Time:2025-08-12

Neon Led Strip Lights represent a harmonious fusion of the timeless allure of traditional neon and the practical advantages of LED technology. These strips have redefined how we illuminate spaces, offering the vibrant, nostalgic glow associated with neon while addressing its historical limitations—fragility, high energy consumption, and inflexibility. As lighting design continues to evolve toward versatility, sustainability, and customization, Neon Led Strip Lights have emerged as a cornerstone solution, catering to both residential and commercial needs. Whether used to add ambient warmth to a living room, create eye-catching signage for a storefront, or enhance outdoor landscapes, these strips deliver a unique combination of aesthetic appeal and functional performance. This article explores their structural composition, material innovations, installation flexibility, application diversity, and maintenance requirements, highlighting their role in shaping contemporary lighting design.

The performance of Neon Led Strip Lights is rooted in their carefully engineered structure, which balances form and function to deliver consistent, high-quality illumination. At the core lies a flexible circuit board, typically constructed from materials like polyimide that offer both durability and bendability. This board serves as the foundation, housing the electronic components that power the light-emitting diodes (LEDs) while allowing the strip to conform to various surfaces—from straight lines to gentle curves and tight corners. Unlike the rigid glass tubes of traditional neon, this flexible base enables versatile installation in spaces where conventional lighting would be impractical.

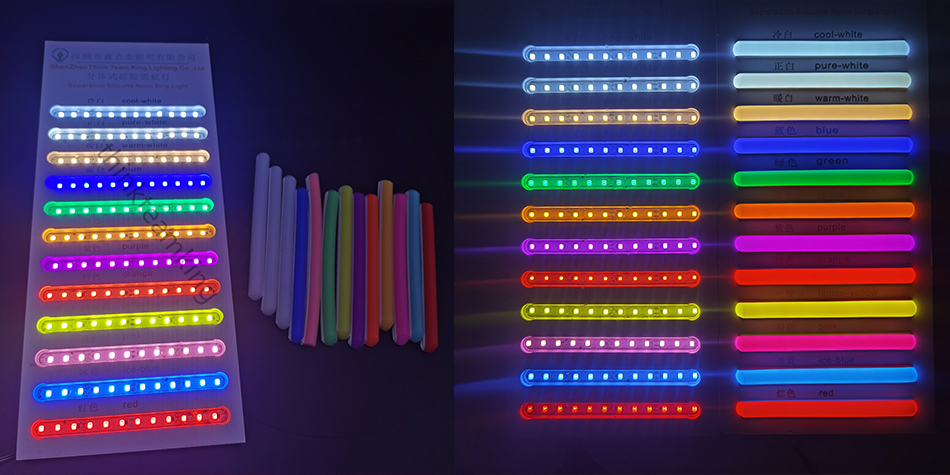

Embedded within the circuit board are high-performance LEDs, strategically positioned to ensure uniform light distribution. These LEDs are available in a spectrum of configurations, including single-color options (such as warm white, cool white, or bold primary hues), RGB (red-green-blue) for dynamic color mixing, and tunable white variants that adjust between warm and cool tones. The spacing of the LEDs is calibrated to eliminate the "dot effect" common in lower-quality strips, creating a seamless, continuous glow that closely mimics the soft radiance of traditional neon.

