Time:2025-06-21

In the dynamic realm of lighting solutions, custom silicone neon light strips have gained significant traction, offering unparalleled flexibility and aesthetic appeal for diverse projects. Whether it's for unique interior design concepts, distinctive commercial signage, or specialized architectural lighting, the demand for customized neon light strips continues to rise. When embarking on a custom silicone neon light strip project, understanding factory quotes is crucial. This article delves deep into the intricacies of custom silicone neon light strip factory quotes, exploring the factors influencing them, the quoting process, and how to make the most informed decisions.

The Growing Demand for Custom Silicone Neon Light Strips

Diverse Project Requirements

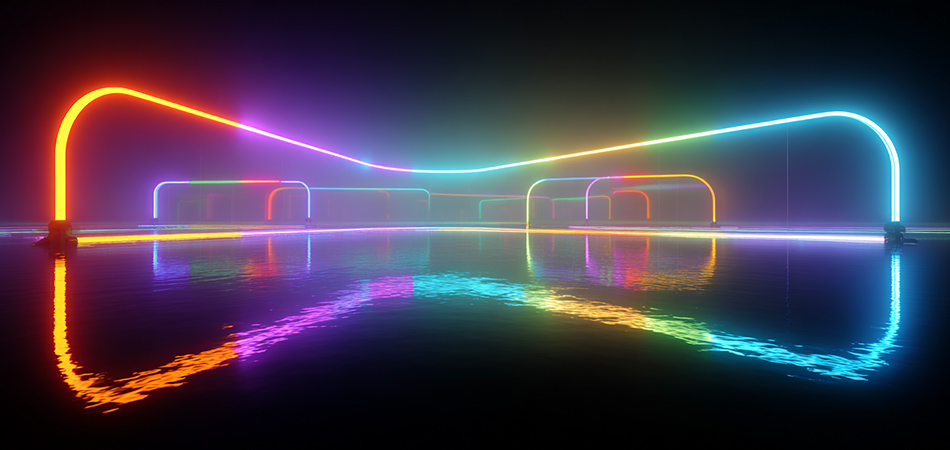

The versatility of custom silicone neon light strips makes them a preferred choice across various industries. In the interior design sector, designers often seek to create one - of - a - kind lighting schemes that reflect the unique style and personality of a space. Custom neon light strips can be shaped, colored, and sized to fit specific design elements, such as highlighting the contours of a custom - built furniture piece or adding a creative touch to a feature wall.

For commercial enterprises, custom neon light strips offer a powerful branding tool. Retail stores can use them to create eye - catching window displays that incorporate their brand colors and logo, while restaurants and cafes can design unique lighting setups that enhance the dining atmosphere and set them apart from competitors. In the architectural field, custom neon light strips are employed to accentuate the distinctive features of buildings, whether it's a historical structure or a modern skyscraper, adding a touch of elegance and innovation to the overall design.

