Outdoor lighting projects demand more than a “nice glow.” For commercial signage, architectural outlines, and exterior brand displays, performance depends on water resistance, UV stability, reliable sealing, and long-term electrical safety. That’s why more contractors, sign factories, and OEM buyers are upgrading to waterproof neon lights—a modern LED neon solution engineered to deliver the classic neon look with better durability and lower maintenance.

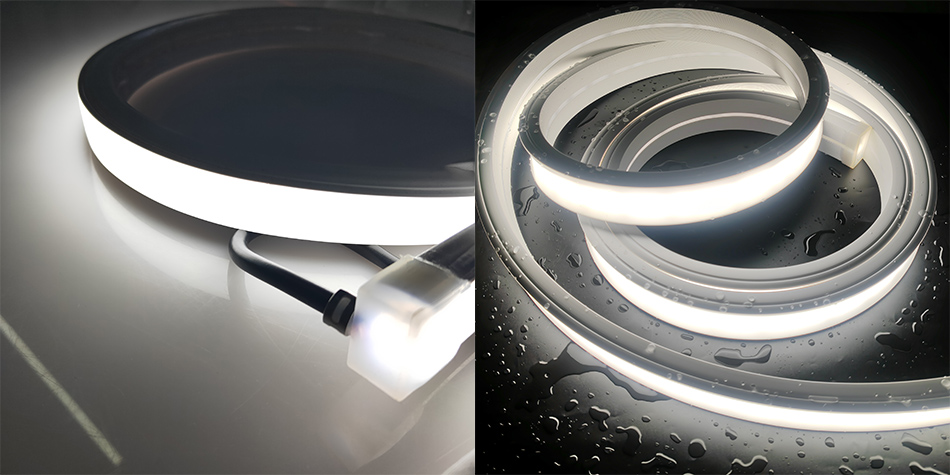

Unlike traditional glass neon, LED neon flex uses LEDs inside a diffused silicone (or similar) housing to create a smooth, continuous line of light. When designed correctly, waterproof neon lights can withstand rain, humidity, and temperature changes while maintaining consistent brightness for years in outdoor environments.

This guide explains how to choose the right waterproof neon solution for commercial use, including IP68 waterproof neon strip lights, 12V waterproof silicone neon strips, cuttable waterproof neon light strips, and waterproof neon lights with remote control.

What Are Waterproof Neon Lights?

Waterproof neon lights are flexible LED neon products designed with sealed housings and protective components to resist water ingress. They are commonly used for:

Outdoor signage and storefront branding

Architectural façade outlines and building edges

Canopies, entrances, and perimeter lighting

Hospitality exteriors (restaurants, hotels, bars)

Outdoor display zones and themed environments

Most waterproof neon lights are built with a silicone diffuser that produces a dot-free neon line. For outdoor applications, “waterproof” is not only about the strip body—it also depends on end caps, joints, connectors, and cable exits. A high-quality system treats waterproofing as a complete design, not an afterthought.

Why Waterproof Neon Lights Are Ideal for Outdoor Commercial Projects

1) Strong Visual Impact with a Clean Neon Line

Outdoor signage is often viewed from a distance. Waterproof neon lights provide a smooth, continuous outline that stays readable and premium-looking—especially compared with standard LED strips that can show visible LED points.

2) Durability for Jobsite Handling and Long Runtime

Commercial outdoor projects often operate 10–16 hours per day. Durable materials and stable LED selection reduce maintenance frequency and improve lifecycle value—critical for contractors and multi-location brands.

3) Lower Risk and Easier Installation Than Glass Neon

Traditional neon glass is fragile and requires specialized handling. Waterproof LED neon flex is easier to transport and install, making it more suitable for scalable commercial deployment.

Understanding Waterproof Ratings: What IP68 Means in Real Projects

Many buyers search specifically for IP68 waterproof neon strip lights, but it’s important to understand what makes an installation truly waterproof.

IP68 waterproof neon strip lights are typically specified for locations with strong water exposure, where the product design may tolerate frequent splashing, heavy rain, or extended wet conditions (depending on the manufacturer’s construction and test standard).

Real-world performance still depends on installation methods, especially around cut ends, joints, and power connections.

Practical takeaway: If you require IP68, confirm the full system approach—sealed connectors, approved end caps, and the correct sealing process after cutting. Waterproofing is only as strong as the weakest entry point.

Key Product Options for B2B Buyers

12V Waterproof Silicone Neon Strips

For commercial projects, 12V waterproof silicone neon strips are popular because low-voltage operation improves installation safety and works well with commonly used power supplies and controllers. These strips are widely used for:

Storefront outlines and outdoor brand signage

Architectural accents under canopies

Exterior decorative lines in hospitality venues

Outdoor wayfinding and perimeter highlights

Why 12V matters: Low voltage helps reduce risk during installation and can simplify maintenance—especially when multiple zones are distributed across a façade or signage system.

Cuttable Waterproof Neon Light Strips

Most outdoor projects require precise lengths. Cuttable waterproof neon light strips help installers fit corners, outlines, and custom shapes while reducing material waste.

Common commercial uses include:

Channel-letter outlines and logo shapes

Building perimeter runs with multiple turns

Modular façade segments for phased installation

Critical note: Cutting creates a potential water entry point. For cuttable waterproof neon light strips, the sealing process (end caps, silicone sealing, heat-shrink, or manufacturer-approved kits) must be followed exactly to maintain waterproof performance—especially for outdoor exposure.

