Time:2025-06-26

In the vast and unpredictable world of outdoor lighting, the need for a robust and reliable solution is paramount, especially when faced with harsh weather conditions. Harsh weather, ranging from intense sunlight and driving rain to freezing temperatures and blustery winds, can pose significant challenges to the performance and longevity of traditional lighting systems. This is where heavy - duty silicone neon strips come into play, offering a durable and efficient lighting alternative that can withstand the harshest of outdoor environments.

The Challenges of Harsh Weather on Outdoor Lighting

Extreme Temperatures

Temperature fluctuations are a common feature of harsh weather conditions. In regions with extreme cold, such as polar areas or high - altitude mountainous regions, temperatures can drop well below freezing. These frigid temperatures can cause traditional lighting materials to become brittle, leading to cracks and breakages in components like plastic casings or glass tubes. On the other hand, in hot and arid climates, high temperatures can accelerate the degradation of materials, reduce the efficiency of electrical components, and even cause premature failure of the lighting system.

Moisture and Water Exposure

Rain, snow, and high humidity are other elements of harsh weather that can wreak havoc on outdoor lighting. Water ingress can short - circuit electrical connections, corrode metal parts, and damage sensitive electronic components. Even in areas with infrequent but heavy rainfall, the sudden exposure to large amounts of water can overwhelm the protective measures of standard lighting fixtures. Additionally, the constant presence of moisture in the air, as in coastal regions, can lead to the formation of rust and mold, further deteriorating the lighting system over time.

UV Radiation

The sun's ultraviolet (UV) radiation is a persistent threat to outdoor lighting, particularly in sunny regions. Prolonged exposure to UV rays can cause materials to fade, discolor, and become more brittle. Plastics and rubbers used in traditional lighting products are especially vulnerable to UV degradation, which can not only affect the aesthetic appearance of the lighting but also compromise its structural integrity and performance.

Wind and Physical Stress

Strong winds are another characteristic of harsh weather. In areas prone to storms or high - velocity winds, outdoor lighting fixtures are at risk of being knocked around, causing physical damage to the components. The force of the wind can also dislodge fixtures from their mounting points, leading to safety hazards. Additionally, in regions with heavy snowfall, the weight of accumulated snow on lighting fixtures can put additional stress, potentially causing them to bend, break, or collapse.

The Technology Behind Heavy - Duty Silicone Neon Strips

Silicone Material Properties

The use of high - quality silicone in heavy - duty neon strips is the cornerstone of their ability to withstand harsh weather. Silicone is a synthetic polymer with unique properties that make it ideal for outdoor applications. It has excellent flexibility, which allows the neon strips to be bent and shaped to fit various installation requirements without cracking or breaking. This flexibility also enables the strips to absorb the physical stress caused by wind and temperature changes, reducing the risk of damage.

Moreover, silicone has a high resistance to temperature extremes. It can maintain its elasticity and integrity in both extremely cold and hot conditions. In freezing temperatures, silicone does not become brittle like many other materials, ensuring that the neon strips remain functional. In high - temperature environments, silicone does not soften or deform easily, preserving the shape and performance of the strips.

Waterproof and Moisture - Resistant Design

Heavy - duty silicone neon strips are engineered to be highly waterproof and moisture - resistant. The silicone casing completely encapsulates the internal components, including the LEDs and electrical circuitry, creating a watertight seal. This seal prevents water from entering the strip, even in heavy rain or when submerged in water for short periods. Additionally, the silicone material is impermeable to moisture, preventing the formation of condensation inside the strip, which could otherwise damage the electrical components.

To further enhance their moisture resistance, these neon strips often feature sealed connectors and junctions. Specialized waterproof connectors are used to join multiple strips together or to connect the strip to the power supply. These connectors are designed to maintain a watertight connection, even when exposed to water, ensuring the continuous operation of the lighting system in wet conditions.

UV - Stabilized Construction

To combat the damaging effects of UV radiation, heavy - duty silicone neon strips are typically UV - stabilized. Manufacturers incorporate UV - resistant additives into the silicone material during the production process. These additives work by absorbing UV rays and converting them into heat, which is then dissipated harmlessly. This process prevents the UV rays from breaking down the chemical bonds in the silicone, thus preserving its physical and chemical properties. As a result, the neon strips can maintain their color, flexibility, and durability over long periods of exposure to sunlight, making them suitable for outdoor use in sunny regions.

