Time:2025-06-28

In the challenging maritime environment, where saltwater, humidity, and harsh weather conditions prevail, lighting solutions need to be both robust and efficient. Saltwater-resistant silicone neon strips for boats have emerged as an ideal choice, combining durability, functionality, and aesthetic appeal to meet the specific requirements of marine applications. These strips are engineered to withstand the corrosive effects of saltwater while enhancing the safety, convenience, and visual allure of boats. This article will comprehensively explore saltwater-resistant silicone neon strips for boats, covering their construction, key features, diverse applications, installation considerations, maintenance practices, and future trends.

The Construction and Technology of Saltwater-Resistant Silicone Neon Strips for Boats

The Silicone Encapsulation

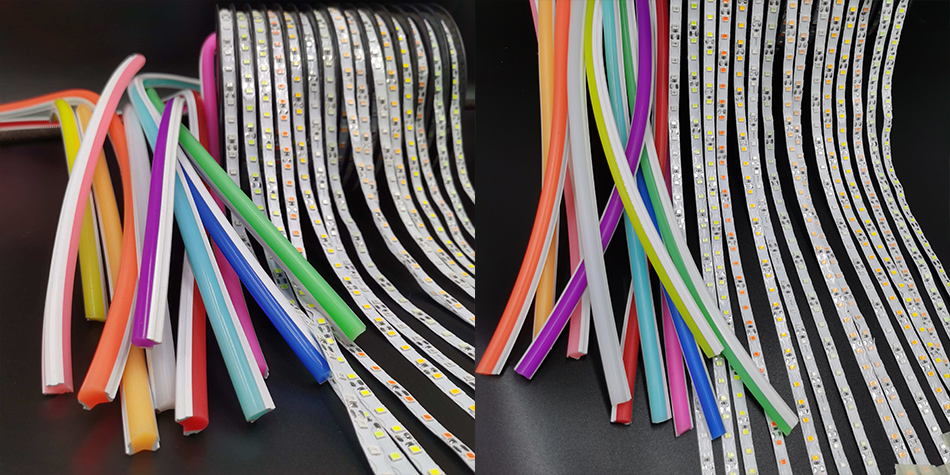

The outer layer of saltwater-resistant silicone neon strips for boats is made from specialized, high-grade silicone. This silicone is formulated with unique properties that provide an excellent barrier against saltwater corrosion. It has a dense molecular structure that prevents salt ions from penetrating and damaging the internal components of the strips. The silicone casing is highly flexible, allowing it to be easily installed on various curved and irregular surfaces commonly found on boats, such as the hull, deck edges, and cabin interiors.

The manufacturing process of the silicone casing involves advanced techniques to ensure a seamless and durable enclosure. It is resistant to the abrasive action of wind-driven salt spray and the constant movement and vibrations experienced during boat operation. Additionally, the silicone can withstand a wide range of temperatures, from the freezing cold of winter to the intense heat of summer, ensuring consistent performance in all maritime climates.

The LED Lighting Components

At the heart of these neon strips are carefully selected LED chips. These LEDs are specifically chosen for their ability to operate reliably in the harsh marine environment. They are designed to resist the harmful effects of moisture, salt, and temperature fluctuations, which can cause premature failure in ordinary LED components. The LEDs offer high energy efficiency, consuming minimal power while delivering bright and consistent illumination, which is crucial for boats where power resources may be limited.

