Time:2025-07-17

The Critical Role of Hygienic Signage in Commercial Kitchens

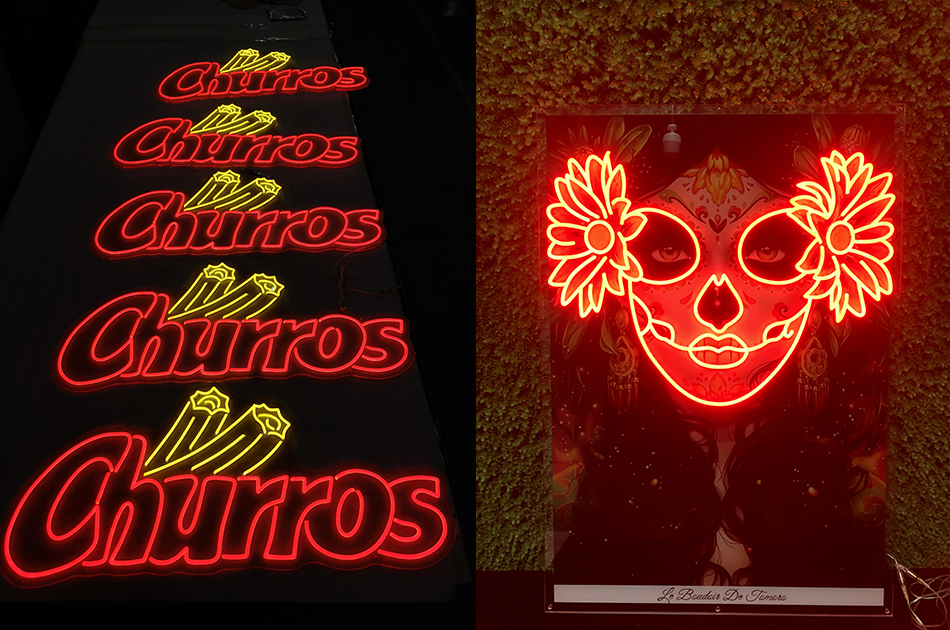

In the high-stakes environment of commercial kitchens, where cleanliness and efficiency are paramount, hygienic washable neon signs have emerged as essential tools for maintaining safety, streamlining workflows, and ensuring compliance with food safety regulations. These specialized signs combine the vibrant visibility of neon lighting with materials and designs engineered to withstand frequent cleaning, high humidity, and exposure to food residues. From busy restaurant kitchens to institutional cafeterias, they provide clear, durable signage for zones like prep areas, storage units, and allergen stations—all while resisting bacteria growth and chemical corrosion. This article explores the technical innovations, design principles, and practical applications of these signs, offering a comprehensive guide for foodservice operators, kitchen designers, and safety officers.

Technical Foundations: Engineering for Cleanability and Durability

Core Materials for Hygienic Performance

Food-Grade Silicone Encapsulation

Primary Barrier Against Contamination: LED neon flex in kitchen signs is encased in medical-grade silicone (FDA-compliant) with a smooth, non-porous surface. This material repels water, oil, and food particles, preventing buildup in crevices and eliminating hiding spots for bacteria. Its flexibility allows for curved designs (e.g., around prep tables) without compromising structural integrity.

Heat and Chemical Resistance: Silicone casings withstand temperatures up to 200°C (392°F), making them safe near stovetops and ovens. They resist degradation from common kitchen cleaners (e.g., sanitizing sprays, degreasers, and bleach solutions), ensuring longevity even with daily washing.

Stainless Steel Structural Components

Frames and Backings: Sign frames and mounting hardware use 304 or 316 grade stainless steel, chosen for their resistance to rust, corrosion, and pitting from moisture and food acids. These metals are non-reactive, preventing chemical leaching and meeting strict food contact standards.

Seamless Construction: Welded or laser-cut joints eliminate gaps where debris could accumulate, creating a smooth surface that’s easy to wipe down. Rounded edges and corners further reduce areas prone to dirt buildup.

Waterproof Electrical Systems

Sealed Power Connections: Electrical components (LED drivers, connectors) are encased in IP66/IP67-rated enclosures, protecting against water ingress during cleaning or accidental spills. Low-voltage operation (12V/24V DC) minimizes electrical hazards in wet environments.

Detachable Wiring: Quick-disconnect plugs allow safe removal of sign panels during deep cleaning, enabling thorough sanitization of both the sign and its mounting surface without damaging electrical components.

