Time:2025-08-11

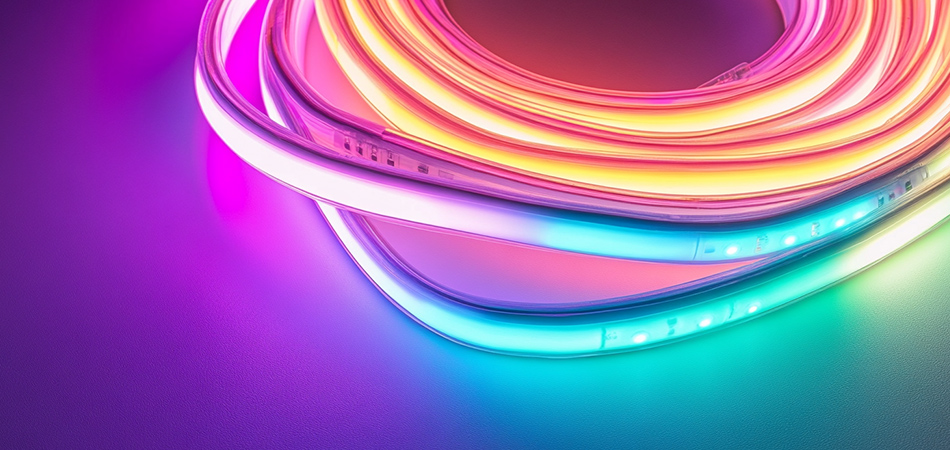

LED Silicone Neon Lights Strips represent a significant advancement in lighting technology, merging the classic aesthetic of traditional neon with the durability and efficiency of modern LEDs. Unlike glass neon tubes, which are fragile and energy-intensive, these strips use silicone casings to encase LED diodes, creating a flexible, robust alternative that retains the vibrant glow associated with neon. As industries and homeowners seek lighting solutions that balance visual appeal with practicality, LED Silicone Neon Lights Strips have emerged as a go-to choice. They offer the best of both worlds: the nostalgic charm of neon and the versatility to adapt to diverse environments, from indoor accent lighting to outdoor signage. This article explores their design features, material benefits, installation versatility, application ranges, and maintenance requirements, highlighting why they have become a staple in contemporary lighting design.

The effectiveness of LED Silicone Neon Lights Strips lies in their thoughtful design, which prioritizes both aesthetics and performance. Uniform light distribution is a key characteristic, achieved through precise placement of LED diodes within the silicone casing. This ensures that the light emitted is consistent along the entire length of the strip, avoiding the uneven "hot spots" or gaps that can plague lesser-quality lighting products. The silicone material acts as a natural diffuser, softening the light from individual LEDs to create a smooth, continuous glow that closely mimics the look of traditional glass neon.

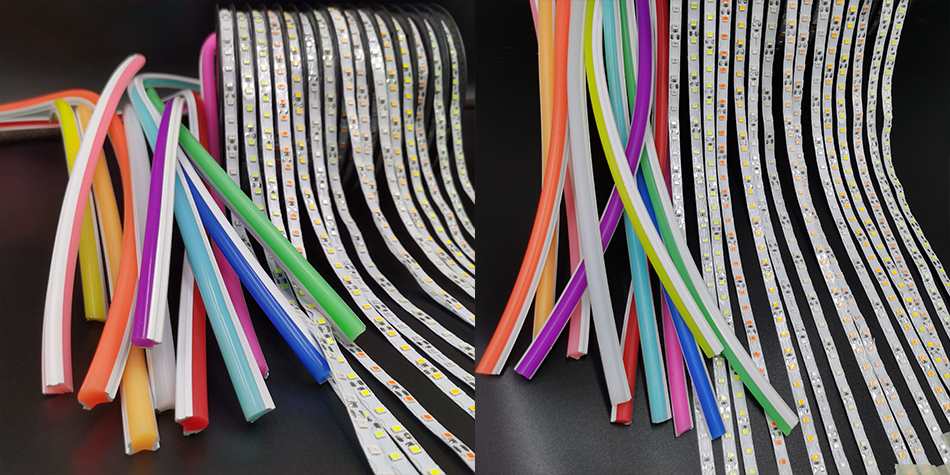

Flexibility is another defining feature, allowing the strips to be bent, curved, or wrapped around various surfaces. Unlike rigid glass neon, which requires specialized tools to shape, LED Silicone Neon Lights Strips can be manipulated by hand to fit corners, contours, or custom designs—whether outlining a curved headboard, wrapping around a staircase railing, or forming intricate shapes for signage. This flexibility opens up a wide range of creative possibilities, enabling designers to achieve forms that were previously difficult or impossible with traditional neon.

