Time:2025-06-21

In the ever - evolving landscape of the lighting industry, manufacturers of silicone neon light strips play a pivotal role in shaping the way spaces are illuminated. These manufacturers are at the forefront of producing versatile, durable, and aesthetically pleasing lighting solutions that cater to a wide range of applications, from residential decor to commercial signage and architectural enhancements. This article delves deep into the world of silicone neon light strip manufacturers, exploring their production processes, product features, market significance, and the factors that set them apart in a competitive market.

The Production Process of Silicone Neon Light Strips

Material Sourcing and Preparation

The journey of creating high - quality silicone neon light strips begins with meticulous material sourcing. Manufacturers carefully select top - grade silicone, which serves as the protective casing for the internal components. This silicone is chosen for its excellent flexibility, durability, and resistance to environmental factors such as moisture, UV rays, and temperature variations. It not only safeguards the LED chips and circuit boards but also contributes to the even diffusion of light, creating a soft and consistent glow.

For the LED chips, manufacturers source from reputable suppliers known for their quality and performance. These chips are the heart of the neon light strips, responsible for generating the light. Along with the LED chips, high - quality circuit boards are selected. These boards are designed to provide a stable electrical connection and efficient power distribution to the LEDs, ensuring optimal performance and longevity. Once the materials are sourced, they undergo a series of preparation steps, including cleaning and cutting, to ensure they are ready for the assembly process.

Assembly and Encapsulation

The assembly process of silicone neon light strips is a precise and intricate operation. The LED chips are carefully mounted onto the circuit boards using advanced soldering techniques. This requires a high level of skill to ensure that each chip is properly connected, as even a minor soldering defect can affect the overall performance of the strip.

After the LED chips are mounted, the circuit board is encapsulated within the silicone casing. This is typically done through an extrusion process, where the silicone is heated and forced through a die to form a continuous tube that encases the circuit board and LEDs. The extrusion process ensures a seamless and uniform coating of silicone, providing maximum protection to the internal components while maintaining the flexibility of the strip. During this stage, quality control measures are strictly implemented to check for any air bubbles, uneven thickness, or other defects in the silicone casing.

Testing and Quality Assurance

Before the silicone neon light strips are ready for the market, they undergo rigorous testing procedures. Electrical testing is carried out to verify the proper functioning of the LEDs and the circuit board. This includes checking for correct voltage and current requirements, ensuring that the strips do not flicker or experience electrical malfunctions.

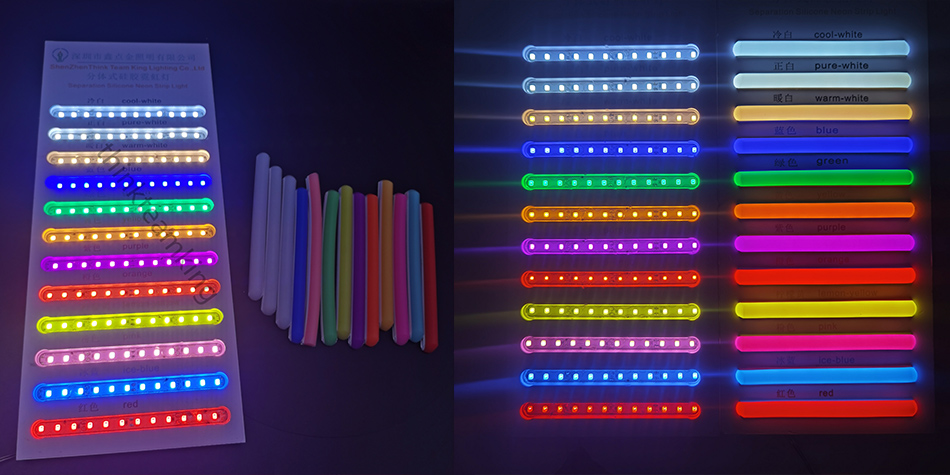

Optical testing is also crucial, where the brightness, color accuracy, and color consistency of the light emitted by the strips are evaluated. The strips are tested under various lighting conditions to ensure that they meet the desired specifications. Additionally, mechanical testing is performed to assess the flexibility and durability of the strips. They are bent, twisted, and subjected to physical stress to ensure that they can withstand normal handling and installation without damage. Only after passing all these comprehensive tests are the silicone neon light strips approved for packaging and distribution.

