Time:2025-06-21

In the dynamic realm of modern lighting, neon strip lights have emerged as a versatile and captivating lighting solution. These lights have transcended their traditional use in signage and have found their way into a wide array of applications, from enhancing the aesthetics of interior spaces to adding a touch of glamour to outdoor environments. This article delves deep into the world of neon strip lights, exploring their technology, manufacturing process, diverse applications, and the factors to consider when choosing them.

The Technology Behind Neon Strip Lights

Gas - Discharge Principles

Neon strip lights operate on the principle of gas - discharge. Inside the glass or silicone tube of the strip, a low - pressure gas, typically neon or a mixture of neon and other noble gases like argon, is sealed. When a high - voltage electrical current is applied across the electrodes at the ends of the tube, the gas atoms become ionized. The electrons in the ionized gas gain energy and then release this energy in the form of photons as they return to their ground state. In the case of neon, it emits a characteristic bright red - orange light. However, by using different gases or adding phosphor coatings to the inside of the tube, a wide spectrum of colors can be achieved. For example, argon mixed with mercury vapor produces a blue - white light, and phosphor - coated tubes can transform the ultraviolet light emitted by mercury vapor into various visible colors such as green, yellow, or pink.

LED Integration in Neon - Like Strips

In recent years, there has been a significant shift towards LED - based neon strip lights. These strips use light - emitting diodes (LEDs) to produce light instead of the traditional gas - discharge method. LEDs are semiconductor devices that emit light when an electric current passes through them. LED neon - like strips offer several advantages over traditional neon lights. They are more energy - efficient, consuming significantly less power while providing a similar or even brighter illumination. They also have a longer lifespan, are more durable as they are less prone to breakage compared to glass - tube neon lights, and can be easily controlled to produce different lighting effects such as dimming, color - changing, and flashing.

Manufacturing Process of Neon Strip Lights

Tube Preparation

For traditional neon strip lights, the process starts with the selection of high - quality glass tubes. These tubes are carefully cleaned and inspected for any defects. The tubes are then bent into the desired shapes, which can range from simple straight lines for basic installations to complex curves and custom designs for artistic or decorative purposes. This bending process requires skilled craftsmanship to ensure that the tubes maintain their integrity and the gas - discharge properties are not compromised. After bending, the tubes are fitted with electrodes at each end. These electrodes are typically made of materials such as tungsten or nickel, which can withstand the high - voltage electrical current and the chemical reactions that occur within the tube.

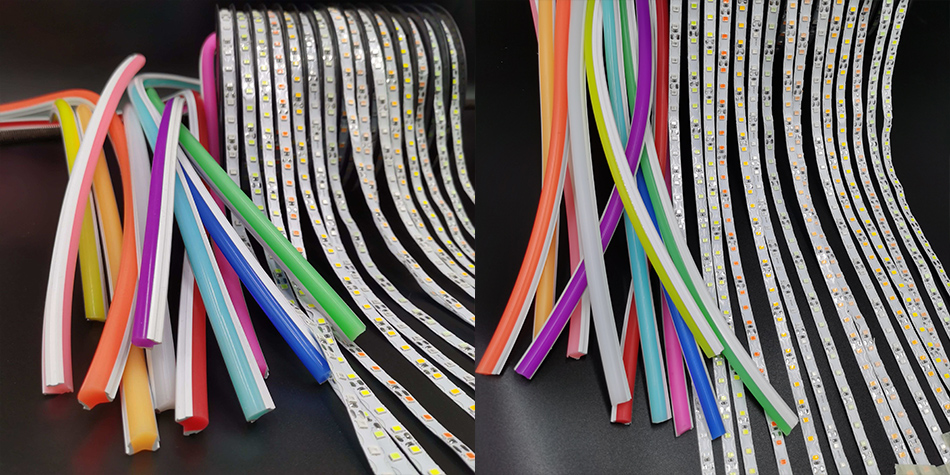

For LED - based neon strip lights, the process begins with the production of the circuit board. The circuit board is designed to carry the electrical current to the LEDs and is often made of flexible printed circuit board (PCB) material, which allows the strip to be flexible and bendable. The LEDs are then mounted onto the circuit board using surface - mount technology (SMT), which ensures a secure and reliable connection. Once the LEDs are mounted, the circuit board is encapsulated in a protective material, often silicone. Silicone is preferred for its flexibility, durability, and resistance to environmental factors such as moisture, UV rays, and temperature variations.

