Time:2025-06-30

In environments where exposure to moisture, chemicals, and corrosive substances is prevalent, finding a reliable lighting solution is crucial. The IP67 silicone neon strip with an anti - corrosion coating emerges as a game - changer, offering a combination of robust waterproof and dustproof capabilities along with enhanced protection against corrosion. This article will comprehensively explore these specialized neon strips, covering their construction, key features, diverse applications, installation considerations, maintenance requirements, and future trends, highlighting their significance in various industries and settings.

Construction and Technology of IP67 Silicone Neon Strip with Anti - Corrosion Coating

The Silicone Encapsulation

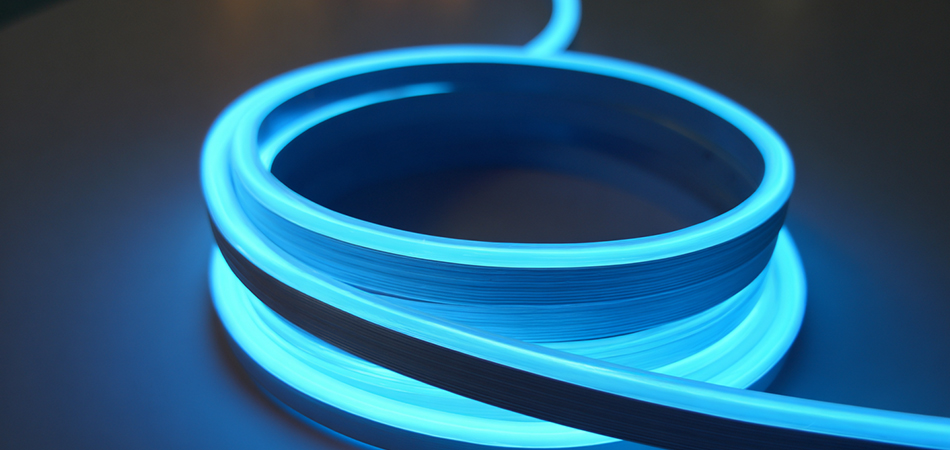

The outer layer of the IP67 silicone neon strip is crafted from high - quality silicone material. This silicone provides a flexible yet durable protective barrier, ensuring the strip meets the IP67 standard. It effectively seals out water and dust, preventing ingress that could damage the internal components. The silicone's flexibility allows for easy installation on various surfaces, whether curved, flat, or irregular, making it adaptable to a wide range of installation requirements.

The Anti - Corrosion Coating

What sets this neon strip apart is the anti - corrosion coating applied to the silicone exterior. This coating is formulated using advanced materials and techniques. It creates an additional layer of defense, specifically designed to resist the harmful effects of corrosive agents such as saltwater, chemicals, and acidic substances. The coating bonds tightly with the silicone, forming a seamless shield that adheres well even under harsh conditions.

The anti - corrosion coating has a smooth surface that repels liquids and prevents them from lingering on the strip, reducing the contact time of corrosive substances. It also has excellent chemical resistance properties, maintaining its integrity when exposed to a variety of industrial chemicals, thereby safeguarding the silicone and the internal LED components from degradation.

The LED Lighting Components and Internal Structure

At the core of the strip are carefully selected LED chips, chosen for their high - performance and reliability. These LEDs are arranged in a precise pattern on a circuit board, which is then encased within the silicone and protected by the anti - corrosion coating. The internal circuitry is designed to ensure stable power supply to the LEDs, enabling consistent and bright illumination.

The components are also engineered to work in harmony with the protective layers, with proper insulation and heat - dissipation mechanisms in place. This ensures that the LEDs can operate efficiently even in challenging environments, without being affected by the external conditions that the anti - corrosion coating and silicone are designed to withstand.

Key Features and Benefits of IP67 Silicone Neon Strip with Anti - Corrosion Coating

Superior Corrosion Resistance

The most significant feature of this neon strip is its exceptional anti - corrosion ability. In environments like coastal areas, chemical plants, or food processing facilities where corrosive elements are present, the anti - corrosion coating acts as a safeguard. It prevents the silicone from deteriorating due to salt spray, chemical spills, or exposure to acidic fumes, ensuring the long - term functionality of the strip.

This corrosion resistance not only extends the lifespan of the neon strip but also reduces the need for frequent replacements, resulting in cost savings for users. It provides peace of mind, knowing that the lighting solution can withstand the harsh conditions of the environment without compromising on performance.

