Time:2025-08-20

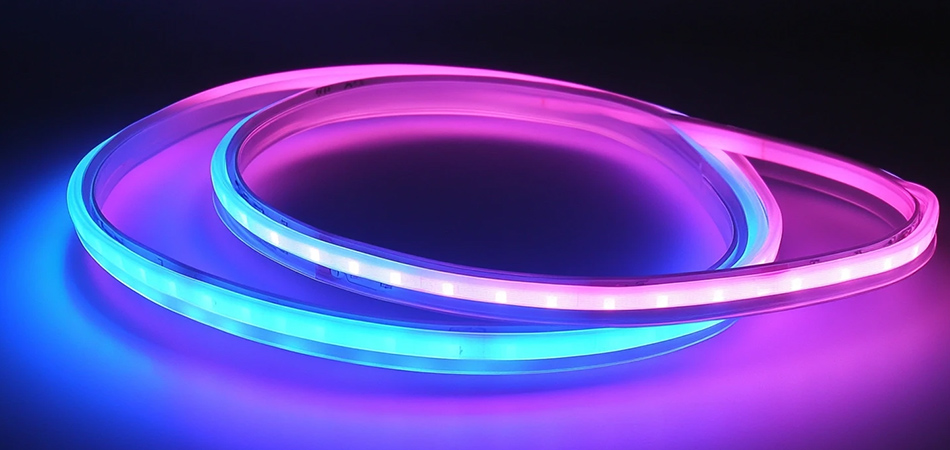

IP68 waterproof neon strip lights represent the pinnacle of water-resistant lighting, engineered to thrive in the harshest wet environments—from heavy rain and standing water to full submersion. Unlike lower-rated waterproof lights that withstand splashes or brief moisture exposure, IP68-rated strips are sealed to block dust and resist prolonged immersion, making them indispensable for applications where water is a constant presence. These strips combine the flexibility and illumination of standard neon lighting with a robust protective design, ensuring reliable performance in pools, marine settings, industrial washdown areas, and outdoor spaces exposed to extreme weather. Whether illuminating a swimming pool’s edge, highlighting a fountain, or powering signage in a rain-prone region, IP68 waterproof neon strip lights deliver consistent, vibrant light without compromise. This article explores their waterproofing technology, construction features, application versatility, installation considerations, and performance advantages, showcasing why they are the gold standard for moisture-resistant lighting.

The IP68 designation is a benchmark of protection, indicating that these neon strip lights meet rigorous standards for dust and water resistance. Ingress Protection (IP) coding classifies the level of protection, with the first digit (6) signifying complete dust tightness—no particles can penetrate the casing, ensuring internal components remain free from debris that could cause short circuits or wear. The second digit (8) denotes the highest water resistance rating, meaning the strip can withstand continuous submersion in water beyond 1 meter (specific depths vary by manufacturer but often exceed several meters) for extended periods without damage. This exceeds the capabilities of IP67-rated lights, which are limited to temporary submersion, making IP68 strips the choice for permanent underwater or high-moisture applications.

Testing standards for IP68 certification involve rigorous protocols to validate performance. Manufacturers subject the strips to prolonged submersion in static or flowing water, simulating real-world conditions like pool environments or flooded areas. They also test resistance to water pressure, ensuring the seal remains intact even when submerged at depth. These tests verify that the lights maintain full functionality—no dimming, flickering, or color distortion—both during and after submersion, confirming their reliability in critical applications where failure could lead to safety hazards or costly repairs.

Practical implications of the IP68 rating extend beyond mere water resistance. The dust tightness ensures the strips perform in dirty or industrial environments, such as factories with airborne particles or construction sites, where debris could otherwise damage internal components. The water resistance guarantees operation in continuous moisture, including high-humidity spaces like greenhouses, saunas, or industrial laundries, where condensation and steam are constant. This versatility makes IP68 waterproof neon strip lights suitable for both indoor and outdoor use, eliminating the need for separate lighting solutions for wet and dry areas.

The ability of IP68 waterproof neon strip lights to withstand extreme moisture stems from meticulous construction that seals every vulnerable component. Full encapsulation is the cornerstone of their design, with the entire strip—LEDs, circuit board, and wiring—encased in a thick, flexible layer of waterproof material, typically high-grade silicone or polyurethane. This encapsulation creates a seamless barrier that prevents water from reaching any internal parts, even under pressure. The material is chosen for its flexibility, allowing the strip to bend around corners or wrap around objects without cracking the seal, and its resistance to UV degradation, ensuring it doesn’t become brittle or yellow when exposed to sunlight.

