Time:2025-07-11

The Critical Need for Industrial-Grade Lighting in Warehouses

In the fast-paced world of logistics and industrial operations, industrial flexible neon strips have emerged as a transformative solution for warehouse lighting, addressing the unique challenges of large-scale storage environments. Warehouses demand lighting systems that combine durability, adaptability, and functional illumination to support inventory management, worker safety, and operational efficiency. Industrial flexible neon strips, engineered to withstand harsh conditions while offering customizable lighting solutions, are revolutionizing how warehouses approach visibility and safety, proving indispensable in modern supply chain facilities.

This article explores the technical innovations, operational advantages, and strategic applications of industrial flexible neon strips in warehouses, providing a comprehensive guide for optimizing storage environments through robust and adaptable lighting design.

Technical Foundations: Engineered for Industrial Rigor

Durability-Driven Design for Warehouse Environments

Warehouses expose lighting systems to extreme conditions, and industrial flexible neon strips are built to endure:

Heavy-Duty Encapsulation

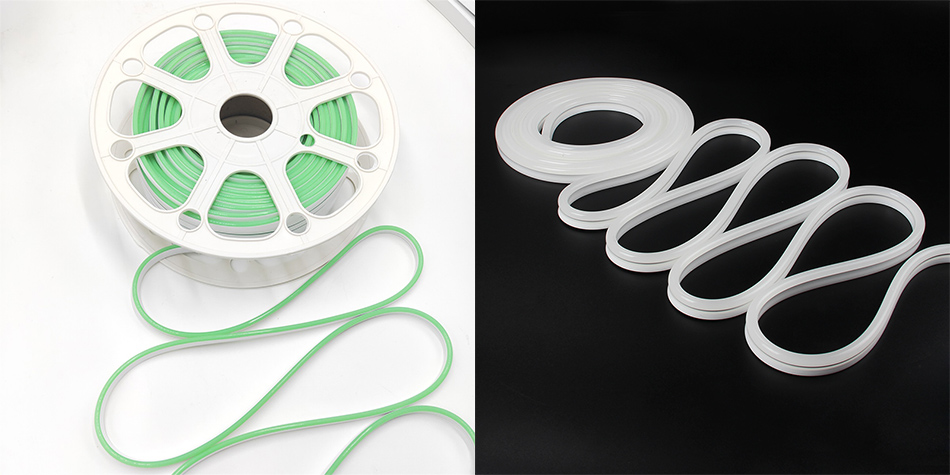

Industrial-Grade Materials: Outer casings made from reinforced silicone or polycarbonate, capable of withstanding impacts, dust, and chemical exposure. Silicone variants offer superior resistance to oils, solvents, and temperature fluctuations (-40°C to 70°C), while polycarbonate provides rigidity in high-vibration zones near machinery.

IP67/IP69K Ratings: Fully sealed connectors and seamless encapsulation protect against dust ingress and high-pressure water jets, essential for washdown areas or outdoor loading docks.

Vibration and Impact Resistance

Reinforced PCB Substrates: Flexible PCBs embedded with metal cores or fiberglass layers, tested to withstand 5G vibration levels common in warehouses with forklifts, conveyor belts, or automated storage systems.

Shock-Absorbent Mounting: Specialized clips and brackets that dampen mechanical vibrations, preventing LED detachment and connector failure over time.

High-Performance Illumination Technology

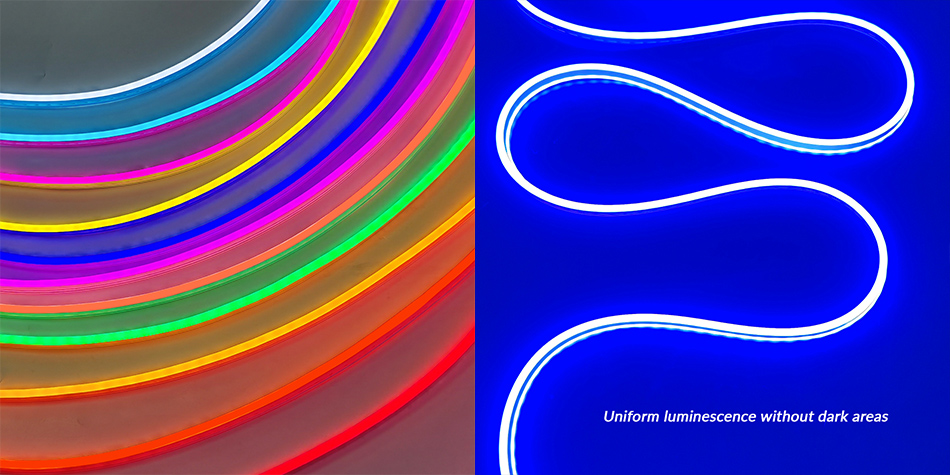

High-Luminance LED Arrays: Surface-mounted LEDs designed for industrial visibility, delivering consistent brightness across long strips to illuminate large storage areas without dark spots.

