wood.

Challenge 4: Voltage Drop in Long Strips

Root Cause: Undersized wiring or excessive length without a power booster.

Solution: Use 22AWG or thicker cables for runs over 5 meters, and position power supplies centrally to minimize voltage loss.

Innovations Shaping the Future of Cuttable Flexible Neon Strips

Smart Integration for Automated Control

Bluetooth and Wi-Fi Connectivity: Strips with built-in controllers allow users to adjust colors, brightness, and effects via smartphone apps or voice assistants like Alexa/Google Assistant.

Sensor Technology: Motion-activated strips auto-illuminate when detecting movement, ideal for hallway lighting or closet organization.

Sustainable Materials and Production

Recycled Silicone and PVC: Manufacturers are increasingly using post-consumer recycled materials for casings, reducing environmental impact without compromising performance.

Energy-Efficient LEDs: New generations of LEDs offer 30% higher efficiency, aligning with global sustainability goals.

Advanced Manufacturing for Precision

Laser-Precision Cutting: Automated systems ensure micro-precise cut points, enabling intricate designs in high-volume production.

3D-Printed Accessories: Customizable mounting brackets and connectors created via 3D printing, adapting to unique project geometries.

Hybrid Systems for Versatility

Dual-Technology Strips: Combining LED neon flex with traditional neon elements for hybrid installations that blend modern efficiency with vintage aesthetics.

Modular Kits: All-in-one packages including strips, connectors, power supplies, and mounting hardware, simplifying project planning for DIY enthusiasts.

Conclusion: Illuminating the Future with Flexibility and Precision

Cuttable flexible neon strip lights represent a landmark advancement in lighting technology, offering a rare combination of creativity, practicality, and reliability. Whether transforming a home into a personalized haven, enhancing a brand’s visual identity, or improving safety in industrial settings, these strips empower users to reimagine spaces with unprecedented ease.

As technology continues to evolve, the integration of smart controls, sustainable materials, and advanced manufacturing will only expand their potential. By prioritizing quality, compatibility, and user-friendly design, cuttable flexible neon strips are not just a lighting solution—they are a canvas for innovation, enabling anyone to turn architectural visions into illuminated realities. In a world where customization and efficiency are paramount, these strips stand as a testament to how technology can enhance both form and function, one precise cut at a time.