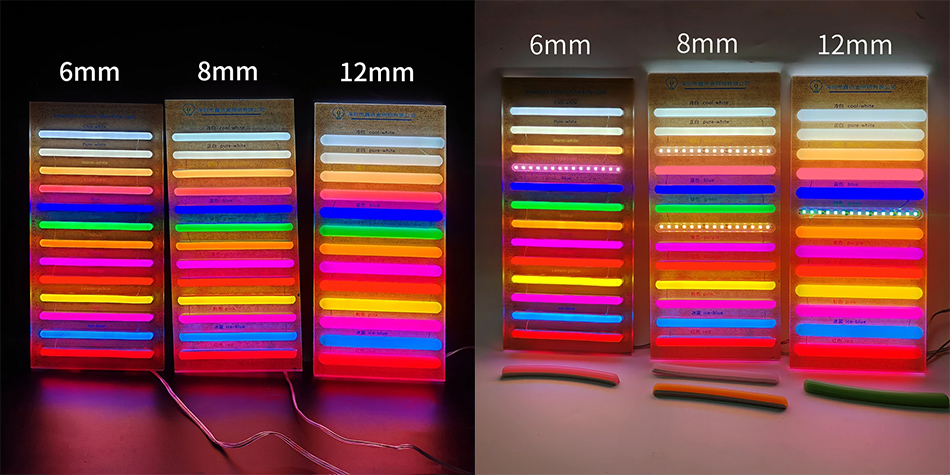

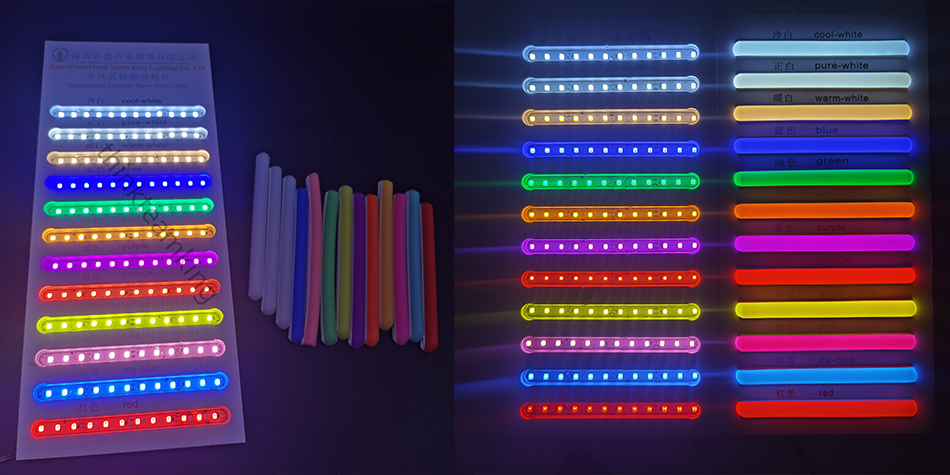

Moreover, the LEDs in saltwater-resistant silicone neon strips for boats come in a variety of colors and can support different lighting effects. Whether it's a warm white for creating a cozy cabin atmosphere or vibrant colors for decorative purposes and navigation lighting, these LEDs can meet diverse lighting needs on boats.

Sealing and Corrosion-Resistant Mechanisms

To achieve saltwater resistance, these neon strips incorporate advanced sealing and corrosion-resistant mechanisms. All joints, connections, and openings within the strip are meticulously sealed to prevent saltwater ingress. Specialized waterproof and corrosion-resistant connectors are used to link different sections of the strips, ensuring a secure and watertight connection.

In addition, the internal circuitry and electrical components are coated with protective layers that resist the corrosive effects of salt. These layers act as a shield, preventing salt from coming into contact with sensitive parts and reducing the risk of electrical failures. The combination of these sealing and protective measures makes the neon strips highly reliable in the challenging marine environment.

Key Features and Benefits of Saltwater-Resistant Silicone Neon Strips for Boats

Exceptional Saltwater Resistance

The most prominent feature of these neon strips is their outstanding saltwater resistance. They can withstand continuous exposure to saltwater, whether it's from waves splashing onto the deck, salt spray in the air, or accidental submersion. This resistance ensures that the strips maintain their functionality and appearance over time, without succumbing to the corrosive effects that can quickly damage ordinary lighting solutions in marine settings.

The ability to resist saltwater corrosion significantly extends the lifespan of the neon strips, reducing the frequency of replacements and maintenance, and ultimately saving boat owners time and money.

Durability and Long-Term Reliability

Combining the robust silicone casing and well-protected LED components, saltwater-resistant silicone neon strips for boats offer exceptional durability. They can endure the rigors of boat operation, including vibrations, impacts, and the constant movement of the vessel on the water. The strips are also resistant to UV radiation, which is prevalent in marine environments and can cause materials to degrade over time.

Their long-term reliability means that boat owners can rely on these strips to provide consistent lighting, enhancing safety and functionality on the boat. Whether it's for illuminating the deck at night or highlighting important navigation areas, the strips will perform reliably throughout their lifespan.

Energy Efficiency

Energy efficiency is a crucial benefit of saltwater-resistant silicone neon strips for boats. With limited power sources on boats, such as batteries or small generators, reducing energy consumption is essential. These LED-based strips consume far less power compared to traditional lighting options, allowing boat owners to extend the operation time of their electrical systems without overloading the power supply.