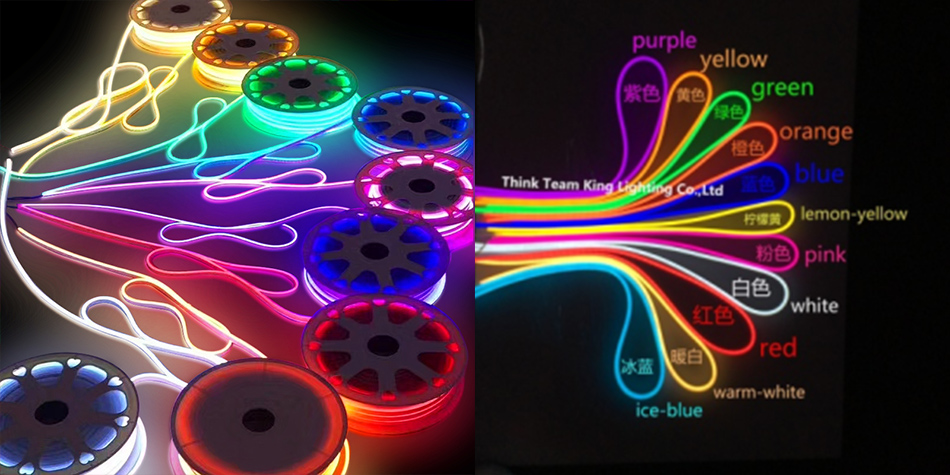

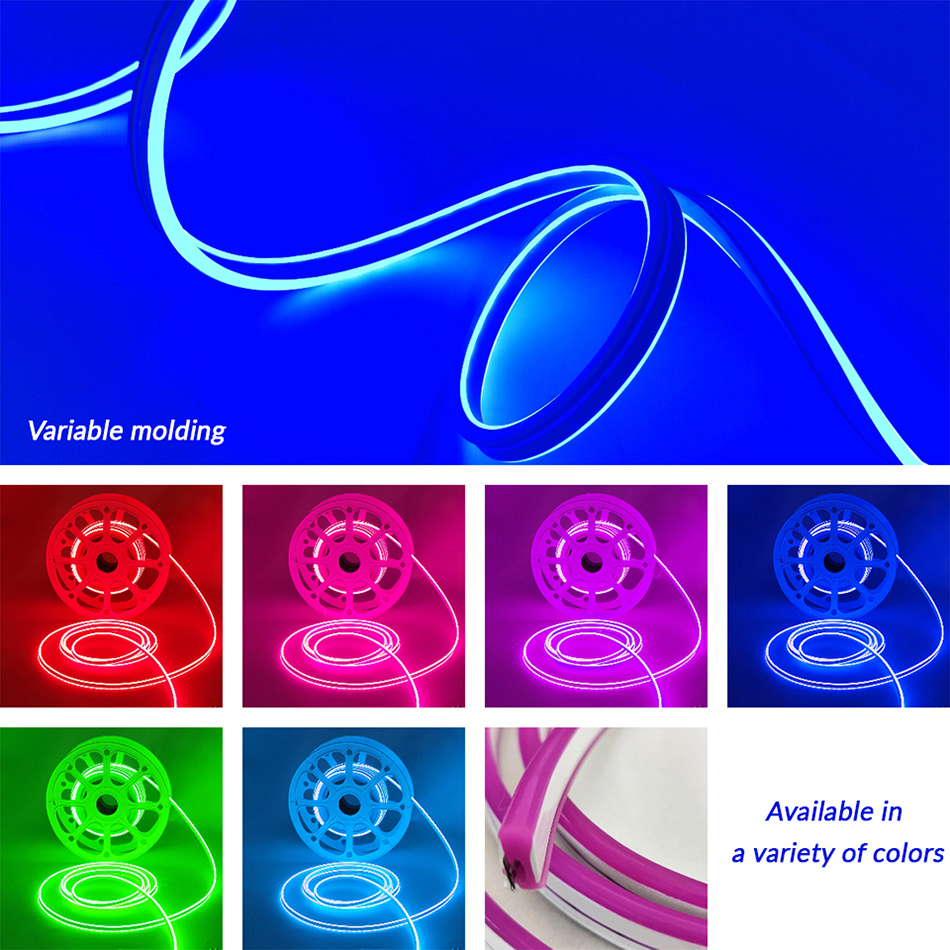

Color Temperature Consistency: Optimal 4000K–5000K cool white output enhances object recognition and reduces eye strain during long shifts, with optional monochromatic red/green variants for safety signaling.

