Time:2025-06-09

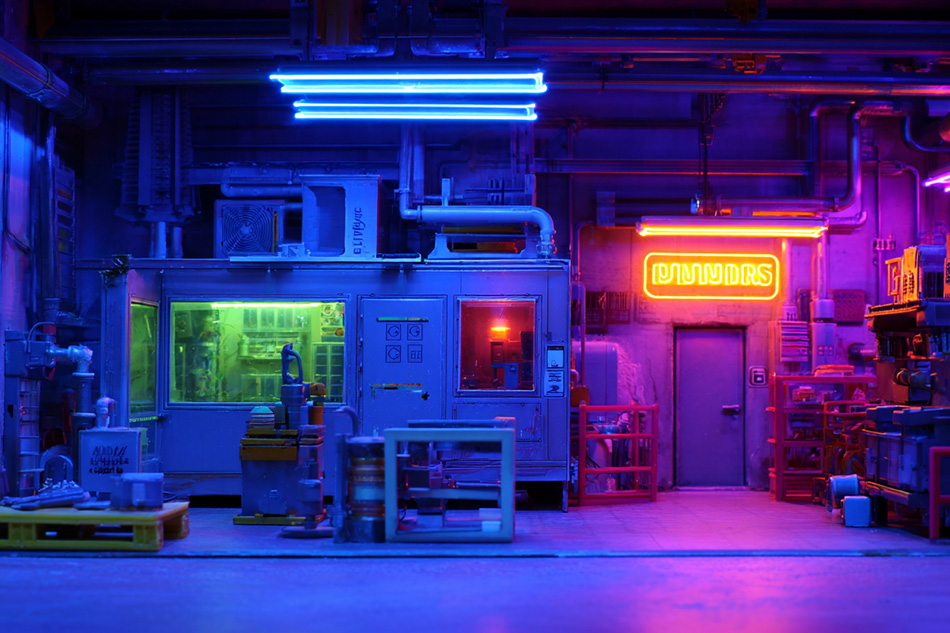

In the demanding realm of industrial machinery operations, proper lighting is not merely an aesthetic consideration but a critical safety and operational necessity. The advent of 6x12mm neon flex has brought about a significant transformation in the way industrial machinery is illuminated, offering a combination of functionality, durability, and energy efficiency that meets the unique requirements of industrial environments. This article explores the key attributes, applications, and benefits of 6x12mm neon flex for industrial machinery lighting, as well as considerations for its effective implementation.

The Unique Requirements of Industrial Machinery Lighting

Safety First

Industrial machinery operates in environments where visibility is crucial for preventing accidents. Workers need to clearly see moving parts, control panels, and workpieces to ensure safe operation. Adequate lighting reduces the risk of misoperation, collisions, and injuries. Additionally, proper lighting helps in quickly identifying any malfunctions or wear - and - tear on the machinery, enabling timely maintenance and reducing downtime.

Harsh Environment Resistance

Industrial settings are often characterized by harsh conditions, including high temperatures, dust, moisture, vibrations, and exposure to chemicals. Lighting solutions for industrial machinery must be able to withstand these elements without compromising performance or safety. They need to be durable enough to endure constant vibrations from the machinery and resistant to dust and moisture that can penetrate and damage internal components.

Precision and Visibility

Many industrial processes require a high level of precision. Clear and consistent lighting is essential for workers to accurately perform tasks such as assembly, inspection, and quality control. Lighting that provides uniform illumination without creating glare or shadows is crucial for maintaining the quality and efficiency of industrial operations.

Key Features of 6x12mm Neon Flex for Industrial Use

Compact and Flexible Design

The 6x12mm dimension of the neon flex makes it highly compact, allowing it to be easily installed in tight spaces within industrial machinery. Its flexibility enables it to be bent and shaped around complex machinery structures, such as pipes, gears, and frames. This adaptability ensures that the lighting can be precisely positioned to illuminate the areas that need it most, without interfering with the machinery's operation.

Exceptional Durability

Constructed with high - quality materials, 6x12mm neon flex is designed to withstand the rigors of industrial environments. The outer casing is often made of robust materials that are resistant to impacts, abrasions, and chemicals. It can endure continuous vibrations from the machinery without damage, ensuring a long lifespan even in the most demanding conditions. Moreover, the internal components, including the LED light sources, are engineered for reliability, reducing the frequency of replacements and maintenance.

High - Intensity and Uniform Illumination

To meet the precision and visibility requirements of industrial operations, 6x12mm neon flex provides high - intensity lighting. The LED technology used in these neon flex strips emits a bright and consistent light, ensuring that all areas of the machinery are well - illuminated. The light distribution is designed to be uniform, minimizing shadows and glare that could otherwise impede worker visibility and accuracy. This high - quality illumination is essential for tasks that demand detailed visual inspection and precise manipulation of components.

