Time:2025-06-23

In the dynamic landscape of modern lighting solutions, the demand for reliable, energy - efficient, and durable lighting options has never been higher. Low - power silicone neon strips designed for 24/7 operation have emerged as a game - changing product, catering to a wide range of applications where continuous illumination is required. These strips not only offer a visually appealing lighting solution but also come with a host of technical and practical advantages. This article delves deep into the world of low - power silicone neon strips for round - the - clock operation, exploring their technology, benefits, manufacturing process, applications, and the factors to consider when choosing them.

The Technology Underpinning Low - Power Silicone Neon Strips

LED - Based Lighting Source

At the heart of low - power silicone neon strips lies LED (Light - Emitting Diode) technology. LEDs are semiconductor devices that convert electrical energy into light. The key to their low - power consumption lies in their high energy - conversion efficiency. Unlike traditional incandescent bulbs, which waste a significant amount of energy in the form of heat, LEDs emit light with minimal heat generation. This is due to their unique structure, where a forward - biased semiconductor junction allows electrons and holes to recombine, releasing photons in the process. The materials used in the semiconductor, such as gallium nitride (GaN) or indium gallium nitride (InGaN), are carefully selected to optimize the emission of light at specific wavelengths, resulting in a wide range of color options for the neon strips.

Power Management Systems

To ensure the neon strips can operate efficiently for 24/7, advanced power management systems are integrated. These systems are designed to regulate the electrical current flowing through the LEDs precisely. By maintaining a stable and optimal current, the LEDs can operate at their peak efficiency, consuming the least amount of power while still providing sufficient illumination. Pulse - Width Modulation (PWM) is a commonly used technique in power management for these strips. PWM works by rapidly switching the power supply to the LEDs on and off at a high frequency. By adjusting the duty cycle (the proportion of time the power is on compared to the total cycle time), the average power delivered to the LEDs can be controlled, enabling dimming capabilities while maintaining energy efficiency.

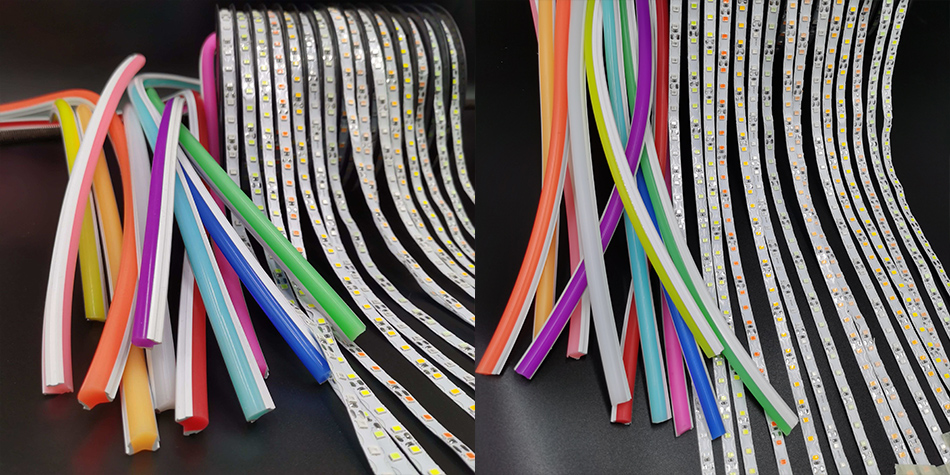

Silicone Encapsulation for Durability

The silicone casing of these neon strips plays a crucial role in their ability to withstand continuous operation. Silicone is a highly durable and flexible material. It provides excellent protection to the internal components, especially the LEDs and the circuit board. The silicone encapsulation acts as a barrier against moisture, dust, and physical damage. In applications where the strips are exposed to harsh environmental conditions, such as outdoor signage or industrial settings, the silicone casing ensures the longevity of the product. Its flexibility also allows the strips to be bent and shaped to fit various surfaces and installation requirements without compromising the integrity of the internal components.