Gas Filling and Sealing

In the case of traditional neon strip lights, after the tube and electrode assembly is complete, the tube is evacuated to create a low - pressure environment. Specialized vacuum pumps are used to remove air and other impurities from the tube. Once the desired vacuum level is achieved, the appropriate gas or gas mixture is introduced into the tube. The gas is carefully measured and filled to the correct pressure to ensure optimal performance and consistent light output. After filling, the tube is sealed to prevent the gas from escaping. This sealing process is crucial as any leakage can cause the light to malfunction or have a reduced lifespan.

For LED - based neon strip lights, the focus is on the proper encapsulation of the circuit board and LEDs. The silicone encapsulation not only protects the electronic components from physical damage but also helps to diffuse the light evenly, creating a soft and consistent glow similar to traditional neon lights. The edges of the silicone - coated strip are carefully sealed to prevent moisture or dust from entering, which could potentially damage the LEDs or the circuit board.

Quality Control and Testing

Both traditional and LED - based neon strip lights undergo rigorous quality control and testing procedures before they are released into the market. Electrical tests are conducted to ensure that the lights operate at the correct voltage and current levels. For traditional neon lights, tests are also performed to check the gas - discharge properties, such as the stability of the light output and the color consistency. LED - based neon strip lights are tested for LED performance, including brightness, color accuracy, and color - rendering index (CRI). Mechanical tests are carried out to assess the durability and flexibility of the strips. They are bent, twisted, and subjected to various physical stresses to ensure that they can withstand normal handling and installation. Additionally, environmental tests are conducted to evaluate the strips' performance in different conditions, such as high and low temperatures, humidity, and exposure to UV rays. Only strips that pass all these comprehensive tests are approved for distribution.

Applications of Neon Strip Lights

Interior Decor and Design

Neon strip lights have become a popular choice for interior decorators and homeowners alike. In living rooms, they can be installed behind sofas, along the edges of shelves, or under cabinets to create a warm and inviting ambient light. The soft glow of the neon strips can add depth and dimension to the room, making it feel more spacious and comfortable. In bedrooms, these lights can be used to create a relaxing and romantic atmosphere. They can be placed behind the headboard, around mirrors, or under the bed, providing a gentle illumination that is perfect for reading or setting a mood. In kitchens, neon strip lights are ideal for under - cabinet lighting. They not only provide task lighting for food preparation but also add a modern and stylish touch to the kitchen design.

Commercial and Retail Spaces

In the commercial and retail sectors, neon strip lights play a crucial role in attracting customers and enhancing the shopping experience. In retail stores, they are used to create eye - catching window displays. The bright and colorful lights can draw the attention of passers - by and showcase products in an attractive way. Neon strip lights are also used to highlight product shelves inside the store, making it easier for customers to find what they are looking for. In restaurants and cafes, these lights are used to set the mood. They can be installed along the walls, around the bar area, or under the tables to create a cozy and inviting dining environment. In entertainment venues such as clubs and theaters, neon strip lights are used to create a dynamic and energetic atmosphere, enhancing the overall experience for the audience.

Architectural and Landscape Lighting

Architects and landscape designers often incorporate neon strip lights into their projects to enhance the visual appeal of buildings and outdoor spaces. In architecture, neon strip lights can be used to accentuate the unique features of a building's facade. They can be installed along the edges of roofs, eaves, windows, and doors, creating a striking nighttime presence. The soft, glowing lines of the neon strips can add depth and dimension to the building, making it stand out in the urban landscape. In landscape lighting, neon strip lights are used to illuminate pathways, gardens, and outdoor structures. They can be installed along the edges of walkways, around trees and shrubs, or under benches and pergolas, providing a safe and inviting outdoor environment. The flexibility of the neon strips allows for creative installations that can highlight the natural beauty of the landscape.