Energy - Efficiency

In an industrial setting where energy consumption can be substantial, the energy - efficient nature of 6x12mm neon flex is a significant advantage. Compared to traditional lighting options, these neon flex strips consume significantly less power while still delivering excellent lighting performance. Reduced energy consumption not only helps industrial facilities cut down on electricity costs but also contributes to a more sustainable and environmentally friendly operation.

Safety - Oriented Design

Safety is a top priority in industrial environments, and 6x12mm neon flex is designed with this in mind. It typically operates at low voltages, reducing the risk of electric shock. The materials used in its construction are non - toxic and do not emit harmful fumes, even under high - temperature conditions. Additionally, the low heat emission of the LED light sources minimizes the risk of fire hazards, making it a safe lighting solution for industrial machinery.

Applications of 6x12mm Neon Flex in Industrial Machinery

Machine Tool Lighting

In machining centers, lathes, milling machines, and other machine tools, 6x12mm neon flex can be installed to illuminate the work area. This allows operators to clearly see the cutting process, the condition of the workpiece, and any potential issues with the tooling. By providing focused and bright lighting, it helps improve machining accuracy and reduces the likelihood of errors.

Conveyor System Illumination

Conveyor systems are integral to many industrial processes. 6x12mm neon flex can be used to light up the conveyor belts, ensuring that workers can easily monitor the movement of materials, detect any jams or blockages, and identify damaged or defective products. The flexibility of the neon flex enables it to be installed along the length and around the curves of the conveyor system, providing consistent illumination throughout.

Control Panel and Instrument Lighting

Industrial machinery is equipped with numerous control panels and instruments. Proper lighting of these areas is essential for operators to read gauges, switch controls, and monitor system status accurately. 6x12mm neon flex can be strategically placed around control panels to provide clear and non - obtrusive lighting, enhancing operational efficiency and safety.

Inspection and Quality Control Stations

At inspection and quality control stations, where detailed visual examination of products is required, 6x12mm neon flex offers the high - quality illumination needed. It ensures that every detail of the product can be seen clearly, enabling inspectors to identify any defects or deviations from the quality standards promptly.

Installation and Maintenance Considerations

Professional Installation

While 6x12mm neon flex is relatively easy to install, it is recommended that installation in industrial machinery be carried out by professionals. They have the expertise to ensure proper wiring, secure mounting, and compliance with safety regulations. Professional installers can also optimize the positioning of the neon flex to achieve the best lighting 效果 for the specific machinery and operational requirements.

Routine Maintenance

Regular maintenance is crucial to ensure the continued performance of 6x12mm neon flex in industrial machinery. This includes periodic inspections to check for any signs of damage, such as cracks in the casing or loose connections. Cleaning the neon flex to remove dust and debris that can accumulate in industrial environments is also important. In addition, monitoring the light output and replacing any faulty LED components in a timely manner will help maintain the effectiveness of the lighting system.

Choosing the Right Supplier

Industry Experience and Reputation

When selecting a supplier for 6x12mm neon flex for industrial machinery lighting, look for companies with extensive experience in the industrial lighting sector. A supplier with a good reputation is more likely to offer high - quality products that meet the demanding requirements of industrial environments. Check for customer reviews, testimonials, and case studies to gauge the supplier's track record.

Product Certifications

Ensure that the neon flex products offered by the supplier have the necessary certifications. Certifications such as CE, RoHS, and UL indicate that the products comply with safety, environmental, and quality standards. These certifications are essential for ensuring the reliability and safety of the lighting solution in an industrial setting.

Technical Support and After - Sales Service

Industrial machinery lighting installations may require technical support during and after installation. A good supplier should offer comprehensive technical support, including assistance with product selection, installation guidance, and troubleshooting. Reliable after - sales service, such as a warranty and prompt replacement of defective products, is also important for minimizing downtime and ensuring the long - term performance of the lighting system.

Customization Options

Industrial machinery comes in various shapes and sizes, with unique lighting requirements. A supplier that offers customization options for 6x12mm neon flex, such as custom lengths, colors, and mounting solutions, can better meet the specific needs of different industrial applications.

Conclusion

6x12mm neon flex has emerged as an innovative and effective lighting solution for industrial machinery, addressing the unique challenges and requirements of industrial environments. Its compact and flexible design, durability, high - intensity illumination, energy - efficiency, and safety features make it an ideal choice for enhancing safety, precision, and operational efficiency in industrial settings. By understanding its applications, following proper installation and maintenance practices, and choosing the right supplier, industrial facilities can fully leverage the benefits of 6x12mm neon flex to optimize their machinery lighting and drive overall productivity. As industrial technology continues to evolve, 6x12mm neon flex is likely to play an even more significant role in shaping the future of industrial machinery lighting.