Time:2025-07-11

The Evolution of Flexible Neon Strips in Modern Lighting

In an era where design demands both creativity and functionality, flexible neon strips have emerged as a revolutionary lighting solution, merging the timeless allure of traditional neon with the technical advancements of modern LED technology. These versatile systems transcend conventional lighting limitations, offering seamless adaptability to diverse architectural landscapes, energy efficiency, and durable performance. From residential sanctuaries to large-scale commercial complexes, flexible neon strips are transforming how spaces are illuminated, experienced, and remembered.

This comprehensive guide explores the technical foundations, design possibilities, and practical applications of flexible neon strips, providing insights for designers, installers, and enthusiasts seeking to leverage their potential in creating dynamic, bespoke lighting environments.

Technical Foundations: The Anatomy of Flexible Neon Strips

Core Components for Flexibility and Performance

Flexible Substrate Technology

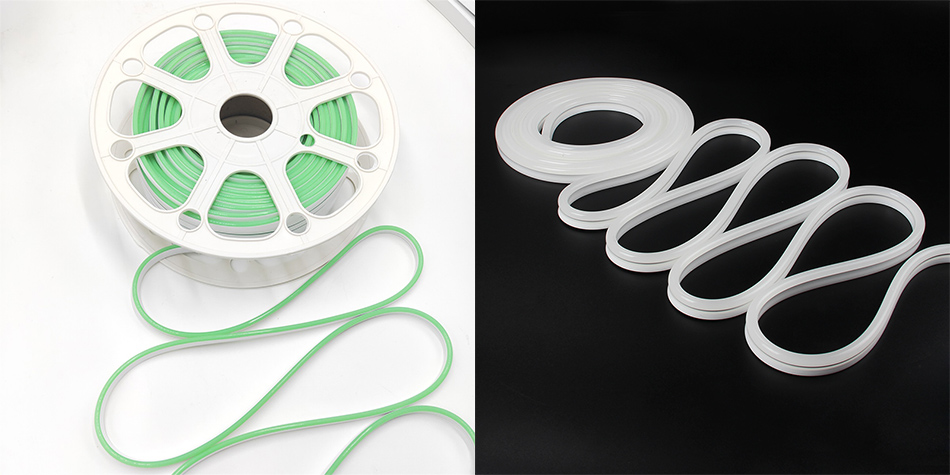

At the heart of these strips lies a flexible printed circuit board (PCB), typically constructed from polyimide or fiberglass-reinforced materials. This substrate enables the strip to bend, twist, and conform to radii as tight as 15–30mm, adapting to curved surfaces, angular edges, or irregular structures without compromising electrical integrity. The PCB serves as a stable base for mounting LED chips, ensuring uniform current distribution and minimizing voltage drop across long lengths.

Encapsulation Materials for Protection and Aesthetics

Silicone Encasing: Renowned for its durability and elasticity, silicone offers superior resistance to UV radiation, temperature extremes (-50°C to 150°C), and mechanical stress. Ideal for outdoor applications, it provides a smooth, diffused light output while safeguarding against moisture, dust, and physical impacts.

PVC Sheathing: A cost-effective alternative for indoor use, PVC casings offer moderate flexibility and fire-retardant properties (UL 94-V0 rating), making them suitable for commercial spaces and residential interiors.

LED Technology for Efficient Illumination

High-Efficiency LEDs: Surface-mounted diodes deliver intense, consistent brightness while consuming minimal power. Advanced packaging techniques ensure tight color tolerances, enabling precise reproduction of brand colors or custom palettes.