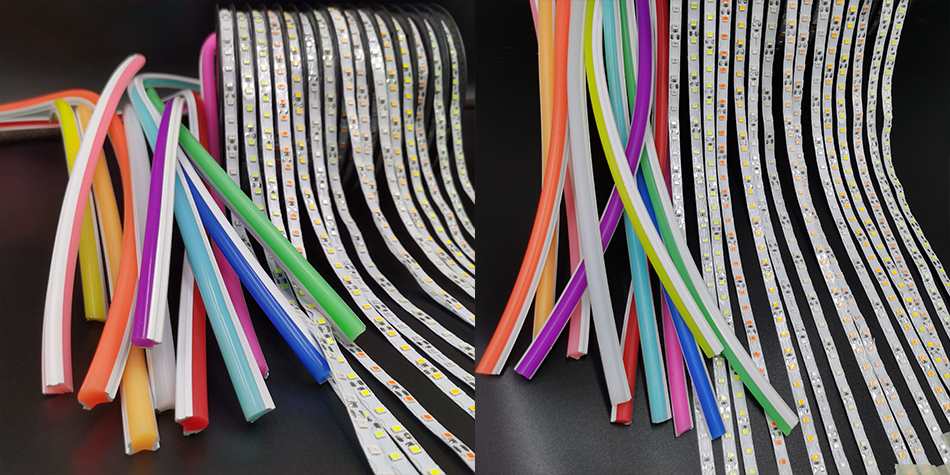

Encasing the circuit board and LEDs is a translucent protective layer, most commonly made from silicone or PVC. This casing serves multiple critical functions: it shields the internal components from dust, moisture, and physical damage; diffuses the light emitted by the LEDs to create a smooth, even glow; and enhances the strip’s flexibility. Silicone casings are particularly prized for their resistance to extreme temperatures, UV radiation, and water, making them ideal for outdoor or high-moisture environments. PVC casings, while more economical, offer reliable performance in indoor settings with moderate conditions.

Reinforced edges along the strip’s perimeter add an extra layer of durability, preventing fraying or tearing during installation or daily use. These edges are designed to withstand repeated bending without compromising the integrity of the casing or the circuit board, ensuring long-term reliability even in high-traffic areas.

The materials used in Neon Led Strip Lights are selected to optimize performance, durability, and adaptability to diverse environments. Silicone casings stand out for their exceptional properties, making them a preferred choice for demanding applications. They exhibit high heat resistance, allowing the strips to operate safely for extended periods without degrading. Their inherent water resistance makes them suitable for humid spaces like bathrooms, kitchens, and outdoor patios, while UV resistance ensures that their color and light output remain stable even under prolonged exposure to sunlight. Additionally, silicone’s elasticity enables the strip to bend and stretch without cracking, extending its lifespan in dynamic installations.

For indoor applications where cost is a consideration, PVC casings offer a practical alternative. They provide basic protection against dust and minor moisture, making them ideal for living rooms, bedrooms, and offices. Many PVC variants are treated with additives to improve flexibility and heat resistance, expanding their usability to settings like under-cabinet lighting in kitchens.

The LED technology itself is a key material innovation, offering significant advantages over the gas-filled tubes of traditional neon. LEDs consume a fraction of the energy, reducing electricity costs and environmental impact. They also have an impressive lifespan, often lasting tens of thousands of hours—far longer than traditional neon—minimizing the need for replacements. Furthermore, LEDs generate little heat, making the strips safer to touch and reducing the risk of fire when installed near flammable materials.

Conductive elements within the circuit board, such as copper traces, are engineered for flexibility and efficiency. These traces are printed in a pattern that allows them to bend without breaking, ensuring consistent electrical flow across the entire length of the strip. This reliability is essential for maintaining uniform light output, even when the strip is shaped into complex forms.

Neon Led Strip Lights are designed with user-friendly installation in mind, offering versatile options that cater to both DIY enthusiasts and professional installers. Adhesive backing is a standard feature, with high-strength, heat-resistant adhesive applied to the back of the strip. This allows for quick, tool-free mounting on smooth surfaces such as painted walls, glass, metal, and plastic. The adhesive is formulated to bond securely even when the strip is bent, ensuring a long-lasting hold in vertical, horizontal, or curved installations. For rough or textured surfaces—such as brick, stucco, or unfinished wood—mounting clips or brackets provide additional stability, with screws or nails securing the strip in place.

A cuttable design enhances versatility, with pre-marked cut lines at regular intervals along the strip. This allows users to trim the strip to the exact length required for their project, whether it’s a small accent under a shelf or a long strip outlining a room. After cutting, the exposed end can be sealed with a waterproof cap (included in most kits) to protect the circuit board from moisture, a critical step for outdoor or humid installations.

