Time:2025-08-13

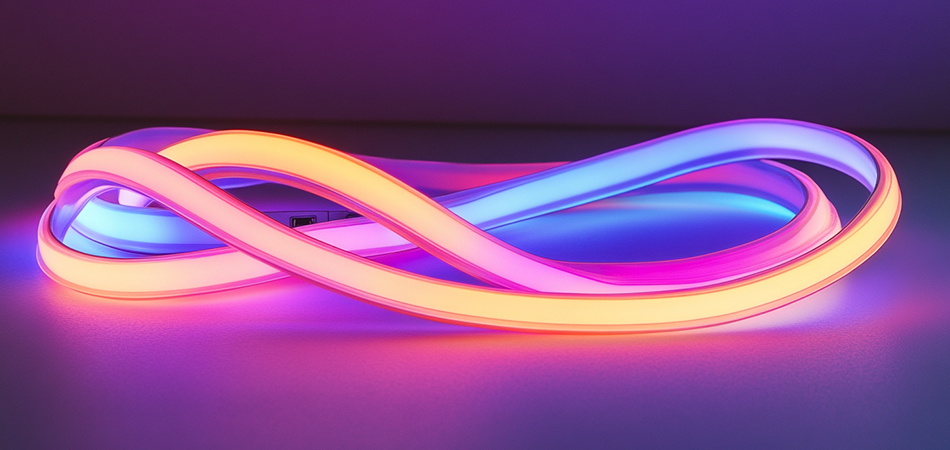

Silicone Neon LED Strip represents a harmonious integration of two powerful technologies—flexible silicone casings and high-performance LEDs—resulting in a lighting solution that excels in both form and function. These strips have become a cornerstone of contemporary lighting design, offering the vivid glow associated with traditional neon while delivering the efficiency, durability, and versatility that modern applications demand. Unlike glass neon tubes that are fragile and energy-intensive, or basic LED strips lacking protective enclosures, Silicone Neon LED Strip combines the best of both worlds: the soft, diffused light of neon with the resilience and adaptability of silicone and LED technology. This article explores their composite structure, performance dynamics, application breadth, comparative advantages, and maintenance essentials, highlighting how they have become a preferred choice for lighting professionals and enthusiasts alike.

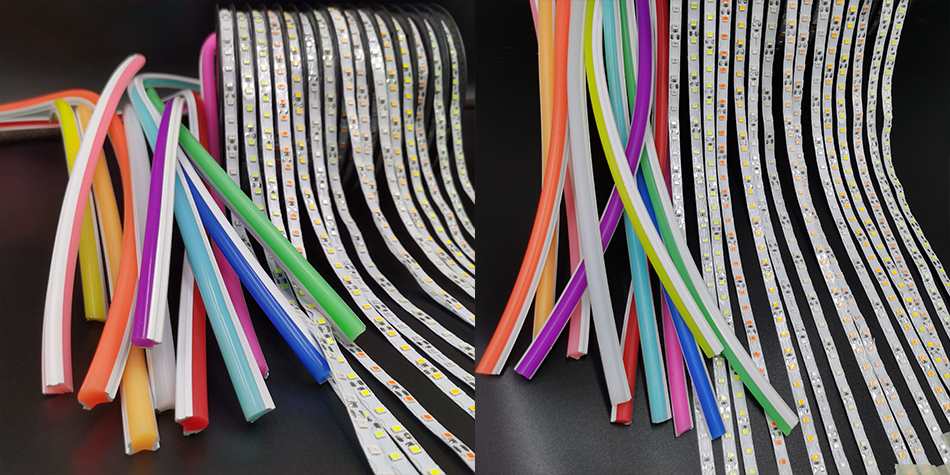

The exceptional performance of Silicone Neon LED Strip stems from its layered elaborate design structure, each component working in tandem to deliver optimal results. At the core is a flexible circuit board crafted from materials like polyimide, which provides a sturdy yet bendable foundation for the LEDs. This board is engineered to withstand repeated flexing without compromising electrical conductivity, allowing the strip to conform to curves, corners, and irregular surfaces with ease. The circuit pathways are printed with precision to ensure uniform power distribution, a critical factor in maintaining consistent light output across the entire length of the strip.