Advantages of Neon Strip Lights

Energy Efficiency

LED - based neon strip lights, in particular, are highly energy - efficient. LEDs convert a large percentage of the electrical energy they consume into light energy, as opposed to traditional incandescent or fluorescent lights, which also produce a significant amount of heat. This energy efficiency not only helps to reduce electricity bills but also makes neon strip lights an environmentally friendly lighting option. By consuming less power, they contribute to a lower carbon footprint and a more sustainable future.

Durability and Longevity

Both traditional and LED - based neon strip lights are designed to be durable. Traditional neon lights, with their sturdy glass tubes and well - constructed electrodes, can last for many years if properly installed and maintained. LED - based neon strip lights, on the other hand, have an even longer lifespan. LEDs are known for their long - lasting performance, and when encapsulated in silicone, they are protected from physical damage, moisture, and other environmental factors. This durability means that neon strip lights require less frequent replacement, reducing the overall cost of ownership.

Customization and Flexibility

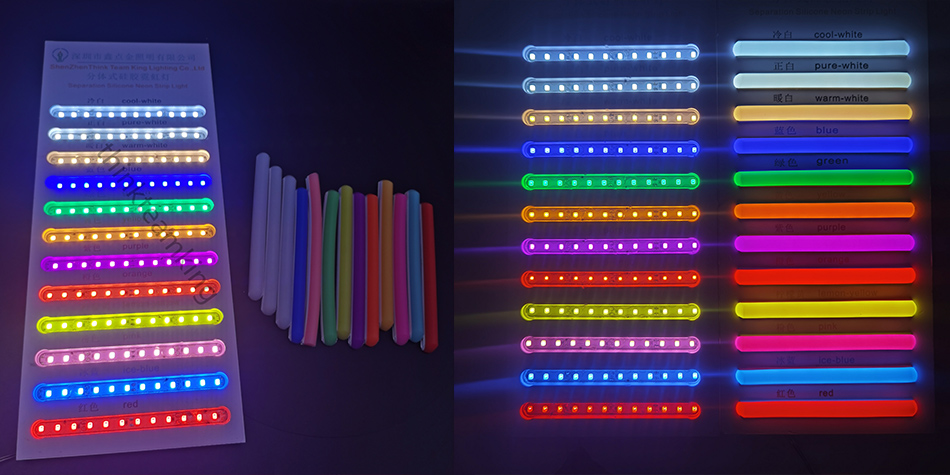

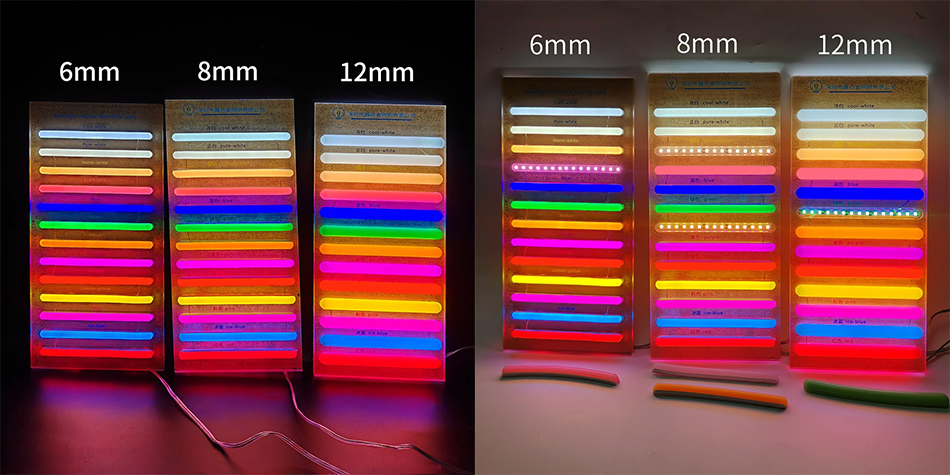

Neon strip lights offer a high degree of customization and flexibility. They are available in a wide range of colors, allowing users to choose the perfect color to match their decor or branding. Additionally, LED - based neon strip lights can be easily controlled to produce different lighting effects. They can be dimmed, set to change colors, or programmed to flash in various patterns. The flexibility of the strips also allows them to be bent and shaped to fit any surface or design requirement, making them suitable for both simple and complex installations.