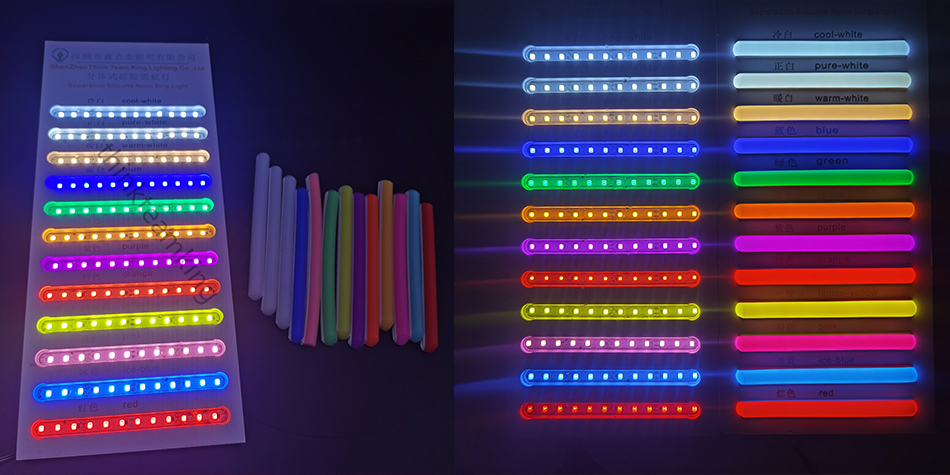

Color versatility caters to diverse design needs, with options ranging from single colors (such as warm white, cool white, red, or blue) to RGB (red-green-blue) variants that can produce millions of hues. RGB strips often come with remote controls or smart connectivity, allowing users to adjust colors dynamically, set patterns, or sync with music. This adaptability makes them suitable for environments where lighting needs to change with mood, season, or occasion—from a cozy home theater to a lively event venue.

Low-profile design ensures that the strips remain unobtrusive when installed. The silicone casing is slim yet sturdy, allowing the strips to blend into their surroundings without drawing attention to the fixture itself. This makes them ideal for applications where the focus should be on the light effect rather than the lighting device, such as under-cabinet lighting in kitchens or backlighting for artwork.

The use of silicone as the casing material is what sets these neon strips apart, offering a host of advantages over other materials like PVC or glass. Durability is a primary benefit, as silicone is highly resistant to impact, tearing, and extreme temperatures. Unlike glass neon, which shatters easily, or PVC strips that can crack in cold weather, LED Silicone Neon Lights Strips can withstand rough handling, making them suitable for high-traffic areas, children’s spaces, or outdoor environments.

Weather resistance extends their usability beyond indoor spaces. Silicone is inherently water-resistant, and many strips are rated for outdoor use, withstanding rain, snow, and humidity without degradation. This makes them ideal for outdoor applications such as patio lighting, garden accents, or exterior signage, where exposure to the elements would damage less robust lighting solutions. Additionally, silicone is UV-resistant, preventing the strips from fading or becoming brittle when exposed to direct sunlight over time.

Heat resistance ensures safe operation even during extended use. LEDs generate less heat than traditional neon, but the silicone casing further dissipates heat, preventing the strips from overheating or damaging nearby materials. This allows for installation close to fabrics, wood, or plastic surfaces without the risk of fire or warping, expanding their application potential in furniture, displays, or enclosed spaces.

Chemical resistance makes the strips easy to clean and maintain. Silicone is inert and resistant to most household cleaners, oils, and solvents, allowing for simple wipe-downs to remove dust, dirt, or stains. This is particularly useful in commercial settings like restaurants or retail stores, where cleanliness is a priority, or in outdoor areas where the strips may accumulate grime from the environment.

Installing LED Silicone Neon Lights Strips is designed to be straightforward, with options that cater to both DIY enthusiasts and professional installers. Adhesive backing is a common feature, allowing for quick and easy mounting on smooth surfaces such as walls, ceilings, glass, or metal. The adhesive is strong enough to hold the strips securely, even in vertical or overhead installations, while remaining removable in some cases for repositioning. For rough or uneven surfaces, mounting clips or brackets can be used to ensure a secure fit, preventing sagging or detachment over time.