The Need for Personalization

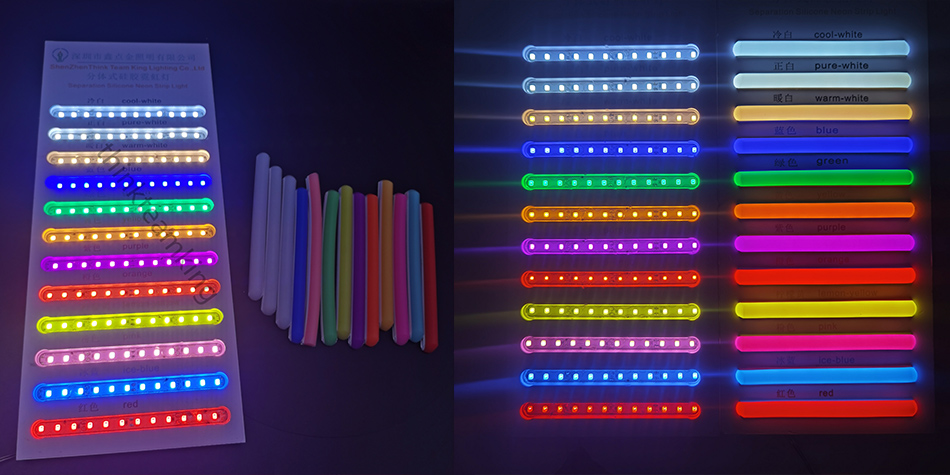

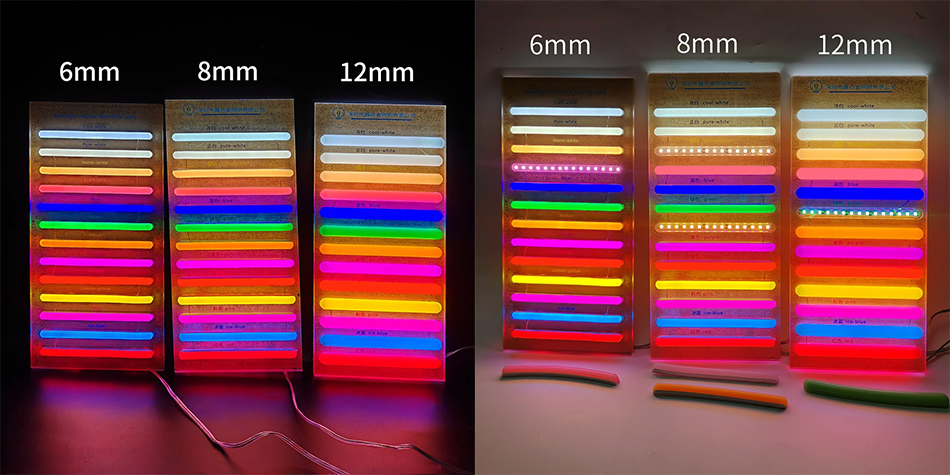

Today's consumers and businesses place a high value on personalization. Custom silicone neon light strips allow for the creation of lighting solutions that are tailored precisely to individual needs and preferences. From choosing a specific color temperature to match the ambiance of a room to designing a unique shape that complements the architecture of a building, the ability to customize every aspect of the neon light strip ensures that the final product is not only functional but also a work of art that stands out.

Key Factors Influencing Custom Silicone Neon Light Strip Factory Quotes

Design Complexity

The complexity of the custom design is a major determinant of the factory quote. A simple, straight - shaped neon light strip with a single color will generally cost less compared to a design that involves intricate curves, multiple bends, or a combination of different colors and lighting effects. The more complex the design, the more time and expertise are required during the manufacturing process, which in turn increases the production cost and, consequently, the quote.

For example, a custom neon light strip designed to spell out a company name in a stylized font with color - changing capabilities will involve additional steps such as precise cutting of the strip to fit the letter shapes, programming the color - changing sequences, and ensuring the electrical connections are accurate. All these factors contribute to a higher quote due to the increased labor and technical requirements.