Factors to Consider When Choosing Neon Strip Lights

Light Output and Color

When choosing neon strip lights, it is important to consider the desired light output and color. The brightness of the strips can vary, and it is essential to select a strip that provides sufficient illumination for the intended application. For example, for task lighting in a kitchen or workshop, a brighter strip may be required, while for ambient lighting in a living room or bedroom, a softer glow may be more appropriate. The color of the neon strip lights should also match the overall aesthetic of the space. Whether it's a bold and vibrant color for a commercial setting or a soft and subtle color for a residential interior, the color choice can significantly impact the mood and atmosphere of the area.

Power Requirements and Energy Consumption

Understanding the power requirements and energy consumption of neon strip lights is crucial, especially for large - scale installations or when aiming to reduce electricity costs. LED - based neon strip lights are generally more energy - efficient, but different models may still have varying power consumption levels. It is important to check the specifications of the strips and consider the overall power load on the electrical system. Additionally, if energy efficiency is a top priority, look for strips with high - efficiency LEDs and power - saving features such as dimming capabilities.

Durability and Environmental Resistance

The durability and environmental resistance of neon strip lights are important factors, especially for outdoor applications or areas with harsh environmental conditions. If the strips are to be installed outdoors, they should be able to withstand exposure to sunlight, rain, snow, and temperature variations. Look for strips that are made of high - quality materials, such as weather - resistant silicone for LED - based strips or sturdy glass for traditional neon lights. Additionally, consider the resistance of the strips to moisture, dust, and other contaminants, as these can affect the performance and lifespan of the lights.

Market Trends and Future Developments in Neon Strip Lights

mart Lighting Integration

The future of neon strip lights is likely to be closely tied to smart lighting technology. With the increasing popularity of smart home and building automation systems, there is a growing demand for lighting products that can be controlled remotely and integrated with other smart devices. In the coming years, we can expect to see neon strip lights with built - in Wi - Fi, Bluetooth, or Zigbee connectivity, allowing users to control the lights using their smartphones, tablets, or voice - controlled assistants. Smart neon strip lights may also be able to sync with music, movies, or other media, creating dynamic and immersive lighting experiences.

Sustainable Manufacturing Practices

As environmental awareness continues to grow, there will be an increasing emphasis on sustainable manufacturing practices in the production of neon strip lights. Manufacturers will likely focus on using recycled materials, reducing energy consumption during production, and implementing waste - reduction and recycling programs. There may also be a shift towards more eco - friendly packaging for neon strip lights. Additionally, the development of more energy - efficient LEDs and the use of sustainable power sources, such as solar energy, may become more prevalent in the production of these lights.

Advancements in Lighting Effects and Color Options

The lighting industry is constantly evolving, and neon strip lights are no exception. In the future, we can expect to see advancements in lighting effects and an even wider range of color options. Manufacturers may develop new ways to create more realistic and vibrant color - changing effects, as well as new techniques for diffusing light to create unique visual experiences. There may also be an increased focus on creating neon strip lights with high - quality color - rendering capabilities, ensuring that colors appear true to life under the illumination of the strips.

Conclusion

Neon strip lights have come a long way from their humble beginnings as simple signage lights. Today, they are a versatile and popular lighting solution that offers a combination of style, functionality, and energy efficiency. Whether used in interior decor, commercial spaces, or architectural and landscape lighting, neon strip lights have the ability to transform any environment and create a captivating visual impact.

When choosing neon strip lights, it is important to consider factors such as light output, color, power requirements, durability, and environmental resistance. By making an informed decision, users can select the perfect neon strip lights for their specific needs and applications.

As the market for neon strip lights continues to grow, we can look forward to exciting advancements in technology, sustainable manufacturing practices, and lighting effects. These developments will not only enhance the performance and versatility of neon strip lights but also make them an even more attractive option for a wide range of lighting applications.

In conclusion, neon strip lights are not just a source of illumination; they are a statement of style and innovation in the world of lighting.