Key Features of Heavy - Duty Silicone Neon Strips for Harsh Weather

Exceptional Durability

The combination of high - quality silicone material, waterproof design, and UV - stabilization gives heavy - duty silicone neon strips exceptional durability. They can withstand years of exposure to harsh weather conditions without significant degradation. The flexible silicone casing protects the internal components from physical damage, while the waterproof and UV - resistant features ensure that the strip remains functional and visually appealing over time. This durability means that users can rely on these neon strips for long - term outdoor lighting applications, reducing the need for frequent replacements and maintenance.

Versatile Design

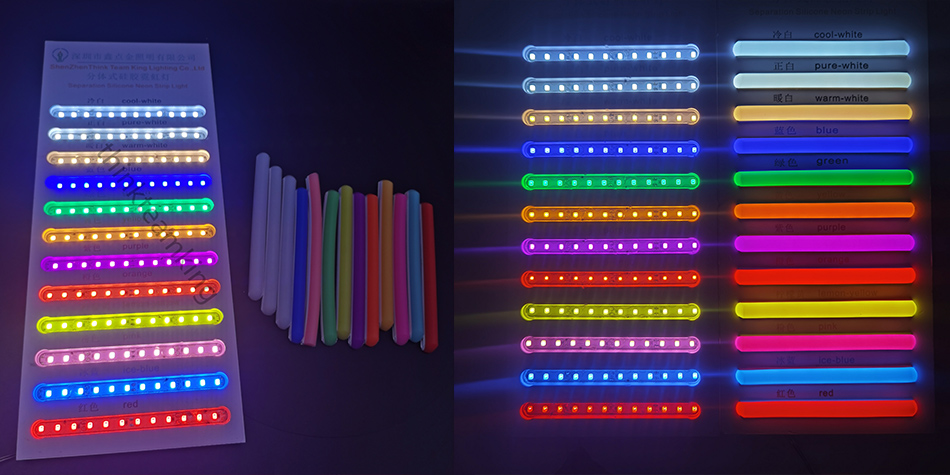

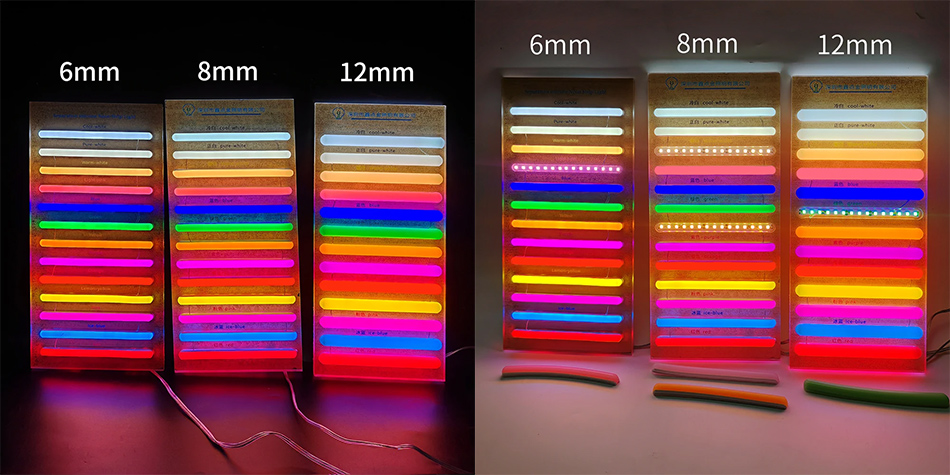

Despite their heavy - duty construction, these neon strips offer great design versatility. The flexibility of the silicone allows the strips to be easily installed in a variety of shapes and patterns. They can be bent around corners, curved along irregular surfaces, or shaped to create custom lighting designs. This makes them suitable for a wide range of outdoor applications, from highlighting the architectural features of a building to creating decorative lighting effects in a garden. The wide range of colors available, thanks to the use of LED technology, also enables users to customize the lighting to match the aesthetic of their outdoor space.