Connectable segments enable users to extend the strip’s length by linking multiple segments. Most strips feature male and female connectors that snap together securely, allowing for easy expansion without the need for soldering. This modular design simplifies large-scale projects, such as lighting commercial signage, wrapping around building facades, or outlining swimming pools. For permanent installations, solder pads are often provided, enabling a stronger, more seamless connection.

Power options are tailored to different applications. Most Neon Led Strip Lights operate on low voltage (typically 12V or 24V), requiring a power adapter that plugs into a standard electrical outlet. This low-voltage operation enhances safety, making the strips suitable for homes with children or pets. For larger commercial projects, hardwired power supplies can be integrated into the building’s electrical system by professionals, providing a clean, unobtrusive look.

Neon Led Strip Lights’ versatility makes them suitable for a wide range of applications, enhancing spaces with both functional and decorative lighting. Residential interiors benefit from their ability to add ambiance and style. In living rooms, strips can be installed behind TVs, along ceiling edges, or under furniture to create a cozy, inviting atmosphere. Bedrooms use them as soft nightlights, with strips under beds or behind headboards providing gentle illumination that doesn’t disrupt sleep. Kitchens and bathrooms leverage waterproof variants for under-cabinet lighting, mirror accents, or shower surrounds, combining functionality with modern design.

Commercial spaces utilize Neon Led Strip Lights to attract customers and reinforce brand identity. Retail stores install them in window displays, along shelving, or behind merchandise to highlight products and guide foot traffic. Restaurants and bars use them to set moods—warm white strips for intimate dining areas, or RGB strips that change color to match events or themes. Office spaces and coworking environments use them to define zones, with strips along desk edges or meeting room perimeters adding energy to otherwise sterile settings.

Outdoor areas are transformed by weather-resistant Neon Led Strip Lights. Homeowners use them to illuminate patios, decks, and garden pathways, creating an inviting outdoor living space for evening gatherings. Commercial properties like hotels, resorts, and event venues install them along building exteriors, pool edges, or outdoor dining areas to extend their aesthetic into outdoor spaces. Event planners rely on them for temporary setups, such as wedding backdrops, festival stages, or pop-up shops, thanks to their portability and easy installation.

Art and signage benefit from the strips’ flexibility and customization. Artists incorporate them into sculptures, installations, and mixed-media works, using their glow to add depth and dimension. Sign makers use them to create custom signage for businesses, replacing traditional neon with a more durable, versatile alternative that can be shaped into any font, logo, or design. This allows for unique, eye-catching signage that stands out in busy commercial areas.

Neon Led Strip Lights offer distinct advantages over traditional neon and other lighting options, making them a superior choice for modern applications. Energy efficiency is a standout benefit, as they consume significantly less power than traditional neon tubes, reducing electricity costs and environmental impact. Their long lifespan—often 50,000 hours or more—minimizes replacement needs, further lowering maintenance expenses.

Durability sets them apart from fragile traditional neon. Unlike glass neon tubes, which shatter easily, Neon Led Strip Lights are encased in flexible, impact-resistant materials that withstand bumps, drops, and bending. This makes them suitable for high-traffic areas, children’s spaces, and outdoor environments where traditional neon would be impractical.

Versatility in design and installation surpasses both traditional neon and rigid LED strips. They can be shaped into virtually any form, installed in tight spaces, and adapted to both indoor and outdoor use, eliminating the need for multiple lighting products. Their ability to change colors (in RGB variants) adds another layer of versatility, allowing users to adjust lighting to match moods, seasons, or events.

Safety is enhanced by their low-voltage operation and minimal heat output. Unlike traditional neon, which operates at high voltages and generates significant heat, Neon Led Strip Lights are cool to the touch and pose a lower risk of electrical shock or fire, making them safer for homes, schools, and public spaces.