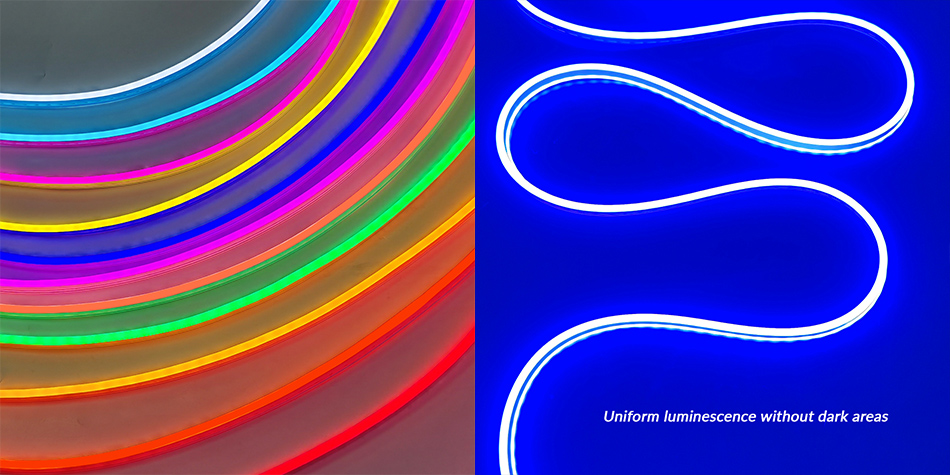

Optical Diffusion: Translucent encapsulation materials scatter light evenly, eliminating hotspots and creating a soft, ambient glow—perfect for architectural accent lighting or decorative applications.

Core Advantages: Why Flexible Neon Strips Stand Out

Unrestricted Design Freedom

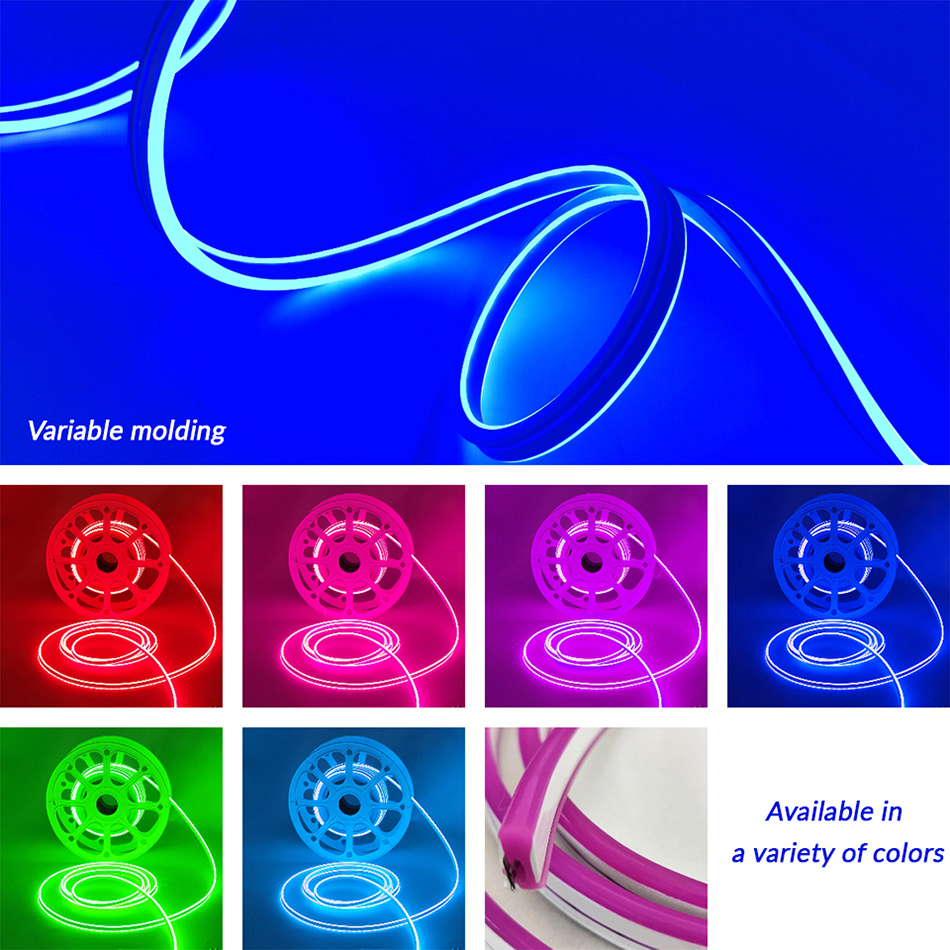

Contour Conformity: Seamlessly wrap around columns, arches, furniture, or signage, transforming static structures into illuminated focal points. Their ability to follow complex geometries makes them ideal for modern minimalist designs or ornate traditional spaces.