Cuttable design adds to their flexibility, with pre-marked cut points along the strips that allow users to trim them to the exact length needed for a project. This eliminates waste and ensures a perfect fit, whether for a small accent light under a shelf or a long strip outlining the perimeter of a room. After cutting, the ends can be sealed with silicone caps (often included) to maintain water resistance, particularly important for outdoor or humid installations.

Connectable segments enable users to link multiple strips together, extending their length beyond what a single strip can provide. Connectors are typically included, allowing for tool-free assembly that simply clicks into place. This modular approach makes it easy to create custom lengths for large-scale projects, such as lighting a commercial sign or wrapping around a building’s facade, without the need for complex wiring.

Power options are varied to suit different applications. Most strips operate on low voltage (typically 12V or 24V), requiring a power adapter that plugs into a standard outlet. This makes them safe for use in homes, especially around children, as the low voltage reduces the risk of electrical shock. For larger installations or permanent setups, hardwired power supplies can be used, integrated into the building’s electrical system by a professional electrician for a seamless look.

LED Silicone Neon Lights Strips are versatile ezough to enhance a wide variety of spaces, both residential and commercial. Residential interiors benefit from their ability to add ambiance and highlight features. In living rooms, they can be installed behind TVs for bias lighting, reducing eye strain, or along the edges of bookshelves to showcase decor. Bedrooms use them as subtle nightlights, with strips under beds or behind headboards providing a soft glow that doesn’t disrupt sleep. Kitchens and bathrooms utilize their water resistance, with under-cabinet lighting or around mirrors adding functionality and style.

Commercial spaces leverage their durability and visual appeal for branding and customer engagement. Retail stores use them to highlight product displays, create eye-catching window fronts, or outline store logos, attracting passersby and guiding customers through the space. Restaurants and bars employ them to set moods—warm white strips for a cozy atmosphere, or colorful RGB strips for a lively vibe—installed under counters, along banquettes, or behind bars. Offices and coworking spaces use them to add energy and define zones, with strips along desk edges or meeting room perimeters.

Outdoor environments showcase their weather resistance, with applications ranging from residential patios to public spaces. Homeowners use them to illuminate walkways, outline patio furniture, or highlight garden features, creating an inviting outdoor living area. Commercial properties like hotels or resorts install them along building exteriors, pool decks, or outdoor dining areas to extend their brand aesthetic into outdoor spaces. Event planners use them for temporary setups, such as wedding backdrops or festival stages, thanks to their portability and easy installation.

Art and signage benefit from their flexibility and customizability. Artists incorporate LED Silicone Neon Lights Strips into sculptures, installations, or mixed-media art, using their glow to add depth and dimension. Sign makers use them to create custom signage for businesses, replacing traditional glass neon with a more durable, cost-effective alternative that can be shaped into any font or logo.

LED Silicone Neon Lights Strips offer distinct benefits compared to traditional glass neon and even other types of LED strips, making them a superior choice in many scenarios. Energy efficiency is a standout advantage, as they consume significantly less power than traditional neon tubes—up to 80% less—resulting in lower electricity bills and reduced environmental impact. They also have a much longer lifespan, often lasting 50,000 hours or more, compared to the 10,000–20,000 hours of glass neon, reducing the need for frequent replacements.

Safety is another key benefit. Unlike glass neon, which operates at high voltages and can shatter into sharp pieces, LED Silicone Neon Lights Strips use low voltage and are encased in shatterproof silicone, making them safer for use in homes, schools, or public spaces. They also generate less heat, reducing the risk of burns or fire hazards when touched or installed near flammable materials.

Cost-effectiveness becomes apparent over time, despite a potentially higher initial investment than some basic LED strips. Their long lifespan, energy efficiency, and low maintenance requirements mean they cost less to operate and replace over their lifetime. Additionally, their durability reduces the need for frequent repairs, which can be costly with traditional neon, especially in hard-to-reach locations.

Versatility surpasses both traditional neon and PVC LED strips. While glass neon is limited by its fragility and rigidity, and PVC strips may lack flexibility or weather resistance, silicone neon strips combine the best of all worlds: flexibility, durability, and adaptability to both indoor and outdoor use. This versatility makes them a one-stop solution for a wide range of lighting needs, eliminating the need for multiple types of lighting products.

Maintaining LED Silicone Neon Lights Strips is simple, requiring minimal effort to keep them functioning and looking their best. Regular cleaning is the primary maintenance task, with a soft, dry cloth or a slightly damp cloth used to wipe down the silicone casing. This removes dust, dirt, or fingerprints that can dull the light output. For outdoor strips, a gentle rinse with a hose (on low pressure) can help remove accumulated debris like leaves or pollen, followed by drying with a cloth. Harsh chemicals or abrasive cleaners should be avoided, as they can damage the silicone or the LED diodes inside.