Energy Efficiency

Heavy - duty silicone neon strips typically utilize LED technology, which is known for its energy - efficiency. LEDs consume significantly less power compared to traditional lighting sources, such as incandescent bulbs. This not only reduces electricity costs for users but also makes the neon strips an environmentally friendly choice. The long lifespan of LEDs also means that the strips require less frequent replacement, further contributing to energy savings and reducing the environmental impact associated with manufacturing and disposal.

Safety

Safety is a crucial aspect of these neon strips. The waterproof and moisture - resistant design eliminates the risk of electrical shocks caused by water ingress, making them safe to use in wet outdoor environments. Additionally, the low - voltage operation of most LED - based neon strips reduces the potential for electrical hazards. The durable construction of the strips also ensures that they can withstand physical stress without breaking or posing a safety risk to people or property.

Applications of Heavy - Duty Silicone Neon Strips in Harsh Weather Conditions

Outdoor Architectural Lighting

In outdoor architectural applications, heavy - duty silicone neon strips are used to enhance the visual appeal of buildings. They can be installed along the edges of roofs, around windows, or to highlight unique architectural details such as columns, arches, or facades. In areas with harsh weather, such as coastal regions or high - altitude locations, these neon strips can withstand the elements and continue to provide attractive lighting for the building. For example, in a beachfront hotel, the neon strips can be used to outline the building's balconies and walkways, creating a welcoming and visually appealing atmosphere even in the face of salt - laden sea breezes, strong winds, and intense sunlight.

Landscape and Garden Lighting

Landscape and garden designers often turn to heavy - duty silicone neon strips to create beautiful and functional outdoor lighting in harsh weather conditions. These strips can be used to line garden pathways, providing illumination and safety for pedestrians. They can also be used to highlight garden features such as trees, shrubs, water features, and sculptures. In regions with extreme temperatures, heavy snowfall, or frequent rain, the durable nature of the neon strips ensures that they can withstand the weather and continue to enhance the beauty of the garden. For instance, in a mountainous garden, the neon strips can be used to light up the steps leading to a 观景台,remaining operational even during heavy snowstorms and cold winters.

Commercial and Industrial Signage

For commercial and industrial establishments, outdoor signage is an important marketing and safety tool. Heavy - duty silicone neon strips are ideal for creating eye - catching signs that can withstand harsh weather. Whether it's a large - scale billboard on the side of a highway or a small storefront sign in a busy street, these neon strips can attract attention even in adverse weather conditions. The durability of the strips ensures that the signage remains visible and functional over time, reducing the need for frequent repairs or replacements. In an industrial area with high winds and exposure to dust and moisture, the neon strips can be used to create safety signs and directional indicators that are reliable and long - lasting.

Outdoor Event and Entertainment Venues

Outdoor event and entertainment venues, such as concert stages, festival grounds, and amusement parks, require lighting systems that can withstand the rigors of constant use and harsh weather. Heavy - duty silicone neon strips can be used to create dynamic and engaging lighting effects in these venues. They can be used to light up stages, create visual backdrops, and add a festive atmosphere to the event. In outdoor concert venues, for example, the neon strips can be used to outline the stage, create colorful lighting patterns, and enhance the overall experience for the audience, even in the face of rain, wind, or extreme temperatures.

Considerations When Choosing Heavy - Duty Silicone Neon Strips

Weather Resistance Features

When selecting heavy - duty silicone neon strips, it's essential to consider their weather resistance features. Look for strips that are specifically designed to withstand the particular harsh weather conditions of your area. For example, if you live in a region with high humidity and frequent rain, choose strips with excellent waterproof and moisture - resistant properties. In sunny areas, prioritize strips with high UV - resistance. Check the product specifications and look for certifications or testing results that demonstrate the strip's ability to withstand extreme temperatures, water exposure, and UV radiation.

Color and Lighting Effects

The color and lighting effects of the neon strips are important considerations. Think about the mood and atmosphere you want to create in your outdoor space. Consider the color temperature, hue, and the ability of the strips to produce different lighting effects such as dimming, color - changing, or flashing. Whether you want a soft, warm glow for a relaxing outdoor setting or bright, vibrant colors for a more energetic atmosphere, choose strips that can meet your specific design requirements.