IP67 - Rated Waterproof and Dustproof Performance

In addition to corrosion resistance, the IP67 rating offers outstanding waterproof and dustproof capabilities. The strip can withstand temporary submersion in water, making it suitable for use in areas prone to water splashes, rain, or even partial flooding. It is also completely protected against dust ingress, ensuring that the internal components remain clean and free from damage caused by dust particles.

This dual protection is vital in many industrial and outdoor applications, where exposure to water and dust is common. Whether it's used in outdoor lighting for marinas, or in industrial settings with high - dust environments, the IP67 silicone neon strip with anti - corrosion coating can operate reliably.

Durability and Long - Term Reliability

Combining the robust silicone encapsulation, anti - corrosion coating, and reliable LED components, these neon strips offer remarkable durability. They can endure mechanical stress, vibrations, and impacts that are typical in various applications. The materials used are resistant to wear and tear, maintaining their integrity over time.

The long - term reliability of the strip is a significant advantage, especially in applications where continuous lighting is required. It reduces the risk of unexpected failures, minimizing downtime and disruption to operations. This makes it a preferred choice for industries where reliable lighting is crucial for safety, productivity, and functionality.

Energy Efficiency and Aesthetic Appeal

Despite their advanced protective features, these neon strips are highly energy - efficient. The LED technology used consumes significantly less power compared to traditional lighting sources, helping users save on electricity costs. This energy efficiency also contributes to environmental sustainability, aligning with the growing trend of green initiatives.