Key Features of Silicone Neon Light Strips

Flexibility and Versatility

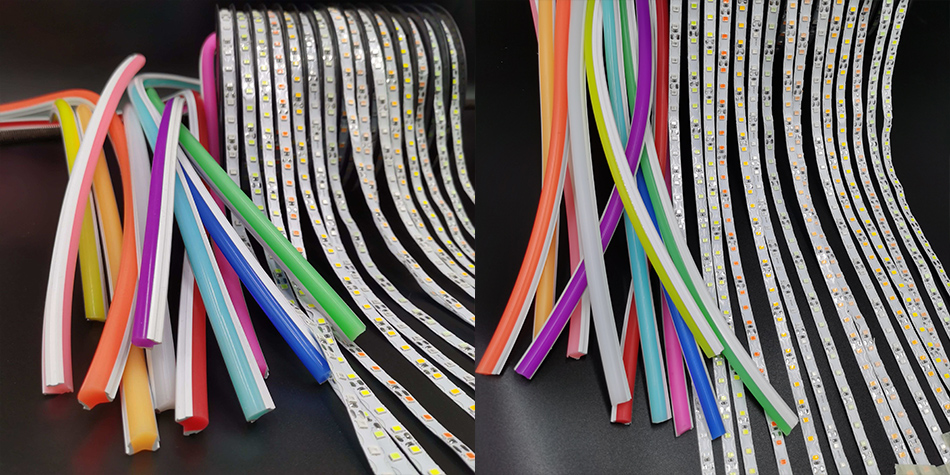

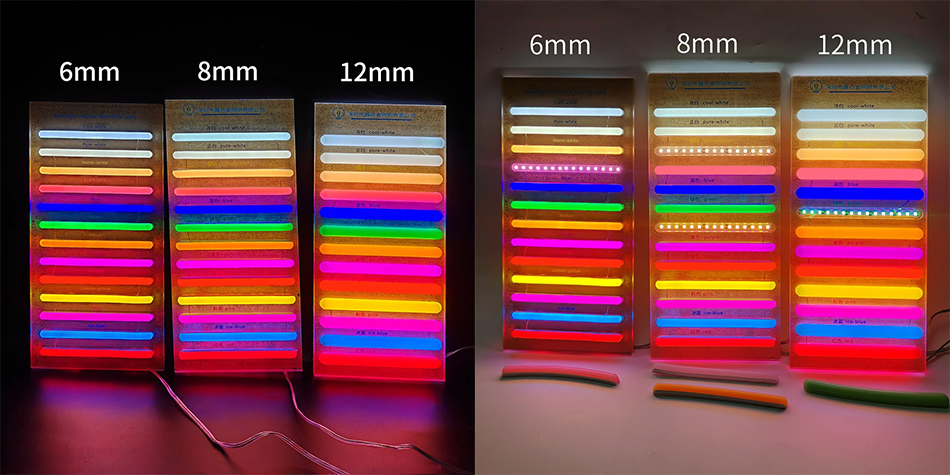

One of the most notable features of silicone neon light strips is their flexibility. The soft and pliable silicone casing allows the strips to be easily bent, curved, and shaped to fit various surfaces and contours. This makes them ideal for a wide range of applications, from wrapping around columns and beams in architectural projects to creating custom - shaped lighting designs in interior decor.

The versatility of these strips extends beyond their physical form. They are available in a wide range of colors, from warm and inviting hues to vibrant and bold shades. Some strips also offer color - changing capabilities, either through pre - set patterns or the ability to be controlled remotely. This allows users to create dynamic and engaging lighting displays that can be customized to suit different moods, occasions, and environments.

Durability and Longevity

Silicone neon light strips are designed to be highly durable. The silicone casing provides excellent protection against physical damage, moisture, and UV radiation. This makes them suitable for both indoor and outdoor use. In outdoor applications, they can withstand harsh weather conditions, such as rain, snow, and extreme temperatures, without deteriorating or losing their performance.