Design Principles for Hygienic Washable Neon Signs

Cleanability as a Core Design Criterion

Seamless and Smooth Surfaces:

No Grooves or Indentations: Sign faces and edges are designed with continuous, flat surfaces to prevent food particles from lodging in crevices. Even lettering uses rounded edges and minimal depth, ensuring cleaning cloths or spray nozzles can reach all areas.

Non-Stick Coatings: Optional food-grade Teflon or silicone coatings on stainless steel frames reduce adhesion of grease and grime, allowing for faster, more effective cleaning.

Ergonomic Placement for Accessibility:

Height and Angle Optimization: Signs are mounted at waist to eye level, avoiding hard-to-reach areas above equipment or below counters. Angled surfaces (5–15° from vertical) encourage runoff of cleaning fluids, preventing pooling.

Clearance from Heat Sources: Positioned at least 30cm away from open flames, grills, or fryers to avoid silicone degradation and reduce fire risks, while remaining visible to kitchen staff.

Visibility and Functionality in Busy Kitchens

High-Contrast Color Schemes:

Bright Hues on Dark Backings: Neon colors like red (for “DANGER” or “ALLERGEN ZONE”), green (for “SAFE”), or white (for general instructions) are paired with matte black or stainless steel backings. This contrast ensures readability even through steam, grease, or low lighting.

Anti-Glare Properties: Matte silicone casings reduce reflection from overhead lights or stove hoods, maintaining visibility in glare-prone areas like dishwashing stations.

Simplified Typography and Icons:

Bold, Sans-Serif Fonts: Letters with thick strokes (e.g., Impact, Arial Black) resist smudging and remain legible after repeated cleaning. Short, action-oriented phrases (“WASH HANDS,” “COOK TO 165°F”) work best.

Universal Symbols: Pictograms (e.g., a fork and knife for “SERVING AREA,” a droplet for “WASH STATION”) complement text, aiding comprehension for multilingual staff and reducing reliance on detailed wording.

Strategic Applications in Kitchen Environments

Zoning and Workflow Management

Prep and Cooking Areas:

Allergen Zoning: Neon signs labeling “NUT-FREE PREP” or “GLUTEN AREA” in bright red, with washable surfaces that withstand hourly sanitization. These signs are critical for preventing cross-contamination in restaurants with strict allergen protocols.

Cooking Station Identification: “GRILL,” “FRYER,” or “OVEN” signs in heat-resistant silicone, mounted above respective equipment to guide staff in fast-paced environments.

Storage and Inventory Zones:

Temperature-Controlled Areas: Neon signs for “REFRIGERATED” (blue) or “DRY STORAGE” (green) with waterproof casings, easily cleaned during weekly inventory checks. Their visibility reduces errors in stock placement.

Safety and Compliance Signage

Hazard Communication:

Slip and Trip Warnings: “WET FLOOR” signs with flashing neon edges (battery-powered for portability) that can be wiped down after spills, ensuring compliance with OSHA standards.

Emergency Exits: Illuminated “EXIT” signs in green neon, mounted near kitchen doors with washable frames, ensuring visibility even during power outages (when paired with battery backups).

Hygiene Protocols:

Hand Washing Reminders: Neon signs above sinks reading “WASH HANDS FOR 20 SECONDS” in white, with smooth surfaces that tolerate frequent spray cleaning. These reinforce critical food safety habits.

Temporary and Flexible Signage

Mobile Prep Stations:

Magnetic Mounts: Washable neon signs with magnetic backings, easily moved between temporary prep tables during catering events or busy service periods. They resist food splatters and can be sanitized between uses.

Event-Specific Zones: For pop-up kitchens or food festivals, lightweight washable signs labeling “VEGETARIAN” or “SPICY” stations, quickly cleaned between service shifts.

Installation and Maintenance Best Practices

Professional Installation for Safety Compliance

Electrical Safety:

Certified Wiring: All electrical connections must meet NFPA 70 (National Electrical Code) standards for wet locations, with ground-fault circuit interrupters (GFCIs) to prevent shocks.

Heat Resistance Testing: Signs near high-temperature equipment undergo thermal testing to ensure silicone casings remain stable, with professional installers verifying safe distances from heat sources.

Mounting Security:

Stainless Steel Brackets: Heavy-duty mounts with tamper-resistant screws secure signs to walls or equipment, preventing accidental dislodging during cleaning or collisions with carts.

Sealed Edges: Installers apply food-grade silicone sealant around mounting points to prevent moisture ingress behind the sign, a common breeding ground for mold.