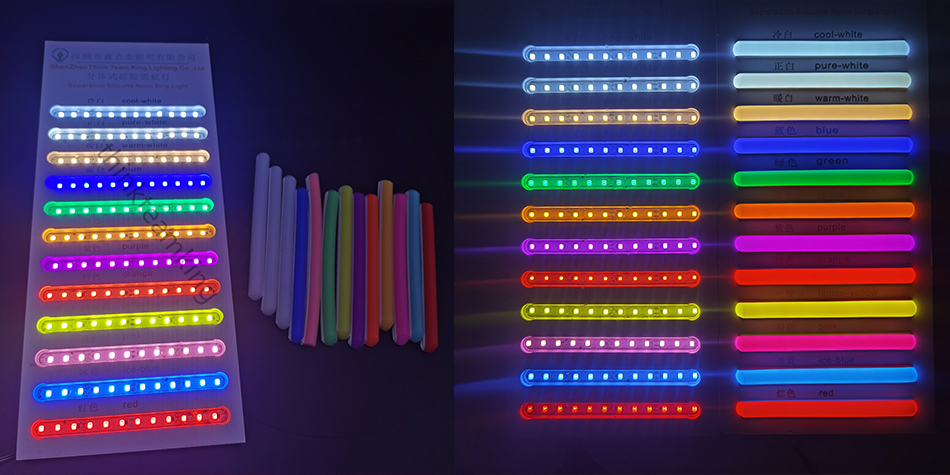

Mounted on the circuit board are high-quality LEDs, selected for their luminous efficiency and color accuracy. These LEDs are available in a range of configurations, including single-color options (warm white, cool white, and saturated hues) and multi-color variants (RGB and RGBW), offering versatility to suit any lighting need. The diodes are spaced strategically to eliminate visible "dots" of light, creating a smooth, continuous glow that mimics the appearance of traditional neon. Advanced models may include LEDs with enhanced heat dissipation properties, ensuring stable performance even during prolonged use.

Enveloping the circuit board and LEDs is a silicone casing that serves as both protector and light diffuser. This casing is extruded in a seamless process, forming a tight seal around the internal components to shield them from moisture, dust, and physical impact. The silicone is formulated to be highly translucent, allowing light to pass through while softening its intensity to create a gentle, ambient glow. Its flexibility matches that of the circuit board, enabling the strip to bend to tight radii without cracking or compromising the seal—an essential feature for creative installations.

Reinforced edges along the length of the strip add structural integrity, preventing fraying or tearing at the most vulnerable points. These edges are slightly thicker than the main casing, providing additional support during installation and use. They also help to maintain the strip’s shape when mounted on vertical or irregular surfaces, ensuring a neat, professional finish.

Silicone Neon LED Strip delivers impressive performance metrics that make it suitable for diverse lighting scenarios, combining light quality with robust resilience. Luminous efficiency is a standout feature, with LEDs converting a high percentage of electrical energy into visible light rather than heat. This results in bright, vibrant illumination with lower energy consumption compared to traditional neon or incandescent lighting, reducing both operational costs and environmental impact. The silicone casing enhances this efficiency by directing light outward rather than allowing it to scatter, ensuring that most of the light produced is utilized effectively.

Color stability is another key performance attribute, with LEDs maintaining consistent hues over time and across varying temperatures. Unlike traditional neon, which can shift color due to temperature changes or gas degradation, Silicone Neon LED Strip retains its color accuracy, making it ideal for applications where color consistency is critical—such as brand-specific lighting or art installations. The silicone casing itself is tint-free, ensuring that it does not alter the LED color, even after prolonged exposure to light.

Environmental resilience sets these strips apart from unprotected LED solutions. The silicone casing provides resistance to water, dust, and UV radiation, allowing the strip to perform reliably in both indoor and outdoor environments. It can withstand temperature extremes, remaining flexible in freezing conditions and stable in high heat, making it suitable for use in climates ranging from cold northern regions to hot, sunny areas. This resilience ensures that the strip maintains its performance and appearance for years, even in challenging conditions.

Mechanical durability ensures that the strip can withstand the rigors of installation and daily use. It is resistant to impact, abrasion, and bending, making it less likely to be damaged during handling or by accidental bumps. This durability reduces the need for frequent replacements, lowering maintenance costs and ensuring long-term reliability.

Silicone Neon LED Strip’s versatility allows it to shine in a wide range of applications, from subtle ambient lighting to bold, statement-making installations. Residential interiors benefit from its ability to add warmth and character to living spaces. In living rooms, it can be installed behind TVs, along bookshelves, or under couches to create a cozy, inviting atmosphere. Bedrooms use it as soft accent lighting, with strips placed under beds or along ceiling edges to provide gentle illumination without disrupting sleep. Kitchens and bathrooms leverage its moisture resistance, with strips installed under cabinets or around mirrors to enhance visibility and style.