Core Advantages for Warehouse Operations

Adaptability to Complex Warehouse Layouts

Modular Flexibility: Pre-marked cut points and snap-fit connectors allow custom lengths for irregular storage racks, mezzanine structures, or conveyor belt systems, ensuring seamless integration into existing infrastructure.

Tight Radius Bending: Capable of navigating 30mm bend radii around pallet racks, column supports, or automated guided vehicle (AGV) pathways, eliminating lighting 死角 in confined spaces.

Safety and Compliance

Emergency Lighting Integration: Compatible with backup power systems, providing critical illumination during outages to guide workers to emergency exits or safety equipment.

Safety Signage Enhancement: Used to outline hazard zones, loading docks, or pedestrian walkways with high-contrast colors (e.g., red for restricted areas, green for safe passage), improving compliance with OSHA and ISO safety standards.

Energy Efficiency and Cost Savings

Low-Voltage Operation: Runs on 12V/24V DC, reducing energy consumption by up to 60% compared to traditional high-intensity discharge (HID) lighting, with smart controllers enabling motion-activated dimming in low-traffic zones.

Long Operational Life: 50,000+ hours of maintenance-free operation, minimizing downtime for fixture replacement in hard-to-reach warehouse ceilings.

Easy Installation and Retrofitting

Tool-Free Assembly: Adhesive-backed strips or magnetic mounts for quick installation on metal racks, concrete walls, or mezzanine floors, reducing labor costs during retrofitting projects.

Cable Management Solutions: Flat cables and hidden connectors streamline wiring in high-bay warehouses, avoiding interference with overhead cranes or storage systems.

Strategic Applications in Warehouse Zones

Rack and Shelving Illumination

Inventory Management: High-brightness strips mounted along shelf edges or rack columns, illuminating product labels and SKU locations to speed up picking and restocking.

Cold Storage Compatibility: Specialized strips rated for -30°C operation, maintaining flexibility and light output in refrigerated warehouses without compromising performance.

Aisle and Pathway Guidance

Pedestrian and Vehicle Routes: Colored neon strips (e.g., blue for pedestrian paths, yellow for forklift lanes) along floor edges or ceiling tracks, reducing collision risks in high-traffic zones.

Cross-Docking Areas: Weatherproof strips in loading docks to highlight trailer positions and safety barriers, improving coordination during cargo handling.

Equipment and Machinery Lighting

Automation Integration: Mounted on AGVs, conveyors, or robotic arms to indicate operational status , enhancing maintenance visibility.

Control Panel Illumination: Low-profile strips inside control rooms or machinery enclosures, providing task lighting for technicians without heat generation.

Exterior and Perimeter Security

Fence and Gate Lighting: UV-stabilized strips along warehouse perimeters, deterring intruders with consistent illumination while withstanding outdoor elements.

Loading Dock Canopies: IP69K-rated strips under canopies, ensuring visibility during nighttime operations and adverse weather conditions.

Design and Installation Best Practices

Phase 1: Warehouse Zoning and Lighting Audit

Risk Assessment:

Identify high-hazard zones (e.g., forklift paths, heavy machinery areas) and prioritize robust, impact-resistant strips.

Measure ambient light levels in different zones to determine optimal LED density and color temperature.

Layout Planning:

Use 3D modeling to map strip placement on racks, aisles, and equipment, ensuring uniform coverage and minimal shadowing.

Phase 2: Material Selection for Industrial Use

Environment-Specific Specs:

Dusty Warehouses: Choose IP68-rated strips with anti-static coatings to repel particulates.

Freezer Storage: Select silicone-encased strips with low-temperature flexibility and thermal insulation.

Safety Compliance:

Ensure strips meet UL 1598 (Industrial Lighting) and CE EN 60079-0 for hazardous locations (if applicable), especially in warehouses storing flammable materials.

Phase 3: Installation Techniques

Rack Mounting:

Use metal clips or magnetic brackets for easy adjustment on pallet racks, spacing strips every 1–2 meters for uniform illumination.