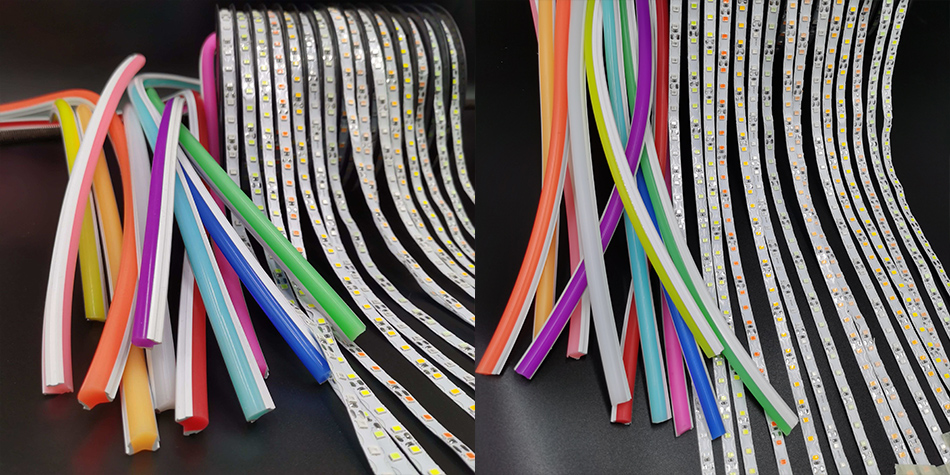

Material Quality

The quality of the materials used in the production of custom silicone neon light strips has a significant impact on the quote. High - quality silicone offers better protection for the internal LED components, ensuring durability, resistance to environmental factors like moisture and UV rays, and a more uniform light diffusion. Similarly, premium - grade LED chips provide better brightness, color accuracy, and a longer lifespan.

Factories that source top - notch materials will typically charge more for their products. However, investing in high - quality materials can result in a more reliable and long - lasting neon light strip, reducing the need for frequent replacements and maintenance in the long run. On the other hand, using lower - quality materials may lead to a lower initial quote but could potentially result in higher costs down the line due to performance issues and premature failure.

Quantity Ordered

Economies of scale play a role in custom silicone neon light strip factory quotes. Generally, the larger the quantity of custom neon light strips ordered, the lower the per - unit cost. Factories are able to spread out fixed costs, such as setup costs for production runs and design development, over a larger number of units when producing in bulk. This allows them to offer more competitive pricing for larger orders.

For instance, a small business ordering a limited number of custom neon light strips for a one - time promotional event may receive a higher per - unit quote compared to a large - scale retailer placing a substantial order for multiple store locations. Understanding the relationship between quantity and cost can help customers optimize their budget when planning their custom neon light strip projects.

Additional Features and Customizations

Any additional features or customizations requested beyond the standard product offering will also affect the factory quote. This could include integrating specialized control systems, such as wireless controllers for remote operation, sensors for motion - activated lighting, or dimming capabilities. Adding protective coatings for enhanced durability in harsh environments or incorporating unique packaging designs for branding purposes are other examples of customizations that can increase the cost.

Each additional feature requires additional components, engineering, and testing, all of which contribute to the overall production cost and, ultimately, the final quote provided by the factory.

The Custom Silicone Neon Light Strip Factory Quoting Process

Initial Inquiry and Design Submission

The quoting process begins with the customer submitting an initial inquiry to the factory. This typically includes providing details about the project, such as the intended application of the custom neon light strip, a description of the desired design (if possible, accompanied by sketches or digital renderings), and any specific requirements or preferences regarding color, size, and functionality.

Based on this information, the factory's sales or design team will review the inquiry and may request further clarification or additional details to ensure they have a comprehensive understanding of the customer's needs. This initial communication is crucial for the factory to accurately assess the scope of the project and provide an appropriate quote.

Design Evaluation and Cost Estimation

Once the factory has all the necessary information, the design is evaluated by their internal team. They consider factors such as the complexity of the design, the materials required, and the production processes needed to bring the design to life. The engineering and production departments work together to estimate the labor costs, material costs, and any additional expenses associated with the project.

During this stage, the factory may also take into account their current production capacity and any potential challenges or constraints that could impact the production timeline or cost. Based on this detailed evaluation, they calculate a preliminary cost estimate for the custom silicone neon light strip project.

Quote Preparation and Submission

After the cost estimation is complete, the factory prepares a formal quote for the customer. The quote typically includes a breakdown of the costs, detailing the price of materials, labor, any additional features or customizations, and any applicable taxes or shipping fees. It also specifies the estimated production timeline, including the lead time for design development, manufacturing, and delivery.

The quote is then submitted to the customer, usually via email or through an online portal. Along with the quote, the factory may provide additional information or suggestions to help the customer make an informed decision, such as alternative design options that could reduce costs without sacrificing too much on the desired functionality or aesthetic.