Routine Cleaning and Maintenance

Daily Sanitization:

Spray and Wipe: Use a solution of mild detergent and water, applied with a microfiber cloth or spray bottle. Avoid abrasive pads that could scratch silicone or stainless steel surfaces.

High-Pressure Tolerance: For heavily soiled areas (e.g., near fryers), signs with IP66 ratings can withstand low-pressure hose washing (up to 10 bar), simplifying deep cleaning.

Periodic Inspections:

Monthly Seal Checks: Examine silicone casings and electrical enclosures for cracks or loosening, replacing damaged components to maintain waterproofing and hygiene.

LED Functionality Tests: Verify all neon segments light uniformly, replacing dim or flickering LEDs to ensure visibility—critical for safety signs.

Selecting the Right Hygienic Neon Sign Provider

Compliance with Food Safety Standards

Material Certifications: Ensure silicone casings and stainless steel components carry FDA, LFGB, or NSF certifications, confirming they’re safe for use in food preparation areas and resistant to food-grade chemicals.

Third-Party Testing: Look for providers with test reports verifying washability (e.g., 500+ cleaning cycles without degradation) and heat resistance (up to 200°C) for kitchen-specific durability.

Design and Customization Capabilities

Kitchen-Specific Templates: Providers offering pre-designed templates for common kitchen zones (“PREP,” “SAFE,” “ALLERGEN”) reduce lead times, while custom options for unique workflows (e.g., “VEGAN ONLY”) ensure alignment with operational needs.

Ergonomic Expertise: Choose suppliers with experience in commercial kitchen design, able to recommend optimal sizing, placement, and color schemes based on workflow analysis.

Durability and Warranty

Lifespan Guarantees: Seek signs with 3–5 year warranties covering silicone degradation, LED failure, and structural rust, with clear terms for replacement or repair.

After-Sales Support: Providers offering on-site maintenance or quick replacement of washable components (e.g., silicone casings) minimize downtime in busy kitchens.

Innovations in Hygienic Neon Sign Technology

Advanced Material Science

Antimicrobial Silicone: Emerging formulations infused with silver ions or zinc compounds that inhibit bacterial growth (e.g., E. coli, Salmonella) on sign surfaces, reducing reliance on frequent cleaning.

Self-Cleaning Coatings: Photocatalytic layers that break down organic residues when exposed to light, complementing manual cleaning and maintaining hygiene between shifts.

Smart Hygiene Integration

Cleaning Reminder Sensors: Embedded sensors that detect when a sign hasn’t been cleaned for a set period (e.g., 4 hours), triggering a subtle flash to alert staff—ideal for high-risk areas like allergen prep zones.

Wireless Monitoring: Bluetooth-enabled signs that log cleaning cycles and send alerts to management devices, ensuring compliance with HACCP or FDA inspection requirements.

Energy Efficiency for 24/7 Operation

Motion-Activated Lighting: Sensors that dim neon signs when no staff are present (e.g., overnight) and brighten when motion is detected, reducing energy use without compromising visibility during active hours.

Overcoming Kitchen-Specific Challenges

Challenge 1: Grease Buildup on Sign Surfaces

Solution: Use ultra-smooth silicone with low surface tension, causing grease to bead and wipe away easily. Pair with degreaser-compatible materials to maintain integrity during deep cleans.

Challenge 2: Steam and Condensation Damage

Solution: Opt for IP67-rated enclosures and hermetically sealed LED modules to prevent moisture ingress, with sloped sign tops that channel condensation away from electrical components.

Challenge 3: Heat-Related Degradation

Solution: Select high-temperature silicone (rated for 200°C+) and position signs at least 30cm from heat sources, with thermal insulation between the sign and mounting surface in extreme cases.

Conclusion: Hygienic Neon Signs as a Pillar of Kitchen Safety

Hygienic washable neon signs are more than just functional tools—they are integral to maintaining food safety, streamlining workflows, and ensuring compliance in commercial kitchens. By combining durable, easy-to-clean materials with high-visibility design, these signs address the unique challenges of kitchen environments, from grease and steam to the need for constant sanitization.

As foodservice regulations grow stricter and consumer expectations for safety rise, investing in hygienic neon signage becomes a proactive step toward operational excellence. For kitchen operators, these signs offer peace of mind, knowing that critical information remains visible, clean, and effective—even in the busiest, messiest environments. In the end, they prove that visibility and hygiene can coexist, creating safer, more efficient kitchens where every detail matters.