Time:2025-06-28

In the specialized domain of lighting solutions, submersible waterproof silicone neon strip lights have carved out a unique niche. These lights are designed to thrive in the most challenging wet and underwater conditions, offering a blend of durability, functionality, and aesthetic appeal. From enhancing the allure of underwater landscapes to providing reliable lighting in humid industrial settings, they have become indispensable in various applications. This article delves into the details of submersible waterproof silicone neon strip lights, exploring their construction, features, applications, installation, and future trends.

The Construction and Technology of Submersible Waterproof Silicone Neon Strip Lights

The Silicone Encapsulation

The outer layer of submersible waterproof silicone neon strip lights is made from high - grade silicone, a material specifically chosen for its exceptional water - resistant properties. This silicone casing forms a tight seal around the internal components, preventing water from seeping in even when the lights are fully submerged. The silicone is not only waterproof but also highly flexible, allowing the strips to be bent and shaped to fit a variety of surfaces and spaces.

The manufacturing process of the silicone casing involves precise molding techniques to ensure a seamless and durable enclosure. It is resistant to the corrosive effects of water, including saltwater, which makes these lights suitable for marine applications. Additionally, the silicone can withstand extreme temperature fluctuations, ensuring that the lights remain functional in both freezing cold and sweltering hot aquatic environments.

The LED Lighting Components

Inside the silicone casing, the LED chips are the heart of the lighting system. These LEDs are carefully selected for their ability to operate efficiently in wet conditions. They are designed to have excellent resistance to moisture - related issues, such as short - circuits and corrosion of electrical contacts.