Reinforced connections eliminate weak points where water could enter. The power leads and any splices are sealed with heat-shrink tubing or molded rubber connectors, creating a bond that’s as strong as the main encapsulation. These connections are tested to withstand the same submersion conditions as the strip itself, ensuring no water intrusion at junctions—a common failure point in lower-rated waterproof lights. For longer installations requiring multiple strips, specialized waterproof connectors maintain the IP68 rating across joins, allowing for extended lengths without compromising protection.

Durable circuit boards form the foundation, designed to resist corrosion even if water were to breach the outer seal (though the encapsulation makes this highly unlikely). The boards are coated with a conformal layer—a thin, protective film that repels moisture and prevents oxidation of the metal components. This secondary protection adds a layer of security, ensuring the strip remains functional even in the rare event of minor seal damage. The LEDs themselves are also water-resistant, with components rated for use in wet environments, further enhancing the strip’s reliability.

Mechanical strength ensures the strip withstands physical stress in harsh environments. The encapsulation material is resistant to abrasion, chemicals, and temperature extremes, making the strip suitable for use in industrial settings with cleaning agents, saltwater (marine environments), or fluctuating temperatures (from freezing to hot climates). This durability prevents damage from handling during installation, exposure to rough surfaces, or contact with chemicals, ensuring the waterproof seal remains intact over time.

IP68 waterproof neon strip lights excel in environments where water is a constant presence, offering reliable illumination in settings that would disable standard lighting. Aquatic environments are a primary application, with strips used to illuminate swimming pools, hot tubs, and ponds. Submerged along pool edges or installed in underwater niches, they create vibrant, color-changing effects that enhance nighttime swimming and transform the pool into a focal point. In ponds or water features, they highlight aquatic plants, fish, or cascading water, adding visual interest without the risk of water damage. The strips’ flexibility allows them to follow the curves of pool walls or pond liners, ensuring even light distribution.

Marine and coastal settings benefit from their resistance to saltwater and harsh weather. Boat owners use IP68 strips to illuminate decks, hulls, or interior wet spaces like galleys or heads, where salt spray and splashes are inevitable. Coastal homes and businesses install them along docks, piers, or beachfront patios, withstanding ocean mist, high winds, and rainstorms. The UV resistance of the encapsulation material prevents degradation from intense sunlight, ensuring long-term performance in bright, coastal climates.

Industrial and commercial wet areas rely on IP68 strips for durable lighting. Food processing facilities use them in washdown zones, where equipment is regularly cleaned with high-pressure water and sanitizing chemicals—the strip’s chemical resistance and waterproofing ensure it survives daily cleaning. Car washes install them to illuminate tunnels or cleaning bays, withstanding constant water spray and soap exposure. Greenhouses and hydroponic farms use them in high-humidity growing areas, where condensation and irrigation water would damage standard lights.

Outdoor extreme environments demand the reliability of IP68 waterproofing. They illuminate outdoor signs in rainy or snowy regions, ensuring visibility regardless of weather conditions. They line walkways, stairs, or building exteriors in areas prone to flooding, providing safety lighting even when submerged. Festivals or events held in wet weather use them for temporary installations, from stage backdrops to pathway lighting, avoiding the need for frequent replacements due to moisture damage.

Installing IP68 waterproof neon strip lights requires attention to detail to maintain their protective rating, though their design simplifies many common challenges. Surface preparation focuses on ensuring a secure bond for mounting. While the strips are often heavy due to their thick encapsulation, many feature a strong, waterproof adhesive backing that adheres to clean, smooth surfaces like tile, metal, or plastic. For rough or porous surfaces (like concrete or stone), mechanical fasteners—such as stainless steel clips or screws with waterproof gaskets—provide a secure hold without damaging the strip’s casing. These fasteners are spaced to prevent sagging, which could create gaps in light distribution.

Submersion considerations are critical for underwater installations. The strip must be fully submerged only if specified by the manufacturer, with attention to depth limits. For pool or pond installations, the strip should be mounted in a way that avoids direct contact with swimmers or debris, such as in a recessed channel or behind a protective grate. This prevents physical damage to the strip and ensures even light distribution. Wiring from the strip to the power supply must be routed through waterproof conduits or channels, keeping connections above water whenever possible to minimize risk.

Power supply protection is essential, as standard power supplies are not waterproof. The transformer or driver must be mounted in a dry, protected location—like a weatherproof junction box or indoor cabinet—and connected to the strip via waterproof cables. For underwater installations, the power supply should be positioned well above the waterline, with cables sealed at entry points to prevent moisture from traveling along wires into the supply. Some manufacturers offer waterproof power supplies rated for outdoor or wet locations, providing an extra layer of safety in exposed areas.