Installation and Compatibility

Evaluate the ease of installation of the neon strips. Some strips may come with adhesive backing for simple surface mounting, while others may require more complex installation methods using mounting clips or screws. Consider the compatibility of the strips with your existing electrical setup. Ensure that the power requirements of the strips match your available electrical infrastructure, and that any control systems, such as dimmers or smart lighting controllers, are compatible with the strips.

6.4 Quality and Brand Reputation

Investing in high - quality heavy - duty silicone neon strips from a reputable brand is crucial. Look for products that are made from high - grade silicone materials and have a proven track record of performance in harsh weather conditions. Read customer reviews and testimonials to get an idea of the product's reliability and durability. A well - known brand is more likely to offer a comprehensive warranty and good customer support, providing you with peace of mind in case of any issues with the product.

Installation and Maintenance of Heavy - Duty Silicone Neon Strips

Installation Process

The installation process for heavy - duty silicone neon strips depends on the specific product and application. For surface - mounted installations, start by cleaning the surface thoroughly to ensure good adhesion. If using adhesive - backed strips, carefully remove the protective backing and apply the strip to the surface, pressing firmly to ensure a secure bond. For more complex installations, such as those involving multiple strips or custom - shaped designs, follow the manufacturer's detailed installation instructions. This may involve using mounting hardware, making electrical connections, and ensuring proper waterproofing of all connections. When making electrical connections, it's important to follow safety guidelines and, if necessary, consult a professional electrician.

Maintenance Requirements

Maintenance of heavy - duty silicone neon strips is relatively straightforward. Periodically inspect the strips for any signs of damage, such as cracks in the silicone casing, loose connections, or a decrease in light output. Clean the strips gently with a soft, dry cloth to remove any dust, dirt, or debris that may have accumulated. Avoid using harsh chemicals or abrasive cleaners, as these can damage the silicone and reduce the strip's weather resistance. In case of any issues, refer to the manufacturer's troubleshooting guide or contact their customer support for assistance. Regular maintenance will help ensure the longevity and optimal performance of the neon strips in harsh weather conditions.

Trends and Future Developments in Heavy - Duty Silicone Neon Strips

Smart Lighting Integration

One of the emerging trends in heavy - duty silicone neon strips is the integration of smart lighting technology. Smart neon strips can be controlled remotely using smartphones, tablets, or voice - activated assistants. This allows users to adjust the color, brightness, and lighting effects of the strips, create custom lighting scenes, and even set schedules for the lights to turn on and off. Smart integration also enables energy - saving features, such as automatically dimming the lights during less - busy hours or when natural light is sufficient. In harsh weather conditions, smart lighting systems can also be programmed to adjust the lighting based on environmental factors, such as reducing the brightness during a snowstorm to avoid glare.

Advancements in Material Science

Ongoing research and development in material science are likely to lead to further advancements in heavy - duty silicone neon strips. Newer silicone formulations with even higher resistance to extreme temperatures, moisture, and UV radiation may be developed. Additionally, the use of innovative additives and manufacturing techniques could enhance the durability and performance of the strips. For example, the incorporation of nanomaterials into the silicone could improve its strength and flexibility, making the strips even more resistant to physical stress.

Sustainable and Eco - Friendly Solutions

With the increasing focus on sustainability, there is a growing demand for eco - friendly outdoor lighting solutions. Manufacturers are likely to develop heavy - duty silicone neon strips that use more sustainable materials, such as recycled silicone or energy - efficient LEDs with reduced environmental impact. These sustainable solutions will not only meet the needs of environmentally conscious consumers but also contribute to a more sustainable future for outdoor lighting in harsh weather conditions.

In conclusion, heavy - duty silicone neon strips offer a reliable and durable lighting solution for outdoor applications in harsh weather conditions. Their ability to withstand extreme temperatures, moisture, UV radiation, and physical stress, combined with their energy - efficiency, design versatility, and safety features, makes them an ideal choice for a wide range of outdoor projects. By carefully considering the key factors when choosing and installing these strips and staying updated on the latest trends and developments, users can enjoy long - lasting and effective outdoor illumination even in the most challenging weather environments.