The reduced energy consumption not only saves on fuel costs (if a generator is used) but also helps to preserve the battery life, ensuring that there is enough power available for other essential functions on the boat.

Aesthetic Enhancement

Beyond functionality, saltwater-resistant silicone neon strips can greatly enhance the aesthetic appeal of boats. They can be used to create various lighting effects, adding a touch of elegance and style to the vessel's interior and exterior. For example, they can be installed along the gunwales to create a sleek and modern look, or inside the cabin to provide a warm and inviting ambiance.

The ability to choose from different colors and lighting patterns allows boat owners to customize the appearance of their boats according to their personal preferences and the occasion. Whether it's a luxurious yacht or a practical fishing boat, these neon strips can transform the visual appeal of the vessel, making it more attractive both during the day and at night.

Applications of Saltwater-Resistant Silicone Neon Strips on Boats

Interior Lighting

Inside the boat cabin, saltwater-resistant silicone neon strips are used for a variety of lighting purposes. They can be installed under cabinets, along the edges of ceilings, or around windows to provide ambient lighting. This soft and diffused illumination creates a comfortable and cozy living space for passengers and crew, especially during long voyages.

In the galley, the strips can be used to illuminate work surfaces, making it easier to prepare meals. They can also be installed inside storage compartments to help locate items quickly. For the navigation area, the neon strips can be used to backlight instruments and controls, ensuring clear visibility in low-light conditions without causing glare.

Exterior Lighting

On the exterior of boats, these neon strips have numerous applications. They are commonly used to line the edges of decks, providing safety lighting and enhancing the overall appearance of the vessel. The strips can also be installed around the perimeter of the hull, creating a striking visual effect, especially at night.

For boats used for fishing, the neon strips can be used to illuminate the fishing area, attracting fish and making it easier for fishermen to see their equipment and the catch. In addition, the strips can be used for decorative purposes on yachts, highlighting architectural features and creating a luxurious atmosphere for guests.

Navigation and Signaling Lighting

Navigation and signaling are critical functions on boats, and saltwater-resistant silicone neon strips play a role in this aspect as well. They can be used to create navigation lights that meet international maritime regulations. For example, red, green, and white strips can be installed in specific locations on the boat to indicate the port, starboard, and stern, respectively.

These strips can also be used for signaling purposes, such as flashing lights to indicate distress or to communicate with other vessels. Their bright and consistent illumination ensures that the signals are clearly visible from a distance, enhancing safety on the water.

Underwater Lighting

Some boats, especially yachts and diving boats, utilize saltwater-resistant silicone neon strips for underwater lighting. These strips are designed to be fully waterproof and can be installed on the hull of the boat below the waterline. Underwater lighting serves multiple purposes, such as attracting marine life for diving or fishing, enhancing the visual appeal of the boat when docked, and providing illumination for underwater inspections.

The different colors of the neon strips can create unique underwater lighting effects, adding an element of beauty and functionality to the boat's underwater presence.

Installation Considerations for Saltwater-Resistant Silicone Neon Strips on Boats

Surface Preparation

Before installing the neon strips on a boat, proper surface preparation is essential. The surface where the strips will be attached should be clean, dry, and free of any grease, dirt, or old adhesive residues. Marine surfaces, especially those exposed to the elements, may accumulate salt deposits, grime, and barnacles over time, which can affect the adhesion of the strips.

If the surface is rough or uneven, it may need to be sanded or smoothed to ensure a proper bond. In some cases, a primer may be applied to enhance the adhesion of the strips, especially on surfaces made of certain materials like fiberglass or metal.

Electrical Connection

Connecting the saltwater-resistant silicone neon strips to the boat's electrical system requires careful attention. First, it's important to ensure that the power source is compatible with the strips and that the electrical connections are secure. Boat electrical systems can be complex, and any loose or faulty connections can lead to electrical failures or even pose a safety hazard.

The wiring should be routed in a way that protects it from damage, such as being pinched, abraded, or exposed to saltwater. It's advisable to use marine-grade wiring and connectors that are resistant to corrosion and can withstand the harsh marine environment. In some cases, additional protection, such as conduit or cable glands, may be used to safeguard the wiring.

Mounting and Securing the Strips

There are different methods for mounting and securing saltwater-resistant silicone neon strips on boats. Some strips come with adhesive backing, which can be used for quick and easy installation on smooth surfaces. However, in the marine environment, where vibration and movement are common, it may be necessary to use additional mounting accessories, such as clips or screws, to ensure the strips remain firmly in place.

