Time:2025-08-14

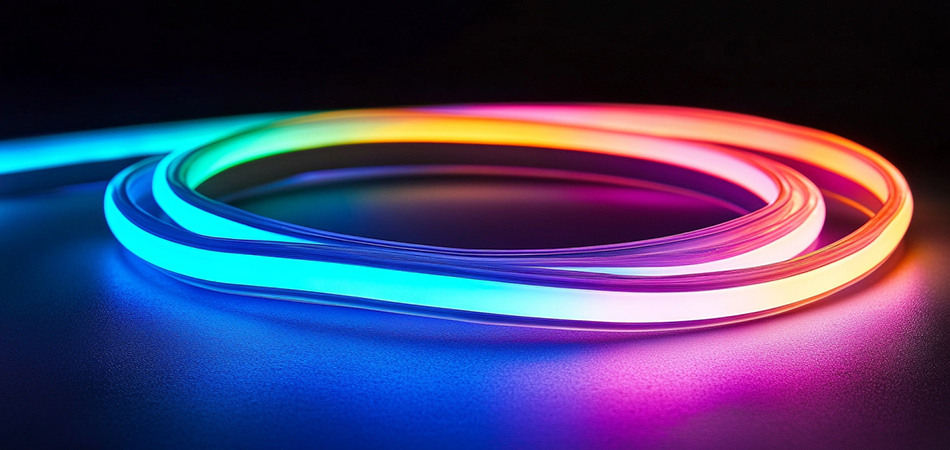

Waterproof Silicone Neon Light Strip emerges as a specialized solution designed to thrive in environments where moisture is a constant presence. These strips combine the vibrant glow of neon lighting with advanced waterproofing technologies, making them indispensable for spaces like bathrooms, pools, outdoor patios, and industrial facilities. Unlike standard neon strips that falter when exposed to water, Waterproof Silicone Neon Light Strip maintains consistent performance even in wet or humid conditions, expanding the possibilities of where neon-style lighting can be applied. This article explores their waterproofing mechanisms, material engineering, application versatility, installation protocols, and maintenance practices, highlighting how they redefine durability in illuminated design.

The core strength of Waterproof Silicone Neon Light Strip lies in its multi-layered approach to moisture resistance, ensuring internal components remain protected even in harsh conditions. Seamless silicone extrusion forms the first line of defense, creating a continuous, airtight casing around the LEDs and circuit board. This extrusion process eliminates seams or gaps where water could infiltrate, unlike strip lights with glued or clamped casings that may develop leaks over time. The silicone itself is inherently water-repellent, further preventing moisture from penetrating the surface.

Encapsulated electronics add an extra layer of protection, with critical components like LEDs, resistors, and solder points coated in a waterproof resin. This encapsulation ensures that even if the outer silicone casing sustains minor damage, the internal electronics remain shielded from water, reducing the risk of short circuits or corrosion. This dual protection system—outer silicone casing plus encapsulated components—makes the strips suitable for submersion in shallow water, such as around pool edges or fountains.

IP rating compliance is a key indicator of their waterproof capabilities. These strips typically carry high Ingress Protection ratings, with IP65 offering protection against low-pressure water jets (ideal for outdoor patios), IP67 resisting temporary submersion, and IP68 designed for prolonged underwater use. These ratings are not arbitrary; they result from rigorous testing, ensuring the strips meet international standards for water and dust resistance.

Corrosion-resistant conductors prevent degradation of the circuit board’s metal pathways. Traditional copper traces can corrode in moist environments, leading to reduced conductivity or failure. Waterproof Silicone Neon Light Strip uses tinned copper or gold-plated conductors that resist oxidation, ensuring reliable electrical flow even when exposed to humidity or saltwater—critical for coastal applications or indoor spaces with high moisture levels like saunas.