Modular Customization: Pre-marked cut points allow easy trimming to exact lengths, while universal connectors enable seamless 拼接 of multiple segments. This modularity supports everything from small-scale DIY projects to large-scale commercial installations.

Durability for Diverse Environments

Weather Resistance: IP65/IP67-rated variants withstand rain, snow, and UV exposure, making them suitable for outdoor facades, pool areas, or coastal installations. Indoor strips meet strict fire safety standards, ensuring compliance in public spaces.

Vibration and Impact Resistance: Reinforced PCBs and shock-absorbent mounts protect against mechanical stress in high-traffic zones, such as retail aisles, hospitality venues, or transportation hubs.

Energy Efficiency and Longevity

Low-Voltage Operation: Running on 12V/24V DC, these strips consume up to 80% less energy than traditional neon or halogen lighting, reducing operational costs and environmental impact.

Extended Lifespan: With a lifespan exceeding 50,000 hours, LED-based flexible neon strips minimize replacement frequency, offering long-term reliability for both temporary and permanent installations.

Ease of Installation and Integration

Tool-Free Setup: Adhesive backing, magnetic mounts, or clip systems enable quick installation on glass, metal, wood, or fabric surfaces, reducing labor time and complexity.

Smart System Compatibility: Built-in drivers support integration with DMX512, Bluetooth, or Wi-Fi controllers, allowing remote adjustment of color, brightness, and dynamic effects—perfect for smart homes, commercial automation, or event venues.

Applications Across Industries and Spaces

Residential: Personalized Ambiance with Professional Finish

Interior Design

Architectural Accents: Highlight crown moldings, tray ceilings, or staircase balustrades with subtle neon strips, adding depth and warmth to living spaces.

Functional Lighting: Under-cabinet illumination in kitchens, backlighting for bathroom mirrors, or shelf-edge lighting in home offices—tailored to fit unique layouts with precision.

Bedroom Retreats: Soft, dimmable neon strips along headboards or wardrobe edges create a cozy, modern ambiance, adjustable via smart controls for personalized mood settings.

Outdoor Living

Garden Landscaping: Outline pathways, tree trunks, or water features with weatherproof strips, enhancing safety and aesthetics. Solar-powered variants offer eco-friendly solutions for remote or off-grid areas.

Patio and Deck Decor: Wrap neon around pergola beams or railing posts, creating inviting outdoor spaces for evening gatherings with customizable color schemes.

Commercial: Branding and Experience Enhancement

Retail and Signage

Storefront Identity: Custom-shaped neon logos on facades or window displays, ensuring 24/7 brand visibility with weather-resistant designs. Dynamic color changes can highlight promotions or seasonal themes.

In-Store Navigation: Colored strips as aisle markers or product zone indicators (e.g., red for sales areas, blue for electronics), guiding customers and enhancing shopping experiences.

Hospitality and Events

Restaurant Ambiance: Line bar counters, booths, or menu boards with dimmable neon, adapting from vibrant lunchtime hues to intimate evening tones. Waterproof strips in outdoor dining areas withstand unpredictable weather.

Hotel Luxury: Illuminated architectural features in lobbies, guest rooms, or spas, with RGBW variants enabling seamless color transitions to match the hotel’s brand aesthetic or guest preferences.

Corporate Offices

Reception Areas: Backlit company logos or art installations with uniform neon backlighting, creating professional first impressions.

Open Office Zoning: Colored strips to demarcate work zones (e.g., green for collaborative areas, amber for focus zones), enhancing spatial organization in modern workplaces.

Industrial and Functional Settings

Warehouse and Logistics

Safety and Navigation: High-visibility strips along rack edges, aisles, or emergency exits, improving worker safety and inventory management. Durable variants withstand dust, vibrations, and temperature fluctuations.