Advantages of Low - Power Silicone Neon Strips for 24/7 Operation

Energy Efficiency and Cost Savings

The low - power consumption of these neon strips is a significant advantage, especially for applications that require continuous illumination. Over time, the energy savings can be substantial. For example, in commercial buildings where neon strips are used for 24 - hour signage or in industrial facilities for continuous work area lighting, the reduced power consumption directly translates into lower electricity bills. Additionally, the long lifespan of LEDs in these strips means less frequent replacements, further reducing maintenance costs. This combination of energy efficiency and low maintenance makes low - power silicone neon strips a cost - effective lighting solution in the long run.

Durability and Reliability

The use of high - quality silicone and advanced manufacturing techniques results in neon strips that are highly durable. The silicone casing protects the LEDs from environmental factors, and the robust construction of the circuit board ensures stable performance. These strips can withstand temperature variations, humidity, and mechanical stress, making them suitable for a wide range of operating conditions. In applications such as 24 - hour convenience stores, gas stations, or security - related lighting, the reliability of the lighting system is crucial. Low - power silicone neon strips offer the assurance of continuous and consistent illumination, minimizing the risk of disruptions due to lighting failures.

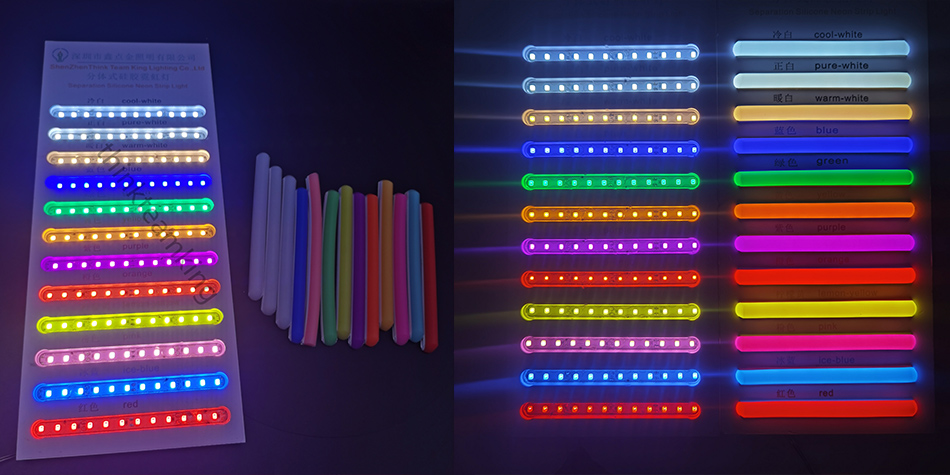

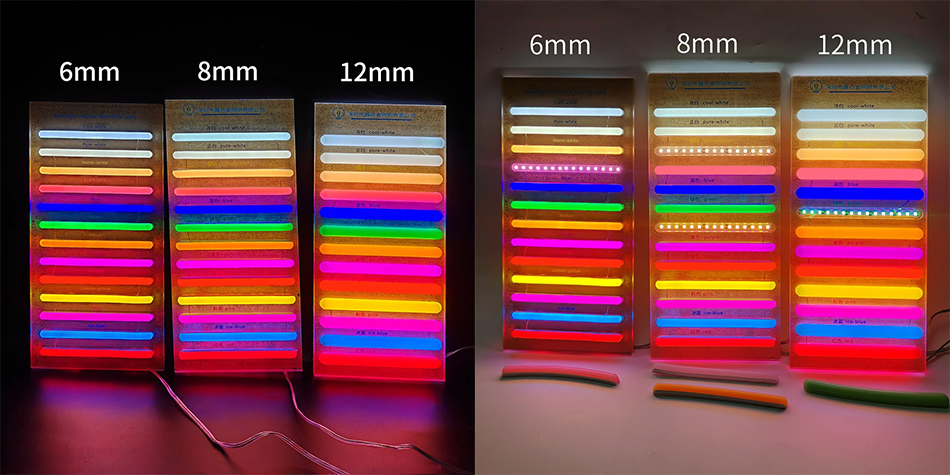

Aesthetic Appeal and Customization

Low - power silicone neon strips come in a variety of colors and can be customized to fit specific design requirements. The soft, even glow of the strips creates an aesthetically pleasing lighting effect, enhancing the visual appeal of any space. Whether used for decorative purposes in restaurants, hotels, or for creating a unique atmosphere in retail stores, the ability to customize the color, length, and shape of the strips allows for creative and personalized lighting designs. The flexibility of the silicone material also enables the strips to be bent into intricate shapes, adding a touch of creativity to architectural lighting projects.