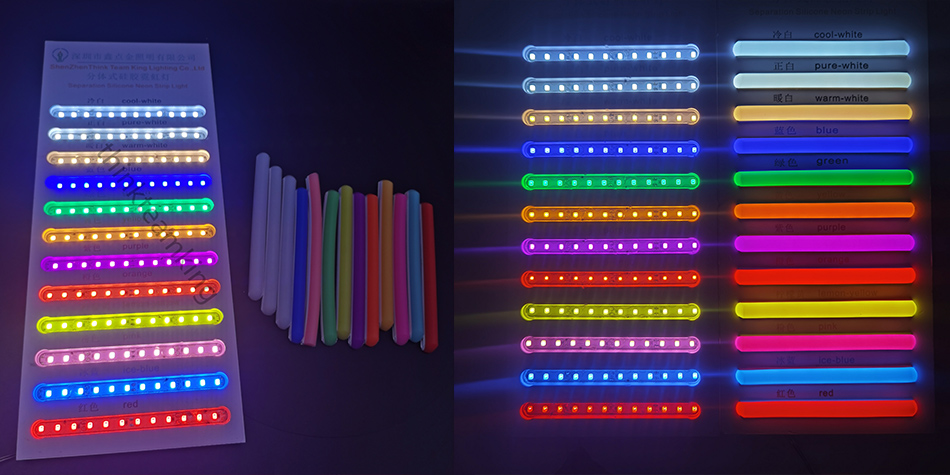

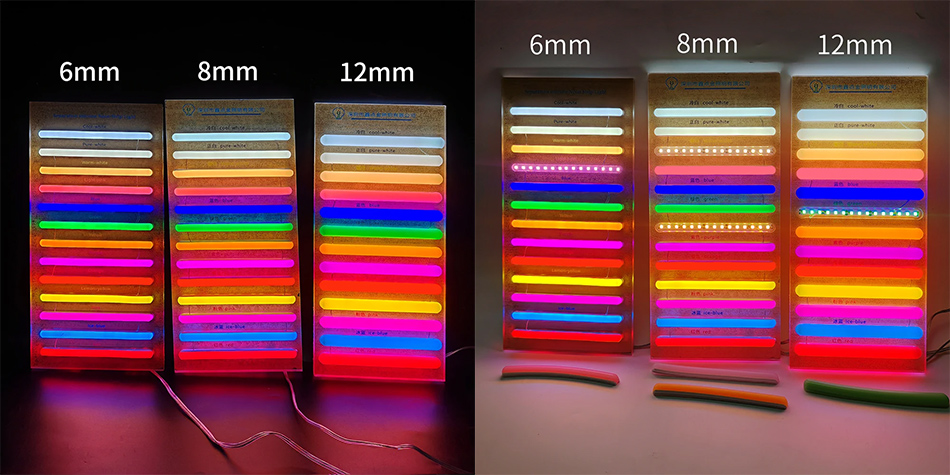

The LEDs used in submersible waterproof silicone neon strip lights offer the same advantages as their non - submersible counterparts, including high energy efficiency, long lifespan, and a wide range of color options. Whether it's a single - color illumination for a specific effect or a multi - colored display using RGB technology, these LEDs can deliver vibrant and consistent lighting, even when underwater.

Sealing and Waterproofing Mechanisms

To ensure complete water resistance, submersible waterproof silicone neon strip lights incorporate advanced sealing and waterproofing mechanisms. The joints and connections within the strip, such as where the LED chips are attached to the circuit board and where multiple strips are joined together, are meticulously sealed.

Specialized waterproof connectors are used to link different sections of the strip lights. These connectors are designed to create a watertight connection, preventing any water ingress. In some cases, additional layers of sealant or gaskets may be used at critical points to further enhance the waterproofing, ensuring that the lights can be safely used in deep - water applications or in areas with high water pressure.

Key Features and Benefits of Submersible Waterproof Silicone Neon Strip Lights

Unmatched Waterproof Performance

The most obvious and crucial feature of these lights is their submersible and waterproof nature. They can be fully immersed in water for extended periods without any damage to the internal components. This makes them ideal for a wide range of applications where exposure to water is inevitable, such as underwater aquariums, fountains, swimming pools, and marine vessels.

The ability to withstand water not only ensures the functionality of the lights but also their longevity. Unlike regular lighting solutions that would quickly fail when exposed to water, submersible waterproof silicone neon strip lights can continue to operate reliably, reducing the need for frequent replacements and maintenance in wet environments.

Durability and Long - Term Reliability

In addition to their waterproofing, these lights are highly durable. The combination of the robust silicone casing and the well - protected LED components allows them to endure harsh conditions. They can resist physical impacts, abrasion, and the constant movement and vibrations often found in underwater or wet settings.

Whether it's the strong currents in a river, the constant splashing in a fountain, or the rough handling during installation and maintenance, submersible waterproof silicone neon strip lights can withstand these challenges. Their long - term reliability makes them a cost - effective choice for applications where lighting needs to be consistent and trouble - free over an extended period.

Energy Efficiency and Cost Savings

Despite their specialized design for wet environments, submersible waterproof silicone neon strip lights are energy - efficient. The LED technology they employ consumes significantly less power compared to traditional lighting sources. This energy efficiency not only helps in reducing electricity bills but also makes them more environmentally friendly.

In large - scale applications, such as commercial aquariums or public fountains, the cumulative energy savings from using these energy - efficient lights can be substantial. The lower energy consumption also means less heat generation, which is beneficial in underwater environments where excessive heat can affect the surrounding ecosystem or the integrity of the lighting system itself.

Aesthetic Versatility

Submersible waterproof silicone neon strip lights offer a high degree of aesthetic versatility. With a wide range of colors and lighting effects available, they can be used to create stunning visual displays. In underwater settings, they can transform a simple aquarium into a mesmerizing underwater world, highlighting the beauty of marine life and the aquarium's architecture.

In fountains and water features, these lights can be used to create dynamic and colorful light shows, synchronized with music or other elements to enhance the overall experience. Their ability to produce different lighting effects, such as static, flashing, fading, and color - changing, allows for endless creative possibilities in both functional and decorative applications.

Applications of Submersible Waterproof Silicone Neon Strip Lights

Aquariums and Underwater Exhibits

In aquariums, submersible waterproof silicone neon strip lights are used to illuminate the underwater environment, providing a clear view of the marine life and enhancing the visual appeal of the exhibits. They can be installed along the edges of the aquarium, around rocks and coral formations, or hidden within the substrate to create a natural - looking lighting effect.