When using clips or screws, care should be taken not to damage the silicone casing or the internal components of the strips. The strips should be mounted in a way that allows for proper heat dissipation, as excessive heat can affect the performance and lifespan of the LEDs.

Maintenance and Troubleshooting of Saltwater-Resistant Silicone Neon Strips on Boats

Regular Inspection

Regular inspection of the neon strips is crucial to ensure their continued optimal performance. Boat owners or crew should periodically check the strips for any signs of damage, such as cracks in the silicone casing, loose connections, or a decrease in light output. Any damage to the silicone should be addressed promptly, as it can compromise the saltwater resistance of the strips.

Inspecting the electrical connections for signs of corrosion or looseness is also important. In a marine environment, saltwater can cause corrosion over time, which can affect the electrical conductivity. If any issues are detected, they should be resolved immediately to prevent further problems.

Cleaning

Cleaning the saltwater-resistant silicone neon strips is necessary to maintain their appearance and performance. A soft, damp cloth can be used to gently wipe away any salt deposits, dirt, or grime that may have accumulated on the surface of the silicone. Avoid using harsh chemicals or abrasive cleaners, as they can damage the silicone and affect the light transmission.

For underwater-installed strips, cleaning may require more specialized equipment, such as underwater brushes or divers, to remove any marine growth or debris that may have attached to the strips. Regular cleaning helps to ensure that the strips continue to provide bright and consistent illumination.

Troubleshooting Common Issues

If the saltwater-resistant silicone neon strips are not working properly, there are several common issues to check. First, verify the electrical connection. Ensure that the power source is providing the correct voltage and that all connections are secure. A loose connection can cause the strips to flicker or not turn on at all.

If the electrical connection is fine, check for any physical damage to the strips. A damaged LED chip or a break in the wiring can also result in non-functioning lights. In some cases, if only a section of the strip is not working, it may be possible to isolate and repair the problem. However, if the entire strip is malfunctioning, it may need to be replaced. Refer to the manufacturer's troubleshooting guide for specific instructions on resolving these issues.

Trends and Future Developments in Saltwater-Resistant Silicone Neon Strips for Boats

Integration with Smart Marine Systems

The future of saltwater-resistant silicone neon strips for boats is likely to see increased integration with smart marine systems. Smart lighting technology allows for remote control and monitoring of the strips using a smartphone app, a boat's onboard control system, or other smart devices. This enables users to adjust the brightness, color, and lighting patterns of the strips from anywhere on the boat, providing greater convenience and flexibility.

Smart lighting systems can also be programmed to respond to various sensors, such as motion sensors or ambient light sensors. For example, the strips can be set to turn on automatically when someone enters a cabin or to adjust their brightness based on the natural light available, further enhancing energy efficiency and user experience.

Advancements in Materials and Technology

As technology continues to evolve, we can expect significant advancements in both silicone and LED technologies for saltwater-resistant neon strips. Newer silicone materials may offer even higher levels of saltwater resistance, improved flexibility, and better protection against extreme temperatures. These advancements will make the strips even more durable and reliable, capable of withstanding the harshest marine conditions.

In terms of LED technology, there may be developments in LED chips that offer higher brightness levels, better color rendering, and improved energy efficiency. This will allow for more effective and visually appealing lighting on boats while consuming even less power.

Expansion of Applications

The applications of saltwater-resistant silicone neon strips in the marine industry are likely to expand in the future. With the growing popularity of sustainable and eco-friendly practices, these strips may be used in more innovative ways to support environmental initiatives. For example, they could be integrated with solar-powered systems on boats, providing a complete and sustainable lighting solution.

In addition, as the design and functionality of boats continue to evolve, the neon strips may be used in new and creative ways to enhance the overall user experience. This could include using the strips for immersive lighting in onboard entertainment areas or for creating unique lighting displays during marine events and festivals.

In conclusion, saltwater-resistant silicone neon strips for boats are an essential and versatile lighting solution for the maritime industry. Their ability to withstand the harsh marine environment, combined with their energy efficiency, durability, and aesthetic appeal, makes them a valuable asset for boat owners and operators. As technology continues to advance, these strips are set to play an even more significant role in the future of marine lighting, with increased integration, technological advancements, and expanded applications on the horizon.