The Manufacturing Process of Low - Power Silicone Neon Strips

Material Selection

The manufacturing process begins with the careful selection of materials. High - quality LEDs are sourced from reputable manufacturers known for their reliability and efficiency. The silicone used for encapsulation is chosen for its specific properties, such as high flexibility, excellent heat resistance, and good light - transmission characteristics. The circuit board materials are selected to ensure proper electrical conductivity and heat dissipation. Additionally, other components like connectors and mounting hardware are chosen for their durability and compatibility with the overall design.

LED Mounting and Circuit Board Assembly

The LEDs are precisely mounted onto the circuit board using surface - mount technology (SMT). This process requires high - precision equipment to ensure that each LED is correctly placed and soldered. The circuit board is designed to distribute the electrical current evenly to all the LEDs, and it may also incorporate components for power regulation and protection. After the LEDs are mounted, the circuit board is thoroughly tested to ensure that all the connections are secure and that the LEDs are functioning correctly.

Silicone Encapsulation

Once the circuit board assembly is complete, it is encapsulated in silicone. There are different methods of silicone encapsulation, with extrusion being a common one. In the extrusion process, the circuit board is fed through a die along with liquid silicone. The silicone is then cured, forming a seamless and protective casing around the circuit board and LEDs. This process ensures that the internal components are fully protected and that the strip has a smooth and uniform appearance. After encapsulation, the strips are again tested for any potential defects, such as air bubbles in the silicone or electrical malfunctions.

Quality Control and Testing

Stringent quality control measures are implemented throughout the manufacturing process. Electrical tests are conducted to verify the proper functioning of the strips, including checking for correct voltage requirements, current consumption, and LED performance. Optical tests are carried out to ensure that the color, brightness, and light distribution meet the specified standards. Mechanical tests are also performed to assess the flexibility and durability of the silicone casing. The strips are subjected to stress tests, such as bending, twisting, and temperature cycling, to ensure that they can withstand the rigors of continuous operation. Only strips that pass all these comprehensive tests are approved for distribution.

Applications of Low - Power Silicone Neon Strips for 24/7 Operation

Commercial and Retail Spaces

In commercial and retail environments, low - power silicone neon strips find extensive use. In 24 - hour convenience stores, they are used for aisle lighting, signage, and to highlight product displays. The bright and energy - efficient illumination provided by these strips not only makes the store more inviting but also helps customers easily locate products. In shopping malls, neon strips can be used for architectural accents, such as along the edges of escalators or to outline storefronts. Retail stores often use them for creating a unique brand - specific lighting design that can attract customers even during late - night hours.

Industrial and Manufacturing Facilities

Industrial facilities require reliable and continuous lighting for safety and operational efficiency. Low - power silicone neon strips can be used to illuminate work areas, walkways, and machinery. Their durability and ability to withstand harsh industrial environments, such as high temperatures, dust, and vibrations, make them an ideal choice. In manufacturing plants, these strips can be used to mark areas, provide task lighting, and enhance overall visibility, ensuring that workers can operate safely and efficiently around the clock.

Outdoor Signage and Advertising

Outdoor signage and advertising boards often need to be illuminated 24/7 to attract attention at all times. Low - power silicone neon strips are well - suited for this purpose. They can be used to outline the shape of a sign, highlight specific messages, or create dynamic lighting effects. The weather - resistant properties of the silicone casing ensure that the strips can withstand rain, sunlight, and temperature fluctuations, maintaining their performance and visual appeal over time.