The use of high - quality LED chips and circuit boards also contributes to the long lifespan of these strips. LEDs have a significantly longer lifespan compared to traditional lighting sources, reducing the need for frequent replacements. With proper installation and maintenance, silicone neon light strips can provide reliable and consistent illumination for many years, making them a cost - effective lighting solution in the long run.

Energy Efficiency

Energy efficiency is a key advantage of silicone neon light strips. LED technology, which is the foundation of these strips, is known for its high energy - conversion efficiency. LEDs consume significantly less power compared to traditional incandescent or fluorescent lights while producing the same amount of light. This not only helps users reduce their electricity bills but also makes these strips an environmentally friendly lighting option by reducing energy consumption and carbon emissions.

Applications of Silicone Neon Light Strips

Residential Interior Decor

In residential settings, silicone neon light strips are widely used to enhance the aesthetic appeal and functionality of interior spaces. In the living room, they can be installed behind the TV, along the ceiling coves, or under furniture to create a cozy and inviting atmosphere. The soft glow of the strips can also be used to highlight architectural features, such as exposed beams or decorative moldings, adding depth and character to the room.

In the bedroom, these strips can be placed behind the headboard, around mirrors, or under the bed to create a relaxing and romantic ambiance. They can also serve as nightlights, providing a gentle illumination without disturbing sleep. In the kitchen, silicone neon light strips are ideal for under - cabinet lighting, providing task illumination while adding a modern touch to the space.

Commercial and Retail Spaces

For commercial and retail establishments, silicone neon light strips are a powerful marketing and branding tool. In retail stores, they can be used to create eye - catching window displays, highlight product shelves, and enhance the overall shopping experience. The ability to customize the color and lighting effects allows businesses to create a unique visual identity that attracts customers and differentiates them from competitors.

In restaurants and cafes, these strips can be used to set the mood and create a distinctive dining atmosphere. They can be installed along the walls, around the bar area, or under the tables to create a warm and inviting environment. In offices and other commercial spaces, silicone neon light strips can be used to decorate common areas, such as lobbies, corridors, and meeting rooms, adding a touch of creativity and professionalism.

Architectural and Landscape Lighting

In architecture, silicone neon light strips are used to accentuate the unique features of buildings. They can be installed along the edges of roofs, eaves, windows, and doors to create a striking nighttime presence. The soft, glowing lines add depth and dimension to the building's facade, enhancing its aesthetic appeal.

In landscape lighting, these strips are used to illuminate pathways, gardens, and outdoor structures. They can be installed along the edges of walkways, around trees and shrubs, or under benches and pergolas to create a safe and inviting outdoor environment. The flexibility of the strips allows for creative installations that highlight the natural beauty of the landscape.

Choosing the Right Silicone Neon Light Strip Manufacturer

Quality and Reputation

When selecting a manufacturer of silicone neon light strips, quality should be the top priority. Look for manufacturers with a proven track record of producing high - quality products. Read customer reviews and testimonials to get an idea of the manufacturer's reputation in the market. A reputable manufacturer will use high - quality materials, employ strict quality control measures, and offer reliable after - sales support.

Check for certifications, such as CE, UL, and RoHS, which indicate that the manufacturer's products meet international safety and quality standards. These certifications ensure that the silicone neon light strips are safe to use, free from hazardous substances, and have been tested for electrical and optical performance.

Customization Capabilities

The ability to customize silicone neon light strips is an important factor to consider. Different projects may have unique requirements in terms of color, length, shape, and functionality. A good manufacturer should be able to offer a wide range of customization options to meet these specific needs.

Whether it's creating a custom - colored strip to match a brand's logo, cutting the strips to a specific length for a particular installation, or integrating special features such as dimming capabilities or motion sensors, the manufacturer should have the expertise and resources to bring your vision to life.

Pricing and Customer Service

While price should not be the sole determining factor, it is an important consideration. Compare the prices of different manufacturers to ensure you are getting a competitive deal. However, be wary of manufacturers offering prices that seem too good to be true, as this may indicate lower - quality products.

In addition to pricing, excellent customer service is essential. A reliable manufacturer should be responsive to your inquiries, provide clear and accurate information, and offer support throughout the purchasing process. They should also be willing to address any issues or concerns that may arise after the sale, ensuring a smooth and satisfactory experience.