Equipment Illumination: Flexible neon on machinery or control panels, indicating operational status or highlighting maintenance points with color-coded signals.

Transportation

Vehicle Interiors: Custom-fit strips in cars, RVs, or aircraft cabins, adhering to curved surfaces for ambient lighting or task illumination. Low heat emission ensures safety in confined spaces.

Transit Hubs: Illuminated wayfinding in airports or train stations, with weatherproof strips guiding passengers through terminals or parking structures.

Outdoor Advertising and Architecture

Billboards and Facades: Dynamic neon outlines on building exteriors or advertising structures, programmable for the effects that comply with local signage regulations.

Public Art Installations: Flexible neon as a medium for large-scale light sculptures or interactive displays, adapting to complex artistic visions with ease.

Design and Installation Best Practices

Phase 1: Conceptualization and Site Analysis

Environmental Assessment:

Indoor: Evaluate fire codes, surface materials, and ambient light levels to select appropriate strip types (e.g., fire-retardant PVC for offices, silicone for kitchens).

Outdoor: Assess weather exposure, UV intensity, and mechanical stress to specify IP ratings (IP67 for coastal areas, IP65 for urban environments) and material thickness.

Design Intent Mapping:

Collaborate with architects/designers to identify focal points, color palettes, and lighting moods. Use 3D modeling to visualize strip placement on complex surfaces.

Phase 2: Material Selection and Customization

Substrate and Encapsulation Choices:

Flexibility Needs: Opt for silicone strips (bend radius <20mm) for tight curves; PVC for straight runs in low-movement areas.

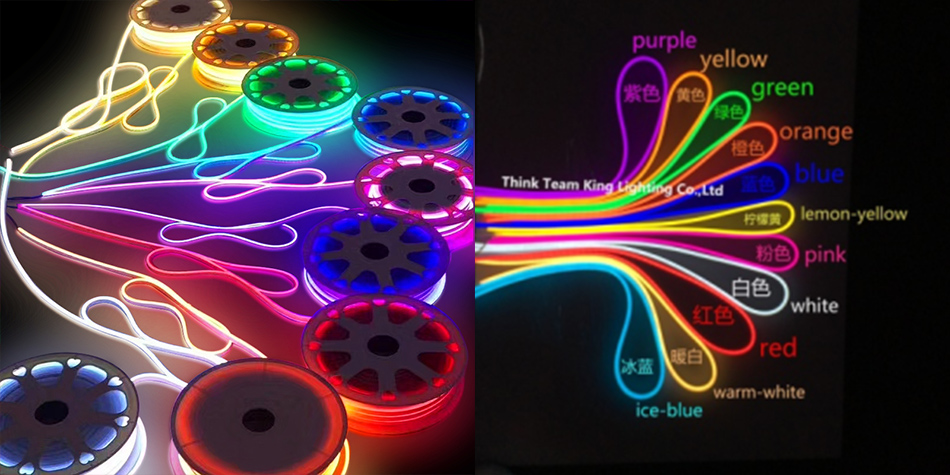

Color and Light Quality: Select RGB for dynamic effects, single-color for brand consistency, or RGBW for warm/cool white adjustments.

Power and Control Systems:

Low-Voltage Solutions: Use battery packs, solar panels, or centralized power supplies based on installation scale and mobility needs.

Smart Integration: Choose strips compatible with existing control systems (e.g., Crestron, Lutron) for seamless automation.

Phase 3: Installation Techniques

Mounting Methods:

Adhesive Application: Clean surfaces thoroughly and apply pressure evenly to ensure adhesive bonds, ideal for smooth materials like glass or acrylic.

Mechanical Fixings: Use clips, brackets, or magnetic mounts for textured surfaces or heavy strips, spacing supports every 15–30cm for stability.

Electrical Integration:

Conceal wiring within channels or behind structures to maintain a clean aesthetic. Use polarity-protected connectors to avoid installation errors.

Phase 4: Testing and Maintenance

Functional Testing:

Verify uniform illumination, color accuracy, and control responsiveness. Address any dark spots or connector issues before finalizing the installation.