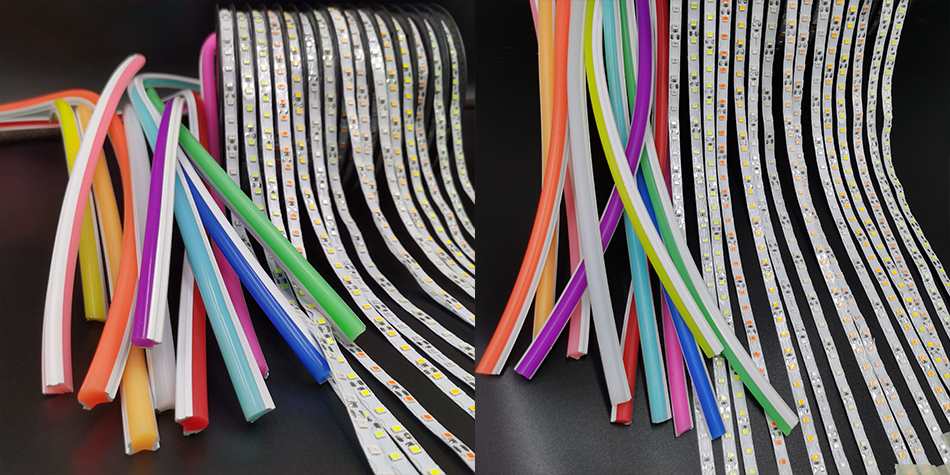

The silicone used in these strips is not ordinary; it is engineered to balance flexibility, durability, and water resistance. High-grade vulcanized silicone is chosen for its exceptional properties, including resistance to water, UV radiation, and temperature extremes. Vulcanization—a chemical process that cross-links polymer chains—enhances the silicone’s tensile strength, making it less likely to tear or puncture when bent or exposed to physical stress. This durability ensures the casing remains intact even in high-traffic areas or harsh outdoor conditions.

Flexibility without compromise allows the strips to conform to curves and corners while maintaining their waterproof seal. Unlike rigid waterproof lighting fixtures that limit installation options, these strips can be bent around pool edges, wrapped around outdoor furniture, or mounted on irregular surfaces like stone walls. The silicone retains its flexibility in freezing temperatures, preventing cracking that could compromise water resistance, and remains stable in high heat, avoiding warping or melting.

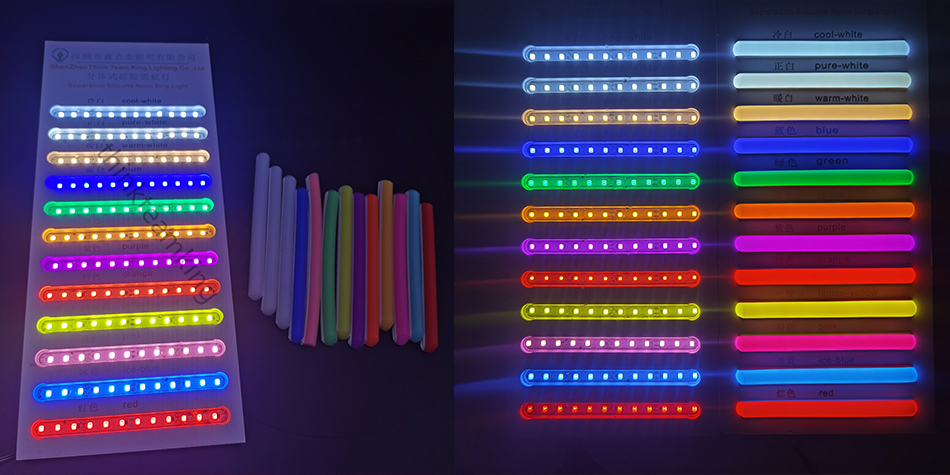

Translucency optimization ensures the silicone casing diffuses light effectively without sacrificing waterproofing. The material is formulated to be highly clear, allowing maximum light transmission while softening the LED glow to mimic the smooth appearance of traditional neon. This clarity is maintained over time, as the silicone resists yellowing from UV exposure—a common issue with cheaper plastics that can dull light output and reduce aesthetic appeal.