Maintaining Neon Led Strip Lights is simple, requiring minimal effort to keep them functioning optimally. Regular cleaning is essential to preserve light output, as dust, dirt, and fingerprints can accumulate on the casing and dull the glow. A soft, dry cloth or a slightly damp microfiber cloth is sufficient for wiping down the strip, taking care to avoid excessive pressure around connectors. For outdoor strips, a gentle rinse with a hose (on low pressure) can remove debris like leaves or pollen, followed by drying with a cloth. Harsh chemicals, abrasive cleaners, or scrub brushes should be avoided, as they can damage the casing or scratch the surface, impairing light diffusion.

Connection inspections help prevent performance issues. Over time, connectors between segments or to the power supply may loosen, especially in areas with vibration. Checking and securing these connections can prevent flickering, dimming, or sections of the strip failing. For outdoor installations, ensuring connectors are sealed with waterproof caps or silicone sealant is crucial to prevent moisture-related corrosion.

Damage checks are important, particularly in high-traffic areas. While the casing is durable, it can occasionally tear or puncture if exposed to sharp objects. Small tears can be repaired with silicone sealant, maintaining water resistance and protecting internal components. Severely damaged sections can be cut off at the nearest cut line and replaced, thanks to the strip’s modular design.

Power supply maintenance ensures consistent operation. The power adapter should be kept clean and dry, with the cord inspected for fraying. Using a manufacturer-recommended adapter (matching the strip’s voltage requirements) is critical, as incompatible adapters can damage the LEDs.

Neon Led Strip Lights are generally reliable, but occasional issues can be resolved with simple troubleshooting. Flickering or uneven lighting is often caused by loose connections or a faulty power supply. Securing connections or replacing the adapter typically fixes this. In longer strips, voltage drop may cause dimming at the far end; adding a second power supply midway ensures consistent brightness.

Color inconsistency in RGB strips may result from a malfunctioning controller or uneven LED wear. Resetting the controller, updating firmware (for smart models), or recalibrating colors can restore uniformity. Non-functional LEDs can be addressed by replacing the affected section, leveraging the strip’s modular design.

Adhesive failure may occur if the surface wasn’t properly prepared. Cleaning the surface with isopropyl alcohol to remove oils or dust, then reapplying the strip with firm pressure, improves adhesion. For rough surfaces, mounting clips or specialized tape offer secure alternatives.

Water damage in outdoor strips can cause corrosion or short circuits, often due to poorly sealed connectors or casing damage. Ensuring proper sealing and repairing casing damage with silicone sealant prevents further issues. Severely damaged sections may need replacement.

The evolution of Neon Led Strip Lights continues, with advancements enhancing functionality and versatility. Smart integration is a key trend, with strips increasingly featuring Bluetooth, Wi-Fi, or Zigbee connectivity. This allows control via apps, voice assistants, or home automation systems, enabling color changes, dimming, scheduling, and music synchronization. Future models may include AI-driven controls that learn user preferences, adjusting lighting automatically.

Energy efficiency is improving through advanced LED technology, with diodes producing more light while consuming less power. Sensors that adjust brightness based on ambient light optimize energy use, aligning with sustainable design trends.

Material advancements are enhancing durability, with next-generation silicones offering better UV and chemical resistance, extending outdoor lifespan. Stronger circuit boards may withstand more frequent bending, expanding installation possibilities.

Customization options are expanding, with manufacturers offering pre-cut shapes, custom colors, and printable casings for logos or patterns. 3D-printable mounting accessories allow tailored brackets or diffusers, further personalizing installations.

Neon Led Strip Lights have revolutionized lighting design, blending the timeless appeal of neon with the efficiency and versatility of LED technology. Their ability to adapt to any space—from intimate homes to grand commercial exteriors—while delivering vibrant, customizable illumination has made them indispensable in modern design.

As technology advances, their capabilities will grow, with smarter controls, improved materials, and enhanced customization ensuring they remain at the forefront of lighting innovation. Whether creating cozy ambiance, reinforcing brand identity, or inspiring artistic expression, Neon Led Strip Lights prove that lighting is not just functional—it’s a powerful tool for transforming spaces and enhancing experiences.