For concrete ceilings, employ rivets or epoxy anchors to secure heavy-duty strips in high-bay areas.

Electrical Integration:

Use shielded cables to prevent electromagnetic interference (EMI) with warehouse management systems (WMS).

Install surge protectors and ground fault circuit interrupters (GFCI) to safeguard against power fluctuations.

Phase 4: Maintenance and Monitoring

Routine Inspections:

Monthly checks for connector tightness and casing integrity, especially in vibration-prone zones near loading docks.

Annual thermal imaging to identify overheating strips in hard-to-reach areas.

Cleaning Protocols:

Use compressed air or non-abrasive brushes to remove dust from strip surfaces, avoiding water-based cleaners in non-washdown zones.

Key Considerations When Selecting Industrial Flexible Neon Strips

Environmental Resistance

Temperature Range: Confirm operational limits match warehouse conditions (e.g., -20°C to 50°C for general storage, -40°C for freezers).

Chemical Resistance: Silicone strips are ideal for warehouses handling oils or solvents; PVC may suffice in dry, low-contamination environments.

Lighting Performance

Luminous Efficacy: Prioritize strips with >100 lm/W to balance brightness and energy use, critical for large-scale warehouse lighting grids.

Beam Angle: Opt for 120°–150° wide-angle diffusion to minimize shadows on tall racks, with narrow-angle strips for focused task lighting.

Control Systems Integration

IoT Compatibility: Choose strips with Modbus or BACnet protocols for integration with warehouse automation systems, enabling centralized control and energy optimization.

Motion Sensors: Deploy in rarely accessed zones to auto-dim or power off strips, reducing energy waste in inactive areas.

Certification and Standards

Safety Approvals: Mandatory certifications include UL 153 (Portable Lighting) for temporary setups and UL 8750 for permanent installations.

Ergonomic Design: Ensure strips meet ANSI/IESNA RP-27 for glare reduction, protecting worker vision during long shifts.

Supplier Expertise

Industrial Experience: Partner with suppliers who offer vibration testing data and case studies in similar warehouse environments.

Custom Solutions: Suppliers providing pre-bent strips for unique rack configurations or explosion-proof variants for hazardous material storage.

Overcoming Warehouse Lighting Challenges

Challenge 1: Dust and Debris Accumulation

Solution: Regular compressed air cleaning and choosing strips with smooth, non-porous casings to prevent particulate buildup that reduces light transmission.

Challenge 2: Vibration-Induced Failures

Solution: Use anti-vibration mounts and redundant connectors in high-movement areas, paired with quarterly torque checks on mounting hardware.

Challenge 3: Large-Scale Uniformity

Solution: Employ professional lighting designers to calculate optimal strip spacing and power supply placement, ensuring <10% brightness variation across zones.

Challenge 4: Cold Storage Brittleness

Solution: Specify strips with -40°C-rated silicone casings and conduct thermal cycling tests during product selection.

Innovations in Industrial Warehouse Lighting

Smart Industrial IoT Systems

Predictive Maintenance: Sensors embedded in strips monitor temperature, vibration, and power usage, sending alerts for proactive maintenance.

Dynamic Zone Control: AI algorithms adjust strip brightness in real time based on WMS data, dimming in zones with no active inventory.

Sustainable Industrial Design

Energy Harvesting: Solar-powered strips for warehouse exteriors and skylight-integrated systems, reducing reliance on grid power in remote facilities.

Recycled Materials: Strips made with 30% post-industrial recycled silicone, aligning with corporate sustainability goals.

Advanced Thermal Management

Graphene-Enhanced PCBs: Emerging technology that improves heat dissipation by 50%, enabling higher brightness in compact warehouse spaces.

Liquid-Cooled Strips: Experimental designs for extreme heat environments, using micro-channel cooling to maintain performance near boilers or furnaces.

Conclusion: Industrial Flexible Neon Strips as a Warehouse Asset

Industrial flexible neon strips have evolved into a cornerstone of modern warehouse operations, delivering a rare combination of durability, adaptability, and energy efficiency. By addressing the unique challenges of storage environments—from dust and vibration to large-scale uniformity—these systems enhance worker safety, streamline inventory management, and reduce operational costs.

As warehouses continue to embrace automation and sustainability, industrial flexible neon strips stand out for their ability to integrate with smart systems, endure harsh conditions, and provide customizable illumination. By prioritizing quality, compliance, and innovative design, logistics providers can transform their storage facilities into safer, more efficient environments—proving that industrial lighting is not just a necessity, but a strategic asset in the supply chain landscape.