IP68 Waterproof Neon Strip Lights

When projects face heavy rain, wash-down zones, or high humidity, IP68 waterproof neon strip lights are often specified for added protection. They’re typically selected for:

Outdoor architectural lines with frequent rain exposure

Waterfront or high-humidity installations

Locations where water pooling or splashing is likely

For B2B sourcing, always confirm:

bending direction (top-bend vs side-bend)

UV resistance and anti-yellowing performance

connector sealing method

cut-and-reseal instructions for maintaining IP performance

Waterproof Neon Lights with Remote Control

For many commercial projects, lighting needs to be adjustable—whether to match branding colors, reduce brightness late at night, or switch scenes for promotions. Waterproof neon lights with remote control are a practical solution for:

Restaurants and bars changing mood lighting

Retail storefronts running seasonal campaigns

Outdoor feature walls and photo zones

Hospitality entrances requiring scheduled dimming

To improve outdoor reliability, remote-control systems should include:

protected controller placement (enclosure recommended)

sealed junctions and stable wiring connections

correct power planning for all zones

Remote control may be implemented via RF remotes, smart controllers, or integrated building systems depending on project complexity.

Waterproof Neon Lights vs. Standard LED Strip Lights Outdoors

Many buyers compare waterproof neon to standard waterproof LED strips. Here’s the commercial perspective:

Appearance

Waterproof neon lights: smooth, continuous neon line; premium direct-view effect

Standard LED strips: may show LED dots; needs diffusers/channels for similar look

Installation

Waterproof neon lights: mounted with clips/channels for clean outline runs

Standard LED strips: better for hidden coves and indirect lighting

Best Use Cases

Waterproof neon lights: signage, outlines, visible decorative runs

Standard LED strips: indirect lighting, backlighting, utility illumination

If the lighting is directly visible to customers, waterproof neon lights usually deliver better visual ROI.

What to Specify When Buying Waterproof Neon Lights in Bulk

If you’re sourcing as a contractor, sign factory, or distributor, define these specs upfront:

Waterproof level (confirm whether IP68 waterproof neon strip lights are truly required)

Voltage (12V waterproof silicone neon strips are common for commercial safety)

Cut interval (for cuttable waterproof neon light strips—cut points and reseal method)

Bending direction (top-bend/side-bend to match design geometry)

Mounting method (clips, aluminum channels; avoid unreliable outdoor adhesion alone)

Control requirement (waterproof neon lights with remote control; controller location plan)

Operating hours & brightness target (standard vs high output)

Batch consistency (critical for multi-site rollouts and repeated projects)

Clear specifications reduce rework, improve lead times, and minimize field failures.

Conclusion: Outdoor Neon That’s Built to Last

Outdoor commercial lighting must withstand weather while maintaining brand-level presentation. Waterproof neon lights deliver a clean neon line, durable construction, and energy-efficient operation—making them ideal for signage, architectural outlines, and exterior commercial projects.

Whether your project requires IP68 waterproof neon strip lights for demanding environments, 12V waterproof silicone neon strips for safer low-voltage installation, cuttable waterproof neon light strips for precise fitting, or waterproof neon lights with remote control for flexible scene control, the key is choosing the right specifications—and working with a manufacturing partner who understands commercial-grade waterproofing as a complete system.

FAQ: Waterproof Neon Lights

1) What are waterproof neon lights, and where are they commonly used?

Waterproof neon lights are sealed LED neon flex products designed to resist water ingress in outdoor or humid environments. They are commonly used for outdoor signage, storefront outlines, architectural façade lighting, and exterior décor where long runtime and reliable waterproof protection are required.

2) Are IP68 waterproof neon strip lights necessary for every outdoor project?

Not always. IP68 waterproof neon strip lights are best for environments with heavy water exposure, wash-down conditions, or high-humidity installations. For protected areas under canopies or light rain exposure, lower waterproof levels may be sufficient—always match the IP requirement to real installation conditions.

3) Why do many installers prefer 12V waterproof silicone neon strips?

12V waterproof silicone neon strips are popular because low-voltage systems improve installation safety and integrate easily with common power supplies. They also support stable operation for long daily runtime in commercial outdoor projects.

4) Can cuttable waterproof neon light strips remain waterproof after cutting?

Yes—cuttable waterproof neon light strips can remain waterproof if they are cut at the correct marked intervals and resealed properly using approved end caps and sealing methods. Proper sealing is critical for maintaining waterproof performance, especially in outdoor environments.

5) How do waterproof neon lights with remote control work in outdoor installations?

Waterproof neon lights with remote control use a controller (RF, smart, or system-integrated) to adjust brightness, colors, and effects. For outdoor reliability, the controller should be protected in a suitable enclosure, and all wiring connections should be sealed to prevent moisture ingress.

Related Articles

Best Waterproof Neon Lights: Enhance Your Outdoors

Versatile Cuttable Waterproof Neon Light Strips

Waterproof Neon Lights: Stylish Remote-Control Lighting

Best Waterproof Neon Lights: Outdoor Lighting Guide

Cuttable Waterproof Neon Light Strips: Versatile Glow for Indoor & Outdoor Environments

Waterproof Neon Lights: Versatile Illumination for Wet and Outdoor Environments