Commercial spaces utilize Silicone Neon LED Strip to attract customers and enhance brand identity. Retail stores install it in window displays, along aisles, or behind merchandise to highlight products and guide foot traffic. Restaurants and cafes use it to create ambiance—warm white strips for intimate dining areas, or colored strips to match thematic decor. Office spaces incorporate it into workstations or meeting rooms, providing task lighting that reduces eye strain and boosts productivity.

Architectural and exterior lighting showcases the strip’s durability and adaptability. It can be used to outline building facades, highlight architectural features, or illuminate pathways, transforming structures into striking nighttime landmarks. Outdoor patios, decks, and gardens benefit from its weather resistance, with strips placed along railings, around pools, or within landscaping to extend usable space into the evening. Events such as weddings, festivals, and trade shows use it to create temporary installations, adding flair to stages, tents, and display areas.

Artistic and decorative applications unlock the creative potential of Silicone Neon LED Strip. Artists integrate it into sculptures, installations, and mixed-media works, using its glow to add depth and dimension. Sign makers rely on its flexibility to create custom logos, lettering, and designs for storefronts, replacing traditional neon with a more durable, cost-effective alternative. This versatility allows for unique, eye-catching creations that stand out in any setting.

Silicone Neon LED Strip offers distinct advantages over other lighting solutions, making it a superior choice for many applications. Durability surpasses traditional neon, which is fragile and prone to breakage. The silicone casing protects the LEDs and circuitry from impact, moisture, and environmental damage, ensuring a longer lifespan and reducing maintenance costs. This durability makes it suitable for high-traffic areas, outdoor use, and settings where traditional neon would be impractical.

Energy efficiency outperforms both traditional neon and incandescent lighting, with lower power consumption and longer LED lifespans. This reduces electricity bills and minimizes the need for replacements, making it a cost-effective choice for long-term use. Its efficiency also aligns with growing sustainability goals, reducing carbon footprints and energy waste.

Flexibility and adaptability exceed rigid lighting fixtures and even some LED strips. Silicone Neon LED Strip can be cut to custom lengths, bent around curves, and mounted on irregular surfaces, allowing for creative installations that follow the natural lines of a space. This adaptability eliminates the need for multiple fixtures, simplifying design and reducing visual clutter.

Light quality is superior to bare LED strips, which can produce harsh, uneven light. The silicone casing diffuses the LED light to create a smooth, uniform glow that enhances ambiance without glare. This makes it suitable for both functional lighting (such as task lighting) and decorative lighting (such as accent lighting), providing versatility that many other solutions lack.

Proper installation is essential to maximizing the performance and longevity of Silicone Neon LED Strip. Surface preparation is the first step, as a clean, dry surface ensures a secure bond. For indoor applications, wiping the surface with isopropyl alcohol removes dust, oils, and debris, allowing the strip’s adhesive backing to adhere firmly. For outdoor or porous surfaces—such as brick, stone, or wood—a primer may be applied to enhance adhesion, preventing the strip from lifting over time.

Cutting and connecting require attention to detail to maintain functionality. Most strips feature pre-marked cut lines that indicate where they can be trimmed without damaging the circuitry. Cutting outside these lines can disrupt the circuit and render the strip inoperable. When connecting multiple strips, using compatible connectors ensures a secure, reliable connection. Waterproof connectors are essential for outdoor or high-moisture installations, preventing moisture from entering the connection point.

Mounting options vary depending on the surface and application. The strip’s built-in adhesive works well for smooth, flat surfaces like painted walls, glass, or metal. For rough, vertical, or high-traffic areas, mechanical fasteners such as clips or screws provide additional security. These fasteners should be made from corrosion-resistant materials (like stainless steel) for outdoor use, ensuring they do not degrade over time.

Power supply integration is critical to ensuring stable performance. Using a power supply that matches the strip’s voltage requirements prevents underpowering (which can cause dim light) or overpowering (which can damage the LEDs). For longer strips, adding power injectors at intervals ensures that voltage remains consistent across the entire length, preventing dimming at the far end. The power supply should be mounted in a dry, sheltered location, especially for outdoor installations, to protect it from the elements.

Maintaining Silicone Neon LED Strip is simple, with minimal effort required to keep it performing at its best. Regular cleaning removes dust, dirt, and debris that can dull light output. A soft, dry cloth or a slightly damp microfiber cloth is sufficient for wiping down the silicone casing, taking care to avoid excessive moisture around connections. For outdoor strips, a gentle rinse with water can remove pollen, dirt, or other outdoor debris, followed by drying with a cloth to prevent water spots.