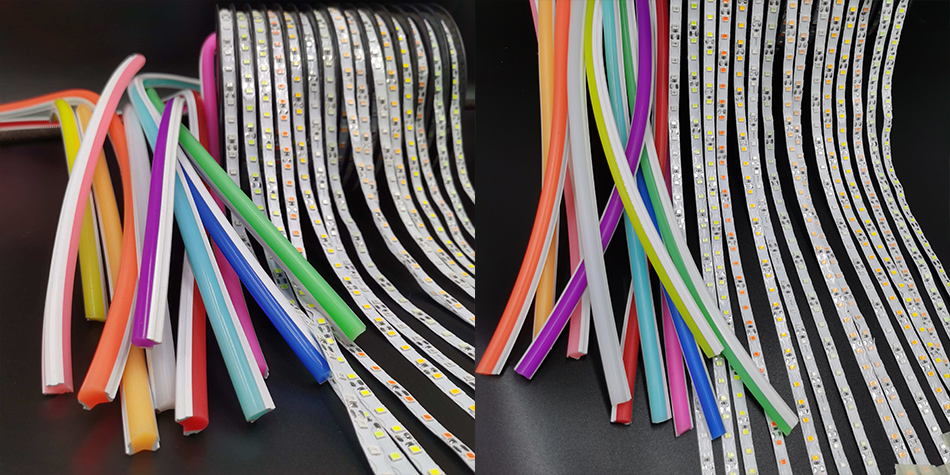

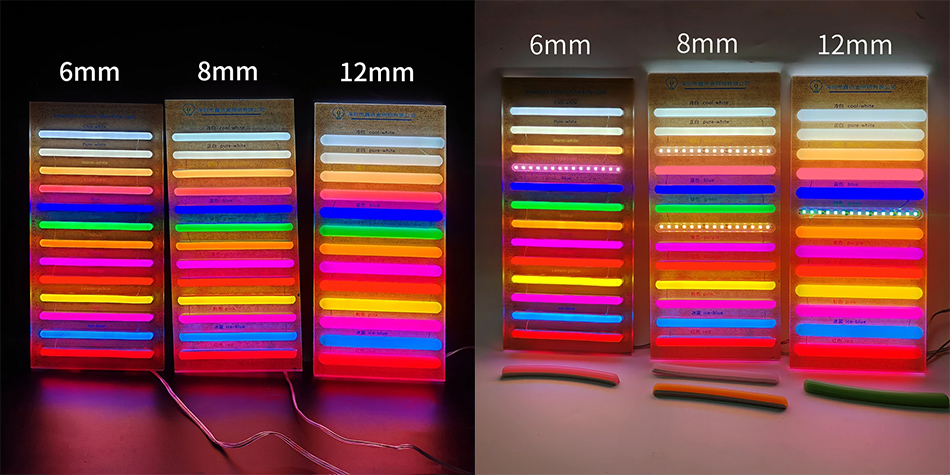

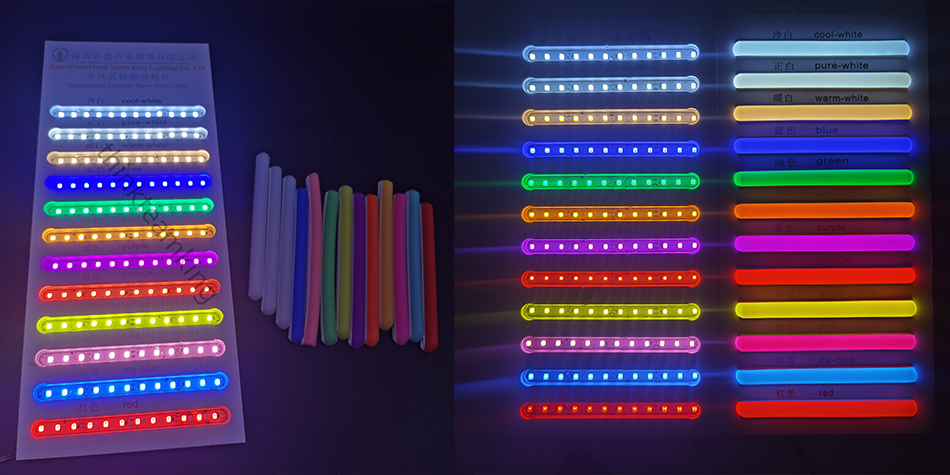

Moreover, the neon strips come in a variety of colors and can be used to create different lighting effects. They offer aesthetic versatility, whether it's for enhancing the ambiance of a commercial space, creating eye - catching signage, or adding decorative lighting to outdoor areas. Their flexibility allows for creative installation designs, making them not only functional but also visually appealing.

Applications of IP67 Silicone Neon Strip with Anti - Corrosion Coating

Marine and Coastal Applications

In marine environments, such as on ships, boats, docks, and coastal buildings, the IP67 silicone neon strip with anti - corrosion coating is an ideal lighting solution. The constant exposure to saltwater, sea spray, and high humidity can quickly corrode ordinary lighting products. However, these neon strips, with their anti - corrosion coating, can withstand these harsh conditions.

They can be used for various purposes, including deck lighting, navigation lighting, and highlighting architectural features of coastal structures. The waterproof and dustproof properties also ensure that the strips remain functional even in the face of heavy rain or strong winds, providing reliable lighting for safety and aesthetics.

Industrial Settings

In industrial plants, factories, and manufacturing facilities, there are often exposure to chemicals, dust, and moisture. Chemical plants, in particular, deal with a wide range of corrosive substances. The anti - corrosion coating on these neon strips protects them from chemical spills and fumes, while the IP67 rating keeps out dust and water.

They can be installed for general illumination, task lighting at workstations, or for safety and signaling purposes. For example, in areas where hazardous materials are handled, the neon strips can be used to mark safety zones or to provide clear lighting for emergency exits, ensuring the safety of workers in these challenging environments.

Food and Beverage Processing Plants

Food and beverage processing plants have strict hygiene requirements and are often exposed to moisture, cleaning agents, and acidic substances during the production and cleaning processes. The IP67 silicone neon strip with anti - corrosion coating is suitable for use in these settings as it can resist the corrosive effects of these substances.

It can be installed in production areas, storage rooms, and packaging facilities to provide safe and reliable lighting. The dustproof and waterproof features also make it easy to clean, helping to maintain the high - hygiene standards required in the food and beverage industry.

Outdoor Commercial and Decorative Applications

For outdoor commercial spaces, such as shopping malls, restaurants with outdoor seating, and entertainment venues, these neon strips offer both functionality and aesthetic appeal. The anti - corrosion coating protects them from the elements, including rain, UV rays, and pollutants in the air.

They can be used for decorative lighting, highlighting storefronts, creating unique lighting displays, or for providing ambient lighting in outdoor areas. Their ability to withstand various weather conditions ensures that they remain operational and visually appealing throughout the year, enhancing the overall customer experience.

Installation Considerations for IP67 Silicone Neon Strip with Anti - Corrosion Coating

Surface Preparation

Before installation, proper surface preparation is essential. The surface where the neon strip will be attached should be clean, dry, and free of any dirt, grease, or existing coatings that could affect adhesion. In corrosive environments, it may be necessary to use a degreaser or a specialized cleaner to ensure the surface is thoroughly cleaned.

For rough or uneven surfaces, additional preparation such as sanding or applying a primer may be required to create a smooth and suitable surface for installation. This helps to ensure a strong and long - lasting bond between the strip and the surface, maximizing the effectiveness of the installation.

Electrical Connection

Connecting the neon strip to the electrical supply requires careful attention to safety and proper installation procedures. A suitable power supply that meets the voltage and current requirements of the strip should be selected. All electrical connections should be made using waterproof connectors and enclosures to maintain the IP67 rating and prevent electrical hazards.