Market Trends and Future Outlook for Silicone Neon Light Strip Manufacturers

Smart Lighting Integration

The future of silicone neon light strips lies in smart lighting integration. With the increasing popularity of smart home and building automation systems, there is a growing demand for lighting products that can be controlled remotely and integrated with other smart devices. Manufacturers are expected to develop silicone neon light strips with advanced connectivity features, such as Wi - Fi, Bluetooth, or Zigbee, allowing users to control the lighting from their smartphones, tablets, or smart home hubs.

Smart lighting integration will also enable more advanced features, such as voice - controlled lighting, automatic dimming based on ambient light levels, and synchronization with music or other media. This will provide users with a more convenient, personalized, and energy - efficient lighting experience.

Sustainable Manufacturing Practices

As environmental awareness continues to grow, there is an increasing demand for sustainable and eco - friendly lighting solutions. Silicone neon light strip manufacturers are likely to adopt more sustainable manufacturing practices, such as using recycled materials, reducing energy consumption during production, and implementing waste - reduction and recycling programs.

Manufacturers may also focus on developing products with a longer lifespan and lower environmental impact. This could include using more energy - efficient LED chips, improving the durability of the silicone casing, and ensuring that the products are easily recyclable at the end of their lifespan.

Technological Advancements

The lighting industry is constantly evolving, and silicone neon light strip manufacturers need to stay ahead of the curve by embracing technological advancements. This includes the development of new LED technologies that offer higher brightness, better color rendering, and longer lifespan.

Advancements in materials science may also lead to the creation of new types of silicone with improved properties, such as enhanced flexibility, better heat resistance, and increased light - transmission. Additionally, manufacturers may explore new manufacturing techniques to improve production efficiency, reduce costs, and increase the quality of their products.

Challenges Faced by Silicone Neon Light Strip Manufacturers

Intense Market Competition

The market for silicone neon light strips is highly competitive, with numerous manufacturers vying for market share. This competition puts pressure on manufacturers to constantly improve their products, reduce costs, and differentiate themselves from their competitors.

To stay competitive, manufacturers need to invest in research and development, focus on innovation, and offer high - quality products at competitive prices. They also need to build strong brand identities and establish good relationships with customers to gain a competitive edge in the market.

Fluctuations in Raw Material Prices

The prices of raw materials used in the production of silicone neon light strips, such as silicone, LED chips, and circuit boards, can be subject to fluctuations. These fluctuations can be caused by various factors, including changes in global supply and demand, geopolitical events, and currency exchange rate fluctuations.

Fluctuations in raw material prices can significantly impact the production costs of manufacturers. To mitigate this risk, manufacturers need to develop effective supply chain management strategies, such as establishing long - term partnerships with reliable suppliers, diversifying their raw material sources, and implementing cost - control measures.

Meeting Regulatory Requirements

The lighting industry is subject to a complex and evolving set of regulations related to safety, energy efficiency, and environmental protection. Silicone neon light strip manufacturers need to stay updated on these regulations and ensure that their products comply with the latest requirements.

Meeting regulatory requirements often requires manufacturers to invest in research and development, upgrade their production facilities, and implement new quality control measures. Failure to comply with these regulations can result in product recalls, fines, and damage to the manufacturer's reputation.

Conclusion

Manufacturers of silicone neon light strips play a crucial role in the lighting industry, providing innovative and high - quality lighting solutions for a wide range of applications. Their production processes, product features, and market significance are key factors that contribute to the success of the industry.

When choosing a silicone neon light strip manufacturer, it is important to consider factors such as quality, reputation, customization capabilities, pricing, and customer service. As the market continues to evolve, manufacturers need to adapt to new trends, such as smart lighting integration, sustainable manufacturing practices, and technological advancements, to stay competitive.

Despite the challenges they face, such as intense market competition, fluctuations in raw material prices, and meeting regulatory requirements, silicone neon light strip manufacturers have the opportunity to thrive in the industry by focusing on innovation, quality, and customer satisfaction. With the right strategies and approaches, they can continue to illuminate the world with their innovative lighting solutions.