Connection checks help prevent performance issues. Over time, connectors between strips or to the power supply may loosen, especially in areas with vibration or movement. Periodically inspecting and tightening these connections ensures consistent power flow, preventing flickering or sections of the strip from failing. For outdoor installations, checking that connectors are properly sealed with silicone caps or tape prevents moisture from entering and causing corrosion.

Inspection for damage is important, especially after installation or in high-traffic areas. While the silicone casing is durable, it can occasionally tear or puncture if subjected to sharp objects or excessive force. Small tears can be repaired with silicone sealant, which maintains water resistance and protects the internal components. If a section of the strip is severely damaged, it can be cut off at the nearest cut point and replaced, thanks to the modular design.

Power supply maintenance ensures consistent operation. The power adapter should be kept clean and dry, with the cord inspected for fraying or damage. If the adapter fails, replacing it with a manufacturer-recommended model (matching the strip’s voltage requirements) is crucial, as using an incompatible adapter can damage the LEDs.

While LED Silicone Neon Lights Strips are generally reliable, users may encounter occasional challenges that can be easily addressed. Flickering or uneven lighting is often caused by loose connections or a faulty power supply. Checking and securing all connections, or replacing the power adapter, typically resolves this issue. In longer strips, voltage drop can cause dimming at the far end; adding a second power supply midway through the strip ensures consistent brightness.

Color inconsistency in RGB strips may occur due to poor synchronization or a malfunctioning controller. Resetting the controller, updating its firmware (for smart models), or recalibrating the colors can restore uniformity. If individual LEDs fail, the affected section can be cut off and replaced, as the modular design allows for easy repairs.

Adhesive failure can happen if the surface wasn’t properly prepared before installation. Cleaning the surface with isopropyl alcohol to remove oils or dust, then reapplying the strip with firm pressure, improves adhesion. For surfaces where adhesive doesn’t work well, using mounting clips or double-sided tape designed for rough surfaces provides a secure alternative.

Outdoor durability issues may arise in extreme conditions, such as prolonged exposure to freezing temperatures or heavy rain. Choosing strips with a high IP rating (IP65 or higher) ensures better water and dust resistance. Additionally, securing outdoor strips with weatherproof mounting hardware and protecting connections with silicone sealant enhances their ability to withstand harsh environments.

The development of LED Silicone Neon Lights Strips continues to advance, with new features and improvements enhancing their functionality and appeal. Smart integration is a growing trend, with more strips incorporating Bluetooth or Wi-Fi connectivity that allows control via smartphones, voice assistants, or home automation systems. This enables users to adjust colors, brightness, and patterns remotely, set schedules, or sync with other smart devices, adding convenience and customization.

Enhanced energy efficiency is being achieved through advancements in LED technology, with newer diodes consuming even less power while producing brighter light. This reduces energy costs further and extends the strips’ lifespan, making them an even more sustainable choice. Some models also include sensors that automatically adjust brightness based on ambient light, optimizing energy use.

Customization options are expanding, with manufacturers offering more shapes, sizes, and color options to meet specific design needs. Custom-cut strips to exact measurements, or pre-shaped designs for signage or art projects, are becoming more readily available, reducing the need for users to modify the strips themselves. Additionally, printable silicone casings allow for custom patterns or logos to be applied directly to the strips, opening up new branding possibilities.

Eco-friendly materials are gaining traction, with manufacturers developing silicone casings made from recycled materials or biodegradable alternatives. This reduces the environmental impact of the strips, aligning with growing consumer demand for sustainable products. Additionally, lead-free solder and RoHS-compliant components ensure that the strips are safe for both users and the environment.

LED Silicone Neon Lights Strips have revolutionized the lighting industry, offering a perfect blend of aesthetic appeal, durability, and versatility. Their ability to mimic the look of traditional neon while addressing its shortcomings—fragility, high energy use, and maintenance needs—has made them a favorite among homeowners, designers, and businesses alike. Whether used to add ambiance to a home, attract customers to a store, or create stunning outdoor displays, these strips deliver consistent, reliable performance in a wide range of environments.

As technology continues to advance, their capabilities will only grow, with smarter features, greater customization, and more sustainable materials on the horizon. For anyone seeking a lighting solution that combines style, durability, and practicality, LED Silicone Neon Lights Strips stand out as a superior choice, proving that innovation in lighting can preserve the best of the past while embracing the efficiency of the future.