Quote Negotiation and Finalization

Once the customer receives the quote, they have the opportunity to review it and negotiate with the factory if necessary. This could involve discussing ways to reduce costs, such as simplifying the design, using alternative materials, or adjusting the quantity ordered. The factory, on its part, may be willing to offer some flexibility in the pricing or terms based on the customer's requirements and the nature of the project.

Through this negotiation process, both parties work towards reaching an agreement that satisfies the customer's needs and budget while also being viable for the factory. Once the terms are agreed upon, the quote is finalized, and a contract or purchase order may be signed to formalize the agreement and initiate the production process.

How to Obtain Accurate Custom Silicone Neon Light Strip Factory Quotes

Provide Detailed Project Information

To receive an accurate quote, it's essential for the customer to provide as much detailed information as possible about the project at the initial inquiry stage. This includes clear specifications regarding the design, such as the exact dimensions, shape, and color requirements. If there are specific functional requirements, like the need for a certain level of brightness, color - changing capabilities, or waterproofing, these should also be clearly communicated.

Providing reference images, sketches, or digital models of the desired custom neon light strip can greatly assist the factory in understanding the customer's vision and enabling them to provide a more precise quote. The more information the factory has, the better they can assess the complexity of the project and accurately estimate the costs involved.

Research and Compare Multiple Factories

It's advisable for customers to research and obtain quotes from multiple custom silicone neon light strip factories. Different factories may have varying cost structures, production capabilities, and levels of expertise. By comparing quotes from several sources, customers can get a better sense of the market price range for their specific project requirements.

In addition to price, it's important to consider other factors such as the factory's reputation for quality, their experience in handling similar projects, and their customer service. Reading customer reviews, checking for certifications, and asking for samples or references can help in evaluating the suitability of each factory. This research and comparison process can ultimately lead to finding a factory that offers the best combination of quality, service, and price for the custom neon light strip project.

Communicate Clearly and Regularly

Maintaining clear and regular communication with the factory throughout the quoting process is crucial. If there are any changes or updates to the project requirements, they should be promptly communicated to the factory to ensure that the quote remains accurate. Similarly, if the customer has any questions or concerns about the quote, they should not hesitate to reach out to the factory for clarification.

Open and transparent communication helps to build a good relationship between the customer and the factory, reduces the likelihood of misunderstandings, and increases the chances of a successful outcome. It also allows the factory to better understand the customer's needs and make any necessary adjustments to the quote or production plan.

Understanding the Fine Print in Custom Silicone Neon Light Strip Factory Quotes

Terms and Conditions

The terms and conditions included in the factory quote are an important aspect that customers should carefully review. These terms cover various aspects such as payment terms, delivery terms, and warranty policies. Payment terms may specify the due date for payment, the acceptable payment methods, and any penalties for late payment.

Delivery terms outline the estimated delivery time, the shipping method, and who is responsible for any shipping costs or customs duties. Warranty policies detail the length of the warranty, what is covered under the warranty, and the process for filing a claim in case of a product defect. Understanding these terms and conditions is essential to avoid any unexpected issues or costs during the project.

Hidden Costs

In some cases, there may be hidden costs that are not immediately apparent in the factory quote. These could include additional fees for design revisions beyond a certain limit, charges for expedited production or delivery, or costs associated with special packaging or labeling requirements.

Customers should carefully review the quote to identify any potential hidden costs and clarify them with the factory before finalizing the agreement. This can help prevent unpleasant surprises and ensure that the total cost of the project aligns with the customer's budget.

Intellectual Property Rights

For custom silicone neon light strip projects, intellectual property rights can be a significant consideration. It's important to clarify who owns the design and any associated intellectual property rights. Some factories may retain certain rights to the design, while others may transfer the full intellectual property rights to the customer upon completion of the project and payment.

Understanding the intellectual property rights associated with the custom neon light strip can protect the customer's interests, especially if they plan to use the design for branding or marketing purposes in the future.

Tips for Making the Most of Custom Silicone Neon Light Strip Factory Quotes

Plan Ahead

Planning the custom neon light strip project well in advance can provide several advantages when it comes to obtaining factory quotes. By giving the factory sufficient time to review the project requirements, develop the design, and prepare the quote, customers can avoid rush fees or expedited production costs.