The different colors of the lights can be used to mimic the natural light conditions of the ocean at various depths or to highlight specific species of fish or plants. In large - scale public aquariums, these lights can also be used to create themed exhibits, such as a glowing underwater cave or a colorful coral reef, attracting visitors and providing an educational and immersive experience.

Fountains and Water Features

Fountains and water features are another popular application for submersible waterproof silicone neon strip lights. They can be placed at the base of the fountain, within the water jets, or around the perimeter of the water feature. The lights can be programmed to change colors and patterns, creating a captivating light show that is synchronized with the movement of the water.

In public parks, hotels, and commercial buildings, illuminated fountains with submersible lights add a touch of elegance and charm. They can also serve as a focal point for events and gatherings, providing a visually stunning backdrop. The waterproof nature of the lights ensures that they can operate safely in the constantly wet and splashing environment of fountains.

Marine and Aquatic Construction

In marine and aquatic construction projects, such as the construction of docks, piers, and underwater structures, submersible waterproof silicone neon strip lights are used for both functional and safety purposes. They can be installed along the edges of docks to provide illumination for boats during docking and undocking, especially at night.

These lights can also be used to mark underwater hazards or boundaries, making the waterways safer for navigation. In addition, they can be used to enhance the aesthetic appeal of marine structures, creating a more inviting and visually appealing waterfront environment.

Industrial and Wet Environment Settings

In industrial settings where there is a high level of moisture or water exposure, such as food processing plants, breweries, and water treatment facilities, submersible waterproof silicone neon strip lights are a reliable lighting solution. They can be used to illuminate work areas, corridors, and storage spaces, ensuring that employees have a clear view of their surroundings while working in wet conditions.

The durability and waterproof nature of these lights make them suitable for withstanding the harsh cleaning chemicals and frequent water - washing processes often found in these industrial environments. They can also be used in cold storage facilities, where they can operate effectively in low - temperature and humid conditions.

Installation Considerations for Submersible Waterproof Silicone Neon Strip Lights

Surface Preparation

Before installing submersible waterproof silicone neon strip lights, the surface where they will be placed needs to be properly prepared. In underwater applications, the surface should be free of debris, algae, and other contaminants that could affect the adhesion of the lights or the performance of the waterproof seals.

For surfaces in wet environments, such as the inside of a fountain or a pool, the surface should be clean and dry (as much as possible before submersion). Rough or uneven surfaces may require additional treatment, such as sanding or the application of a primer, to ensure a secure and watertight installation.

Electrical Connection

Connecting the submersible waterproof silicone neon strip lights to the electrical supply requires careful attention. Since these lights are designed for use in wet and potentially hazardous environments, the electrical connections must be made in accordance with strict safety standards.

A suitable waterproof power supply is essential, and it should be installed in a location that is protected from water ingress. The wiring between the power supply and the lights should be routed through waterproof conduits or sheaths to prevent any water from coming into contact with the electrical wires. All connections should be double - checked to ensure they are secure and waterproof, using specialized waterproof connectors and sealants.

Mounting and Securing the Lights

There are various methods for mounting and securing submersible waterproof silicone neon strip lights. Some strips come with adhesive backing that can be used to attach them to smooth surfaces. However, in underwater or high - movement environments, additional mechanical fasteners, such as clips or screws, may be required to ensure the lights remain in place.

When using clips or screws, care should be taken not to damage the silicone casing or the waterproof seals. The lights should be mounted in a way that allows for proper heat dissipation, as excessive heat can affect the performance and lifespan of the LEDs. In some cases, special mounting brackets or fixtures designed for underwater use may be necessary to ensure the stability and safety of the installation.

Maintenance and Troubleshooting of Submersible Waterproof Silicone Neon Strip Lights

Regular Inspection

Regular inspection is crucial to ensure the optimal performance of submersible waterproof silicone neon strip lights. In underwater applications, the lights should be inspected for any signs of damage to the silicone casing, such as cracks or tears, which could compromise the waterproof integrity. The electrical connections should also be checked for any signs of corrosion or looseness.