Custom lengths and joins require specialized techniques to maintain IP68 ratings. While some strips can be cut to length at pre-marked lines, the cut end must be sealed immediately with waterproof epoxy or a manufacturer-provided end cap to prevent water intrusion. Joining multiple strips requires waterproof connectors designed for IP68 use, which lock into place and create a sealed bond between segments. These connectors are often tool-free, allowing for quick installation while ensuring the join is as waterproof as the rest of the strip.

IP68 waterproof neon strip lights are designed for minimal maintenance, but proactive care ensures they remain reliable in harsh environments. Cleaning protocols focus on removing debris that could obscure light output. For underwater strips, algae or mineral deposits may accumulate over time; these can be removed with a soft brush or cloth, avoiding abrasive tools that could scratch the encapsulation. For outdoor strips, rinsing with a hose (on low pressure) removes dirt, pollen, or salt buildup, preserving brightness. Chemical cleaners should be avoided unless specifically recommended by the manufacturer, as harsh substances could degrade the silicone or polyurethane casing.

Inspection for damage is crucial, especially after extreme events like storms or flooding. Check for cracks, tears, or punctures in the encapsulation, paying close attention to connections and cut ends. Even minor damage can compromise waterproofing, so any issues should be addressed immediately with waterproof sealant or by replacing the affected segment. For underwater strips, check that mounting hardware remains secure, as shifting could cause the strip to rub against surfaces and damage the casing.

Electrical connection checks prevent moisture-related failures. Inspect power leads and connectors for signs of corrosion, which can indicate a compromised seal. If corrosion is present, the connector should be replaced with a new waterproof model. Ensure that cables are not stretched or kinked, as this can damage internal wiring or loosen connections over time. For smart or controlled strips, check that controllers remain dry and functional, as these components are often not waterproof and require separate protection.

Lifespan considerations are extended compared to non-waterproof lights, thanks to their robust construction. The LEDs themselves have a long operational life, often tens of thousands of hours, even in continuous use. The encapsulation material resists degradation from UV light, chemicals, and temperature fluctuations, ensuring the strip remains waterproof for years. In marine or industrial environments, where exposure to salt or chemicals is high, periodic checks for material degradation are recommended, with replacement of segments if the casing becomes brittle or discolored.

The market for IP68 waterproof neon strip lights continues to evolve, with innovations focusing on enhanced performance, smart integration, and sustainability. Smart waterproof controllers are emerging, allowing for remote control of IP68 strips via waterproof remotes or app-based systems. These controllers enable color changes, dimming, or effect adjustments even for underwater strips, expanding creative possibilities for pools, fountains, or marine settings. Some models feature wireless connectivity, eliminating the need for wired controllers near water and enhancing safety.

Energy efficiency is a growing focus, with manufacturers developing IP68 strips using low-power LEDs that reduce energy consumption without sacrificing brightness. This is particularly valuable for underwater applications, where lights may remain on for extended periods, as lower power usage reduces heat buildup and extends lifespan. Solar-powered IP68 systems are also being developed for outdoor use, with waterproof solar panels and batteries enabling off-grid lighting in remote wet areas like docks or nature reserves.

Material innovations are improving durability and flexibility. New encapsulation materials offer better resistance to chemicals, salt, and extreme temperatures, making strips suitable for even harsher environments—such as industrial chemical plants or polar research stations. Thinner, more flexible casings maintain waterproofing while allowing for tighter bends, expanding design possibilities for intricate underwater or architectural installations.

Custom color and effect options are becoming more sophisticated, with IP68 strips offering RGBW (Red, Green, Blue, White) capabilities for enhanced color mixing, including true white light. This allows for seamless transitions between colored and white lighting, ideal for applications like pool lighting that needs to shift from vibrant party colors to bright safety lighting. Programmable effects, such as synchronized color changes across multiple strips, enable coordinated displays in large water features or marine events.

IP68 waterproof neon strip lights have redefined what’s possible in wet and submerged lighting, offering unparalleled protection without compromising on flexibility or performance. Their ability to thrive in pools, marine environments, industrial washdown areas, and extreme outdoor conditions makes them indispensable for anyone seeking reliable illumination in moisture-rich settings. Whether creating a stunning underwater light show, ensuring safety in a flood-prone area, or powering signage in a rainy climate, these strips deliver consistent, vibrant light where standard lighting would fail.

As technology advances, IP68 waterproof neon strip lights will continue to push boundaries, offering smarter controls, greater efficiency, and expanded applications. For professionals and enthusiasts alike, they represent the ultimate solution for lighting in wet environments—proving that with the right engineering, water and electricity can coexist safely and beautifully.