Inspection for damage helps catch issues early, before they affect performance. Checking for cracks in the silicone casing, loose connections, or damaged LEDs allows for prompt repairs. Small cracks can be sealed with clear silicone sealant to prevent moisture intrusion, while damaged sections can be cut off at the nearest cut line and replaced. This modular design ensures that the remaining strip continues to function properly.

Connection maintenance ensures reliable performance, especially in outdoor or high-moisture environments. Periodically inspecting connectors and ensuring they are tight and sealed prevents moisture from entering and causing corrosion. For outdoor installations, reapplying waterproof sealant around connections can extend their lifespan and prevent failures.

Environmental protection helps preserve the strip’s performance in challenging conditions. Avoiding exposure to harsh chemicals—such as cleaning agents or solvents—prevents damage to the silicone casing. In outdoor settings, ensuring the strip is not in direct contact with standing water or excessive moisture (even though it is water-resistant) can extend its lifespan. For strips in direct sunlight, periodic checks for UV degradation (such as yellowing) allow for timely replacement if needed.

Silicone Neon LED Strip is generally reliable, but occasional issues can be resolved with simple troubleshooting. Dimming or uneven light is often caused by voltage drop in long strips, loose connections, or a faulty power supply. Adding a power injector, tightening connections, or replacing the power supply typically resolves this issue.

Color inconsistency in multi-color strips may result from a malfunctioning controller, loose connections, or uneven LED wear. Resetting the controller, checking and securing connections, or recalibrating the colors can restore uniformity. In some cases, replacing a small section of the strip may be necessary if individual LEDs are faulty.

Adhesive failure can occur if the surface was not properly prepared or if the strip is exposed to extreme temperatures. Removing the strip, cleaning the surface thoroughly, and reapplying with fresh adhesive or mechanical fasteners resolves this issue. For permanent installations, screws or clips are more reliable than adhesive alone.

Water damage in outdoor strips may cause flickering or failure, usually due to compromised seals at connections or cuts. Reapplying waterproof sealant or replacing damaged connectors can restore functionality. In severe cases, replacing the affected section of the strip ensures continued performance.

Future Trends: Innovations in Silicone Neon LED Technology

The evolution of Silicone Neon LED Strip continues, with ongoing innovations enhancing its capabilities and expanding its applications. Smart integration is a key trend, with strips increasingly featuring Bluetooth, Wi-Fi, or Zigbee connectivity. This allows for remote control via apps, voice assistants, or home automation systems, enabling users to adjust brightness, change colors, or set schedules with ease. Advanced models may include sensors that adjust lighting based on ambient conditions, further optimizing energy use.

Material advancements are improving durability and performance, with new silicone formulations offering enhanced UV resistance, flexibility, and heat tolerance. These advances extend the strip’s lifespan, especially in harsh outdoor environments, reducing replacement frequency and environmental impact. Some manufacturers are also exploring eco-friendly materials, such as recycled silicone, to reduce the product’s carbon footprint.

Customization options are expanding, with manufacturers offering pre-cut shapes, custom colors, and even printable casings that allow for logos or patterns. This level of personalization enables unique, brand-specific installations that stand out in competitive markets. Additionally, modular designs that allow for easy upgrades or modifications are becoming more common, extending the strip’s useful life.

Energy efficiency continues to improve, with next-generation LEDs offering higher luminous efficacy and lower power consumption. This, combined with smart controls, makes Silicone Neon LED Strip an increasingly sustainable lighting option, aligning with global efforts to reduce energy use and greenhouse gas emissions.

Silicone Neon LED Strip has established itself as a versatile, reliable lighting solution that meets the demands of modern design. By combining the durability of silicone, the efficiency of LEDs, and the aesthetic appeal of neon, it offers a unique blend of performance and versatility that is unmatched by traditional lighting options. Whether used in residential, commercial, or outdoor settings, it transforms spaces with its vibrant, diffused light while withstanding the rigors of daily use and environmental challenges.

As technology continues to advance, Silicone Neon LED Strip will only become more capable, with enhanced smart features, improved materials, and greater customization options. For anyone seeking a lighting solution that balances form and function, durability and efficiency, Silicone Neon LED Strip is more than a practical choice—it is a versatile tool for creative expression, enhancing spaces and experiences with its warm, inviting glow.