Chemical resistance makes the strips suitable for environments with cleaning agents or harsh substances. In commercial kitchens, for example, they may be exposed to grease or sanitizing solutions, while outdoor strips might encounter pesticides or salt spray. The silicone casing repels these chemicals, preventing degradation and ensuring long-term performance in specialized settings.

Waterproof Silicone Neon Light Strip’s ability to withstand moisture opens up a range of applications that would be off-limits to standard lighting. Residential wet areas benefit significantly, with bathrooms using them around mirrors, along shower enclosures, or behind bathtubs to add ambient light without safety risks. Kitchens install them under sinks or around backsplashes near faucets, where splashes are common. Pools and hot tubs feature them along edges or underwater ledges, creating stunning nighttime effects while withstanding constant exposure to chlorinated or saltwater.

Outdoor environments are ideal for these strips, which illuminate gardens, patios, and pathways regardless of rain, snow, or dew. They outline rooflines, deck railings, and pergolas, transforming outdoor spaces into usable areas after dark. Garden ponds and water features use submersible variants to highlight aquatic plants or create reflective light effects on the water’s surface. Even in coastal regions, where salt spray is prevalent, the strips resist corrosion, maintaining their appearance and functionality.

Commercial and industrial settings rely on their durability in demanding conditions. Restaurants use them in outdoor dining areas, around bars with frequent spills, or in walk-in refrigerators where condensation is common. Industrial facilities install them in warehouses with high humidity, car washes with constant water spray, or food processing plants requiring frequent cleaning with water and chemicals. Marine environments, such as boat decks or docks, use them to enhance safety and visibility in saltwater conditions.

Recreational and event spaces leverage their versatility for temporary or permanent installations. Water parks incorporate them into slides or pool areas, while event planners use them for outdoor weddings, festivals, or concerts where weather conditions are unpredictable. Their waterproof nature ensures the show goes on, even if rain interrupts the event.

Proper installation is critical to maintaining the waterproof integrity of these strips. Surface preparation focuses on creating a clean, dry base that promotes adhesion and prevents water from pooling under the strip. For non-porous surfaces like tile, glass, or metal, wiping with isopropyl alcohol removes oils and debris. Porous surfaces such as concrete or stone may require sealing with a waterproof primer to prevent moisture from seeping through and loosening the strip’s adhesive.

Cutting and sealing must be done with precision to avoid compromising water resistance. Most strips feature pre-marked cut lines, and cutting outside these lines can damage the circuit board. After cutting, applying a waterproof end cap or silicone sealant to the exposed end creates a barrier against moisture. This step is non-negotiable; even a small gap can allow water to enter, leading to long-term damage.

Mounting methods vary by environment, but all prioritize maintaining the strip’s waterproof seal. The built-in adhesive—usually a marine-grade, waterproof variant—works well for smooth surfaces. For vertical installations, high-traffic areas, or underwater use, mechanical fasteners like stainless steel clips or screws are recommended. These fasteners should be spaced evenly to avoid stretching the silicone casing, which could create gaps. When mounting underwater, ensuring the strip is fully submerged only to its rated depth (per IP classification) prevents overexposure.

Connector handling requires waterproof solutions to avoid weak points. Standard connectors are not sufficient; instead, using IP-rated waterproof connectors with rubber gaskets ensures a tight seal between strip segments. These connectors are often screw-on or compression-fit, creating a barrier that resists water intrusion. For permanent installations, soldering connections and then sealing with waterproof heat-shrink tubing adds an extra layer of protection.

Power supply placement is strategic to keep electronics dry. While the strips themselves are waterproof, their power supplies are not. Mounting power supplies in weatherproof enclosures, elevated above ground, or indoors (with wiring run through waterproof conduits) prevents water damage. For underwater applications, using a transformer rated for wet locations and ensuring all connections are above water level minimizes risk.

Maintaining Waterproof Silicone Neon Light Strip is straightforward, but attention to detail ensures long-term reliability. Regular cleaning removes substances that can degrade the silicone or block light output. For most environments, a soft cloth dampened with mild soap and water is sufficient. In areas with heavy grime—like industrial kitchens or pool surrounds—a soft brush can dislodge debris without scratching the silicone. Avoiding harsh chemicals like bleach or solvents prevents damage to the casing.