The wiring should be routed in a way that protects it from damage, such as being pinched, abraded, or exposed to corrosive substances. It is advisable to follow the manufacturer's instructions carefully during the electrical connection process, and if in doubt, consult a professional electrician, especially in complex or industrial installations.

Mounting and Securing the Strip

There are different methods for mounting and securing the IP67 silicone neon strip. Some strips come with an adhesive backing that can be used for quick and easy installation on smooth surfaces. However, in more demanding environments or for more permanent installations, mechanical fasteners such as screws, clips, or brackets may be required.

When using mechanical fasteners, care should be taken not to damage the anti - corrosion coating or the silicone casing. The strip should be installed in a way that allows for proper heat dissipation of the LED components, as excessive heat can affect their performance and lifespan. Additionally, ensure that the mounting method does not compromise the waterproof and dustproof integrity of the strip.

Maintenance and Troubleshooting of IP67 Silicone Neon Strip with Anti - Corrosion Coating

Regular Inspection

Regular inspection of the neon strip is crucial to ensure its optimal performance. Periodically, visually inspect the strip for any signs of damage, such as cracks in the silicone, peeling of the anti - corrosion coating, loose connections, or a decrease in light output. In corrosive environments, more frequent inspections may be necessary.

Check the electrical connections for signs of corrosion or looseness, as these can lead to electrical failures. Promptly address any issues detected during the inspection to prevent further damage and ensure the continued reliability of the lighting solution.

Cleaning

Cleaning the IP67 silicone neon strip with anti - corrosion coating is relatively straightforward. Use a soft, damp cloth to wipe away dust, dirt, or any residues on the surface. In case of more stubborn stains or contaminants, a mild, non - abrasive cleaner can be used.

Avoid using harsh chemicals or abrasive materials that could damage the anti - corrosion coating or the silicone. After cleaning, ensure that the strip is completely dry before restoring power to prevent any potential electrical problems.

Troubleshooting Common Issues

If the neon strip experiences problems such as flickering, dimming, or failure to turn on, start by checking the electrical connection. Ensure that the power supply is functioning correctly and that all connections are secure and waterproof.

If the electrical connection is fine, check for any physical damage to the strip. A damaged LED chip, a break in the silicone casing, or a malfunctioning driver can all cause issues. In some cases, if only a section of the strip is not working, it may be possible to isolate and repair the problem. However, if the entire strip is malfunctioning, refer to the manufacturer's troubleshooting guide or contact customer support for assistance.

Trends and Future Developments in IP67 Silicone Neon Strip with Anti - Corrosion Coating

Smart Lighting Integration

The future of these neon strips is likely to see increased integration with smart lighting systems. Smart technology allows for remote control and monitoring of the strips, enabling users to adjust the brightness, color, and lighting patterns from a smartphone, tablet, or other smart devices.

This integration can also enable features such as scheduling, where the strips can be set to turn on and off at specific times, and sensor - based control, where the lighting can respond to environmental conditions or occupancy. In industrial applications, smart lighting systems can provide real - time data on the performance and status of the neon strips, facilitating predictive maintenance and improving overall efficiency.

Advancements in Anti - Corrosion Coating Technology

As technology continues to evolve, there will be advancements in anti - corrosion coating technology. Newer coatings may offer even better resistance to a wider range of corrosive substances, enhanced durability, and improved adhesion to the silicone.

Research may also focus on developing self - healing anti - corrosion coatings that can repair minor damages automatically, further extending the lifespan of the neon strips. These advancements will make the strips even more reliable and suitable for use in increasingly harsh and corrosive environments.

Sustainable and Eco - Friendly Solutions

With the growing emphasis on sustainability, there is a trend towards developing more sustainable and eco - friendly IP67 silicone neon strips with anti - corrosion coatings. This may involve the use of recycled materials in the production of the silicone and the coating, as well as the development of more environmentally friendly manufacturing processes.

Manufacturers may also focus on reducing the overall environmental impact of the product, from production to disposal. For example, developing coatings that are more easily recyclable or using less harmful chemicals in the coating formulation. These sustainable initiatives will not only benefit the environment but also meet the increasing demand from consumers and industries for more responsible products.

In conclusion, the IP67 silicone neon strip with anti - corrosion coating offers a reliable, durable, and versatile lighting solution for environments where corrosion, water, and dust are major concerns. Its unique combination of features makes it suitable for a wide range of applications across various industries. As technology progresses and trends in smart integration, material innovation, and sustainability emerge, these neon strips are set to become even more advanced and widely used, providing enhanced protection and functionality in challenging environments.