In wet environments, the lights should be inspected periodically for dirt, debris, or algae buildup that could block the light output or affect the performance of the lights. Any issues detected during the inspection should be addressed promptly to prevent further damage and ensure the continued reliability of the lighting system.

Cleaning

Cleaning submersible waterproof silicone neon strip lights is an important part of maintenance. In underwater settings, a soft brush or sponge can be used to gently remove any algae or debris that has accumulated on the surface of the lights. Avoid using harsh chemicals or abrasive cleaners, as they can damage the silicone casing.

For lights in wet environments, such as fountains or pools, a mild cleaning solution can be used to remove dirt and grime. After cleaning, the lights should be thoroughly rinsed with clean water to ensure that no cleaning residues remain. Regular cleaning not only helps to maintain the appearance of the lights but also ensures that they continue to provide optimal illumination.

Troubleshooting Common Issues

If the submersible waterproof silicone neon strip lights are not working properly, there are several common issues to check. First, verify the electrical connection. Ensure that the power supply is functioning correctly and that all connections are secure and waterproof. A loose or damaged connection can cause the lights to flicker, dim, or not turn on at all.

If the electrical connection is fine, check for any physical damage to the lights. A damaged LED chip or a break in the silicone casing can also result in non - functioning lights. In some cases, if only a section of the strip is not working, it may be possible to isolate and repair the problem. However, if the entire strip is malfunctioning, it may need to be replaced. Refer to the manufacturer's troubleshooting guide for specific instructions on resolving these issues.

Trends and Future Developments in Submersible Waterproof Silicone Neon Strip Lights

Smart Lighting Integration

The future of submersible waterproof silicone neon strip lights is likely to see increased integration with smart lighting technology. Smart submersible lights can be controlled remotely using a smartphone app, a tablet, or a central control system. This allows users to adjust the color, brightness, and lighting effects of the lights from a distance, providing greater convenience and flexibility.

Smart lighting systems can also be programmed to respond to various sensors, such as motion sensors or water level sensors. For example, the lights could automatically turn on when someone approaches a pool or fountain, or adjust their brightness based on the ambient light levels. This integration with smart technology will enhance the functionality and user experience of submersible waterproof silicone neon strip lights.

Advancements in Materials and Technology

As technology continues to evolve, we can expect significant advancements in the materials and technology used in submersible waterproof silicone neon strip lights. Newer silicone materials may offer even better waterproofing, durability, and flexibility. These materials could also be more resistant to the corrosive effects of different types of water, such as highly acidic or alkaline water.

In terms of LED technology, there may be developments in LED chips that offer higher brightness levels, better color rendering, and improved energy efficiency. These advancements will make submersible waterproof silicone neon strip lights more powerful, energy - saving, and visually appealing, further expanding their applications in various underwater and wet environments.

Sustainable and Eco - Friendly Solutions

With the growing focus on sustainability and environmental protection, there is a trend towards developing more sustainable and eco - friendly submersible waterproof silicone neon strip lights. This may involve the use of recycled materials in the production of the silicone casing and other components. Manufacturers may also focus on reducing the energy consumption of the lights even further, for example, by improving the efficiency of the power - conversion systems.

Some companies may explore the use of biodegradable or compostable materials in certain parts of the light construction, although this may be more challenging due to the need for durability in underwater and wet applications. Overall, the development of sustainable and eco - friendly solutions in submersible waterproof silicone neon strip lights aligns with the global push towards a more sustainable future.

In conclusion, submersible waterproof silicone neon strip lights have become an essential lighting solution for underwater and wet environments. Their unique combination of waterproof performance, durability, energy efficiency, and aesthetic versatility makes them suitable for a wide range of applications. As technology continues to advance, these lights are likely to become even more sophisticated and widely used, with exciting developments in smart integration, material advancements, and sustainability on the horizon.