Inspection for damage is crucial after severe weather or physical impact. Checking for cracks, tears, or punctures in the silicone casing allows for prompt repairs. Small cracks can be sealed with a waterproof silicone sealant that matches the strip’s flexibility, ensuring the repair moves with the strip without reopening. Damaged sections should be cut out at the nearest cut line, with the new end sealed properly.

Connection checks prevent moisture intrusion at weak points. Over time, connectors can loosen or gaskets can degrade, creating gaps. Periodically inspecting connectors and tightening them (if screw-on) or replacing worn gaskets maintains their waterproof seal. For soldered connections, checking for corrosion around the joint and reapplying sealant if needed ensures continued protection.

Seasonal adjustments help the strips withstand extreme conditions. In winter, removing snow or ice buildup prevents excessive weight from stretching the casing. In coastal areas, rinsing the strips with fresh water periodically removes salt residue that can accelerate corrosion. For underwater strips, checking water chemistry (e.g., chlorine or pH levels in pools) ensures chemicals do not degrade the silicone over time.

Even with robust design, occasional issues may arise, and targeted troubleshooting resolves them effectively. Flickering or dimming often indicates water intrusion at a connection point. Inspecting connectors, resealing with silicone, or replacing damaged connectors typically restores functionality. In severe cases, checking for corrosion on the circuit board (visible through a damaged casing) may require replacing the affected strip section.

Adhesive failure in wet areas can occur if the surface was not properly prepared or if the adhesive is exposed to prolonged submersion. Removing the strip, cleaning the surface thoroughly, and reapplying with a waterproof adhesive (or mechanical fasteners) resolves this. For underwater installations, using epoxy-based adhesives designed for wet surfaces ensures a secure bond.

Color inconsistency in RGB strips may result from water damage to the controller or wiring. Testing the controller with a dry strip identifies if it is the source of the issue. If wiring is suspect, replacing with waterproof-rated cables and connectors often fixes color mixing problems.

Reduced brightness over time in outdoor strips could be due to UV degradation of the silicone casing, causing it to yellow. While high-grade silicone resists this, prolonged exposure in intense sunlight may eventually dull the casing. Replacing the strip with a UV-stabilized variant restores light output.

The market for Waterproof Silicone Neon Light Strip continues to evolve, driven by demand for more durable and versatile wet-area lighting. Smart waterproof systems are emerging, with strips featuring Bluetooth or Wi-Fi connectivity that allows control via apps, even in wet environments. These smart strips can sync with music, adjust brightness based on ambient light, or follow schedules—enhancing convenience in spaces like outdoor patios or pool areas.

Eco-friendly materials are gaining traction, with manufacturers developing silicone casings made from recycled or plant-based materials that maintain waterproof properties. These sustainable options appeal to environmentally conscious consumers and businesses, reducing the product’s carbon footprint without compromising performance.

Enhanced submersible capabilities are being pushed further, with new designs targeting deeper water applications, such as decorative lighting in ponds or aquariums. These strips feature reinforced casings and specialized adhesives that withstand higher water pressure, expanding their use in aquatic environments.

Integrated sensors are being added to some models, allowing the strips to respond to water presence or temperature changes. For example, strips near pools could brighten when motion is detected in the water, enhancing safety, or dim in response to high humidity to save energy.

Waterproof Silicone Neon Light Strip has transformed the way we light wet and humid environments, offering a blend of safety, durability, and aesthetic appeal that was previously unavailable. By combining advanced waterproofing technologies with high-grade silicone engineering, these strips provide reliable illumination in spaces where standard lighting would fail—from bathroom showers to underwater pool features.

Their versatility, ease of installation, and low maintenance requirements make them a practical choice for both residential and commercial applications, while ongoing innovations continue to expand their capabilities. As demand for functional, durable lighting in wet areas grows, Waterproof Silicone Neon Light Strip remains at the forefront, proving that moisture and light can coexist harmoniously to create stunning, long-lasting illuminated spaces.