Transportation and Public Spaces

In transportation hubs like airports, train stations, and bus terminals, continuous lighting is essential for passenger safety and guidance. Low - power silicone neon strips can be used to illuminate walkways, staircases, and waiting areas. They can also be used for decorative purposes, such as in the design of terminal interiors. In public spaces like parks, plazas, and bridges, these strips can be used for architectural lighting, creating a visually appealing and safe environment for people to use day and night.

Choosing the Right Low - Power Silicone Neon Strips

Assessing Power Consumption

When choosing low - power silicone neon strips, it is crucial to assess their power consumption accurately. Look for strips that are labeled with their power requirements and compare them based on your specific energy - efficiency goals. Consider the length of the strip and the number of LEDs it contains, as these factors can affect power consumption. Additionally, check for any certifications or ratings related to energy efficiency, such as ENERGY STAR ratings in some regions.

Evaluating Durability and Build Quality

Examine the construction of the strips to ensure they are durable enough for 24/7 operation. The silicone casing should be thick and free of defects. Check for any signs of poor manufacturing, such as uneven encapsulation or loose connections. Look for products that come with a warranty, as this indicates the manufacturer's confidence in the product's durability. Consider the strip's ability to withstand environmental factors, such as moisture, UV rays, and temperature changes, especially if it will be used outdoors or in harsh environments.

Considering Color and Lighting Effects

Based on your application, choose strips with the appropriate color and lighting effects. Whether you need a single - color strip for a minimalist design or a multi - color, programmable strip for a more dynamic display, make sure the product meets your aesthetic requirements. Test the color accuracy and brightness of the strips before making a purchase. Some strips may offer features like dimming or color - changing capabilities, which can be useful depending on the intended use.

Supplier Reputation and Customer Support

Research the reputation of the supplier or manufacturer. Read customer reviews and testimonials to get an idea of the quality of their products and their customer service. A reliable supplier will be able to provide technical support, answer your questions, and offer assistance in case of any issues. Consider factors such as the supplier's experience in the industry, their production capacity, and their ability to meet your specific order requirements.

Future Trends in Low - Power Silicone Neon Strips for 24/7 Operation

Smart Lighting Integration

The future of low - power silicone neon strips is likely to involve more integration with smart lighting systems. This could include the ability to control the strips remotely via a smartphone app, voice - controlled operation through virtual assistants like Amazon Alexa or Google Assistant, and integration with building management systems. Smart lighting features such as automated dimming based on ambient light levels, scheduling, and the ability to create custom lighting scenes will enhance the functionality and convenience of these strips.

Advancements in LED Technology

Ongoing research and development in LED technology will lead to even more efficient and powerful LEDs. Future low - power silicone neon strips may feature LEDs with higher lumen - per - watt ratios, allowing for brighter illumination with even lower power consumption. New materials and manufacturing techniques in LED production may also result in more durable and reliable LEDs, further extending the lifespan of the neon strips.

Sustainable Manufacturing Practices

As environmental concerns continue to grow, there will be an increasing focus on sustainable manufacturing practices in the production of low - power silicone neon strips. Manufacturers may use more recycled materials in the production of the silicone casing and the circuit boards. Energy - efficient manufacturing processes will be adopted to reduce the overall carbon footprint of the production. Additionally, efforts may be made to make the strips more easily recyclable at the end of their lifespan.

Conclusion

Low - power silicone neon strips for 24/7 operation offer a compelling lighting solution for a wide range of applications. Their energy - efficient LED technology, durable silicone encapsulation, and aesthetic versatility make them a popular choice in commercial, industrial, outdoor, and public space lighting. When choosing these strips, it is important to consider factors such as power consumption, durability, color options, and the reputation of the supplier. As technology continues to advance, we can expect to see even more innovative and sustainable low - power silicone neon strips in the future, further enhancing their performance and application potential. By understanding the technology, benefits, and considerations associated with these strips, users can make informed decisions and enjoy the advantages of continuous, efficient, and visually appealing illumination.