Routine Care:

Indoor: Dust gently with a soft cloth; avoid abrasive cleaners that may damage the casing.

Outdoor: Inspect seals and connectors quarterly, replacing worn components to maintain weatherproofing.

Key Considerations When Selecting Flexible Neon Strips

Environmental Compatibility

Temperature Range: Ensure the strip’s operational limits match the installation environment (e.g., -40°C to 80°C for industrial freezers or machinery rooms).

Chemical Resistance: Silicone is ideal for areas exposed to cleaning agents or oils; PVC suffices in dry, low-contamination spaces.

Lighting Performance

Brightness Levels: Higher LED density (e.g., 60 LEDs/m) for high-visibility applications; lower density (30 LEDs/m) for ambient or backlighting.

Color Rendering Index (CRI): Prioritize CRI >90 for retail or hospitality settings where accurate color representation is critical (e.g., fashion boutiques, art galleries).

Certification and Compliance

Safety Standards: Look for UL 1838 (outdoor signage), CE EN 60598 (indoor lighting), and RoHS compliance for eco-friendly materials.

Fire Ratings: UL 94-V0 rated strips for indoor commercial use to meet strict fire codes.

Supplier Expertise

Portfolio Review: Choose suppliers with experience in similar projects (e.g., retail chains, residential complexes) and a track record of color matching and custom bending.

Technical Support: Suppliers offering installation guides, troubleshooting assistance, and warranty coverage (typically 2–5 years) ensure long-term satisfaction.

Innovations Shaping the Future of Flexible Neon Strips

Smart and Sustainable Technologies

IoT Integration: Bluetooth/Wi-Fi-enabled strips allow real-time control via mobile apps, with features like motion-activated dimming or voice commands (compatible with Alexa, Google Assistant).

Energy Harvesting: Solar-powered and kinetic energy-driven strips reduce reliance on grid power, ideal for remote or eco-conscious installations.

Advanced Materials and Design

Graphene-Enhanced Flex: Emerging substrates offer improved thermal conductivity and bend resilience, enabling thinner, more durable strips for minimalist designs.

Transparent Neon: Invisible connectors and clear casings create the illusion of floating light, perfect for glass installations or seamless architectural integration.

Customization and Manufacturing

3D-Printed Accessories: Tailored mounting solutions and connectors created via 3D printing, adapting to unique project geometries with precision.

AI-Design Tools: Software that generates optimal strip layouts based on space parameters, ensuring uniform illumination and minimal material waste.

Overcoming Common Challenges

Challenge 1: Inconsistent Light Output

Solution: Source strips from the same production batch and use professional color calibration tools to ensure uniformity across segments.

Challenge 2: Adhesive Failure on Textured Surfaces

Solution: Combine adhesive with mechanical mounts (e.g., clips or Velcro) for rough surfaces, ensuring both security and easy removal.

Challenge 3: Complex Curves and Angles

Solution: Use bending templates or partner with suppliers for pre-formed strips, ensuring precise conformity to architectural features.

Challenge 4: Outdoor Degradation

Solution: Select UV-stabilized silicone strips and apply protective coatings to connectors, paired with annual inspections to address wear early.

Conclusion: The Endless Potential of Flexible Neon Strips

Flexible neon strips have transcended traditional lighting to become a cornerstone of modern design, offering a rare blend of adaptability, durability, and aesthetic appeal. From enhancing residential comfort to defining commercial brand identities, these systems empower creators to transform spaces with unprecedented precision and creativity. As technology continues to advance—bringing smarter controls, sustainable materials, and innovative manufacturing—flexible neon strips will only grow more indispensable, proving that light itself can be as dynamic, resilient, and visionary as the spaces it illuminates.

By prioritizing quality, compliance, and thoughtful design, professionals and enthusiasts alike can harness the full potential of flexible neon strips, creating environments that not only light up spaces but also leave a lasting impression. In a world where design and functionality are increasingly intertwined, these strips stand as a testament to what’s possible when technology meets imagination.