Time:2025-11-14

Neon sign makers stand as the bridge between creative vision and luminous reality, catering to businesses, designers, and homeowners seeking to elevate spaces with custom signage. Whether you prioritize local collaboration or global expertise, the right neon sign maker combines craftsmanship, technology, and personalized service to deliver signs that align with your brand identity, architectural needs, and aesthetic preferences. From LED neon strip-based creations to handcrafted glass designs, these makers leverage materials like flexible LED silicone strips, energy-efficient LED modules, and eco-friendly casings to produce durable, eye-catching signs that span commercial storefronts, residential decor, architectural accents, and event installations.

The landscape of neon sign makers encompasses global manufacturers with decades of expertise and local craftsmen offering hyper-tailored solutions. Here’s a breakdown of standout players across sectors:

Jasionlight (China): With 17+ years of experience exporting to the USA, EU, and beyond, this manufacturer specializes in LED neon signs using high-grade 2835 SMD and 5050 SMD LED chips for uniform brightness. Their one-stop production process includes PCB design, SMT precision assembly, and silicone extrusion, supported by an 8-member R&D team and strict QC inspections. Ideal for wholesale partners, project planners, and businesses seeking durable, eco-friendly signs at competitive prices.

Lumina Glow Designs (North America): A pioneer since 1998, this maker blends traditional craftsmanship with LED innovation, offering temperature-controlled units that outlast industry standards by 2-3 years. Their energy-efficient solutions are favored by hospitality businesses—one retro diner client reported a 40% boost in evening traffic after installing their custom “Eat Happy” sign. Specializes in architectural integration and Instagram-worthy commercial signage.

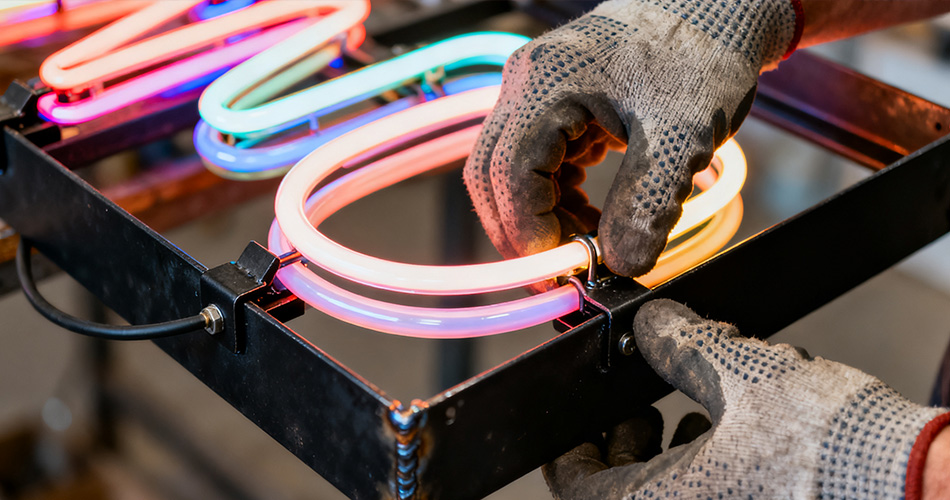

Neonova Sign Systems (Shanghai): Renowned for hand-bent glass tube artistry, Neonova maintains 17 quality checkpoints in their “glass-to-art” process, including custom gas formulation for richer color saturation. Their designs seamlessly embed into interior wall systems, making them a top choice for luxury retail and high-end hospitality projects worldwide.

Electro Lume Creations (Portland, USA): A modular innovation leader, their weatherproof neon signs feature military-grade sealants and tension-clip mounting systems that withstand coastal humidity and hurricane-force winds. Cafés and small businesses love their swapable message frames—perfect for seasonal promotions like “Hot Coffee Saves” (winter) and “Iced Magic Inside” (summer).

Local Craftsmakers: As highlighted in regional searches, local neon sign makers excel at on-site consultations, zoning compliance, and quick turnaround for urgent projects (e.g., pop-up shops, events). They adapt designs to local architectural styles—from historic building facades to urban storefronts—and provide hands-on installation and maintenance.

Selecting a neon sign maker requires balancing quality, expertise, and alignment with your specific needs. Use this checklist to identify professionals:

Verify focus on LED vs. traditional glass neon: LED neon sign makers (like Jasionlight and Lumina Glow) offer greater durability, energy efficiency, and flexibility for curved or custom shapes.

Match their specialty to your project: Hospitality brands may prioritize Lumina Glow’s color accuracy, while coastal businesses benefit from Electro Lume’s weather resistance.

Review past work for design diversity, craftsmanship (clean bends, uniform glow), and industry relevance.