Early planning also allows for more time to research and compare different factories, negotiate better terms, and make any necessary adjustments to the project plan to optimize the budget. Additionally, it provides a buffer in case there are any delays or unforeseen issues during the quoting or production process.

Collaborate with the Factory

Establishing a collaborative relationship with the custom silicone neon light strip factory can lead to a more successful project outcome. By working closely with the factory's design and engineering teams, customers can benefit from their expertise and suggestions. The factory may be able to offer alternative design ideas or material options that can achieve the desired look and functionality at a lower cost.

Collaboration also ensures that both parties have a clear understanding of the project goals and expectations, reducing the likelihood of misunderstandings and rework during the production process. Regular communication and feedback loops can help keep the project on track and result in a custom neon light strip that meets or exceeds the customer's expectations.

Consider Long - Term Costs

When evaluating factory quotes, it's important to consider not only the initial purchase price but also the long - term costs associated with the custom silicone neon light strip. A lower - priced quote may seem attractive initially, but if it means using lower - quality materials or sacrificing certain features, it could lead to higher maintenance costs, shorter lifespan, and potential replacement costs in the future.

On the other hand, investing in a higher - quality custom neon light strip with a slightly higher upfront cost may prove to be more cost - effective in the long run due to its durability and reliability. Customers should weigh the initial cost against the long - term benefits to make an informed decision that aligns with their overall project budget and goals.

Future Trends in Custom Silicone Neon Light Strip Factory Quotes

Integration of Smart Technologies

As the demand for smart lighting solutions continues to grow, custom silicone neon light strip factories are likely to incorporate more smart technologies into their products. This could include features such as Internet of Things (IoT) connectivity, allowing for remote control and monitoring of the neon light strips through mobile apps or smart home systems.

The integration of smart technologies may impact factory quotes, as it requires additional components, software development, and testing. However, it also presents opportunities for factories to offer more value - added services and differentiate themselves in the market. Customers can expect to see more advanced and customized smart lighting options in the future, with corresponding adjustments in the quoting process to reflect the increased complexity and functionality.

Focus on Sustainability

With the increasing global emphasis on sustainability, custom silicone neon light strip factories are likely to place a greater focus on using eco - friendly materials and production processes. This could involve using recycled or biodegradable silicone, energy - efficient LED chips, and reducing waste during the manufacturing process.

While the use of sustainable materials and practices may initially result in higher production costs and potentially higher quotes, it also appeals to environmentally conscious customers. In the long run, as the demand for sustainable products grows and economies of scale are achieved, the cost of sustainable custom neon light strips is expected to become more competitive. Factories that embrace sustainability early on may gain a competitive edge in the market, and customers can anticipate more options for eco - friendly custom lighting solutions in the future.

Advanced Design and Customization Tools

Advancements in digital design and manufacturing technologies are likely to revolutionize the way custom silicone neon light strip projects are designed and quoted. Factories may adopt more advanced 3D design tools, virtual reality (VR), and augmented reality (AR) technologies to enable customers to visualize their custom neon light strip designs more accurately before production.

These advanced design tools can also streamline the quoting process by allowing for more precise cost estimations based on the digital models. Additionally, they may enable more complex and intricate customizations, expanding the creative possibilities for customers. As these technologies become more prevalent, customers can expect a more seamless and interactive experience when working with factories to obtain custom silicone neon light strip quotes.

In conclusion, understanding custom silicone neon light strip factory quotes is essential for anyone looking to embark on a custom lighting project. By being aware of the factors influencing quotes, the quoting process, and how to make informed decisions, customers can ensure that they receive accurate quotes, select the right factory, and achieve the desired custom neon light strip solution that meets their needs, budget, and aesthetic preferences. As the industry continues to evolve, staying updated on the latest trends and developments in custom neon light strip manufacturing and quoting will be key to successfully navigating the world of tailored lighting solutions.