Check third-party reviews (Google, social media) and client testimonials—consistent positive feedback indicates reliability.

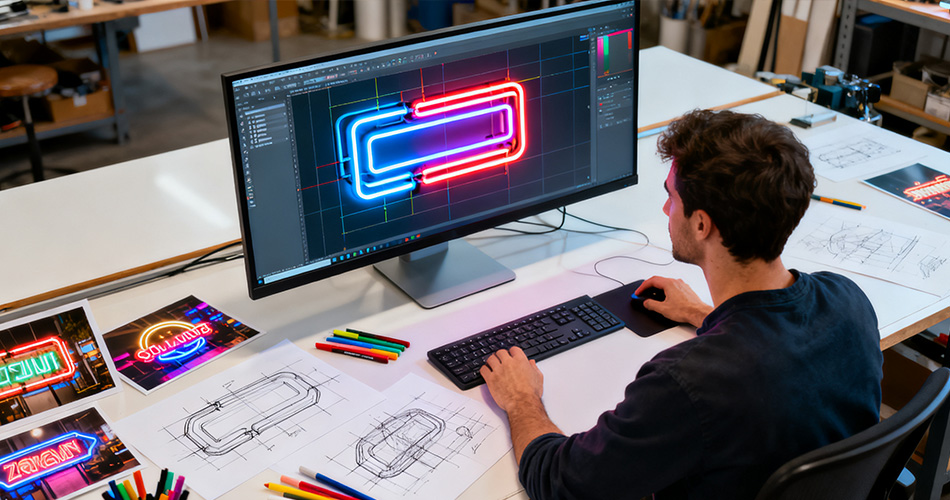

Ensure in-house design teams offer 3D mock-ups, custom sketches, and consultation to refine your vision.

Confirm adaptability to curved surfaces, architectural integration, and brand-specific requirements (e.g., logo replication, color matching).

Demand eco-friendly, durable materials: LED neon signs should use certified transformers, non-toxic silicone encasements, and high-lumen LED chips.

Inquire about construction details: No-splice designs (for uniform glow) and weather-resistant casings (for outdoor use) are key indicators of quality.

Prioritize makers offering design, fabrication, installation, and maintenance—this ensures accountability and seamless execution.

For commercial projects, confirm compliance with local safety regulations (e.g., electrical standards, zoning laws).

Compare quotes, but avoid sacrificing quality for cost: Durable LED neon signs reduce long-term maintenance expenses.

Clarify hidden fees (installation, shipping, revisions) and warranty coverage—reputable makers stand behind their products with service guarantees.

For smart spaces, choose makers whose signs integrate with LED electronic signs, smart lighting systems, or programmable modules.

Ask about dynamic features: Color-changing capabilities, animation sequencing (ideal for entertainment venues), or sync with audio/visual systems.

Neon sign makers cater to diverse use cases, leveraging their expertise to create tailored solutions:

Commercial Branding: Storefront signs (e.g., bakeries’ cursive logos, gyms’ bold geometric designs), indoor accents (restaurant vaulted ceiling traces, retail window displays).

Residential Decor: Personalized name signs, minimalist quote art, kids’ room playful shapes—all low-heat and wall-friendly.

Architectural Lighting: Facade highlights, staircase accents, and historic building preservation (non-damaging installations).

Events: Wedding backdrops, festival stage designs, corporate event branding—modular options for temporary or reusable setups.

Neon sign makers often guide clients toward LED neon for most projects, thanks to its distinct advantages over traditional glass neon. In terms of durability, LED neon is shatterproof and weather-resistant, making it suitable for both indoor and outdoor use, while traditional glass neon is fragile and prone to breakage if bumped or exposed to harsh conditions. Energy efficiency is another key difference: LED neon is significantly more efficient, consuming up to 80% less power than traditional glass neon, which translates to lower utility costs and a smaller environmental footprint. When it comes to customization, LED neon’s flexibility allows it to be shaped into intricate curves, custom forms, or complex logos with ease, whereas traditional glass neon is limited by the physical constraints of glass-bending techniques. Safety is also a priority for most clients—LED neon is mercury-free and emits minimal heat, making it safe for use around children, pets, and delicate materials, while traditional glass neon contains mercury and generates high levels of heat that can pose risks. Finally, maintenance requirements set the two apart: LED neon has an extensive lifespan of 50,000+ hours with minimal upkeep needed, while traditional glass neon requires frequent bulb replacements and ongoing maintenance to preserve its glow.

For retro aesthetics or high-end art installations where authentic vintage charm is a top priority, traditional glass neon (offered by specialized makers like Neonova) remains a premium choice. It’s particularly favored by luxury brands, historic venues, or clients seeking the classic, warm luminescence that only hand-bent glass tubes can deliver.