Time:2025-06-28

In the specialized realm of lighting solutions, IP69K - rated waterproof silicone neon lighting stands out as a premium choice for environments where extreme protection against dust, water, and harsh conditions is required. This stringent rating indicates the lighting's ability to withstand the most challenging circumstances, making it indispensable in various industries. From food processing facilities to automotive manufacturing plants, IP69K - rated waterproof silicone neon lighting offers a combination of durability, functionality, and aesthetic appeal. This article will comprehensively explore this advanced lighting solution, covering its rating standards, construction, features, applications, installation, maintenance, and future trends.

Understanding the IP69K Rating Standard

The IP Code System

The IP (Ingress Protection) code is an internationally recognized standard that classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures against intrusion from foreign bodies such as dust, accidental contact, and water. The code consists of the letters "IP" followed by two digits. The first digit represents the level of protection against solid objects, while the second digit indicates the level of protection against water.

Decoding the IP69K Rating

For IP69K - rated waterproof silicone neon lighting, the first digit "6" signifies complete protection against dust ingress. This means that no dust particles can enter the lighting enclosure, ensuring that the internal components remain clean and free from damage caused by dust accumulation. The second digit "9" represents the highest level of water protection. IP69K - rated products can withstand high - pressure, high - temperature water jets from close range, typically used in industrial cleaning processes. The "K" suffix further emphasizes the ability to resist high - temperature steam cleaning, which is common in industries where strict hygiene standards are required.

Significance of the IP69K Rating

The IP69K rating is of utmost importance in industries where lighting is exposed to harsh environmental conditions. It ensures the reliability and longevity of the lighting system, reducing the risk of malfunctions due to dust or water ingress. In addition, it allows for easy and thorough cleaning, which is crucial in maintaining hygiene standards in sectors such as food and beverage, pharmaceuticals, and automotive manufacturing.

Construction and Technology of IP69K-Rated Waterproof Silicone Neon Lighting

Silicone Encapsulation

The outer layer of IP69K - rated waterproof silicone neon lighting is made from high - quality, specialized silicone. This silicone is engineered to provide an impenetrable barrier against dust and water. It has excellent flexibility, allowing the lighting to be bent and shaped to fit various installation requirements while maintaining its integrity.

The silicone casing is resistant to a wide range of temperatures, from extreme cold to high heat, which is essential for withstanding the high - temperature water jets and steam cleaning associated with the IP69K rating. It also offers good chemical resistance, protecting the lighting from the effects of cleaning agents and other chemicals commonly used in industrial cleaning processes.

LED Lighting Components

Inside the silicone casing, the LED chips are carefully selected for their high performance and reliability. These LEDs are designed to operate efficiently in harsh environments, with excellent resistance to moisture, temperature fluctuations, and vibration.

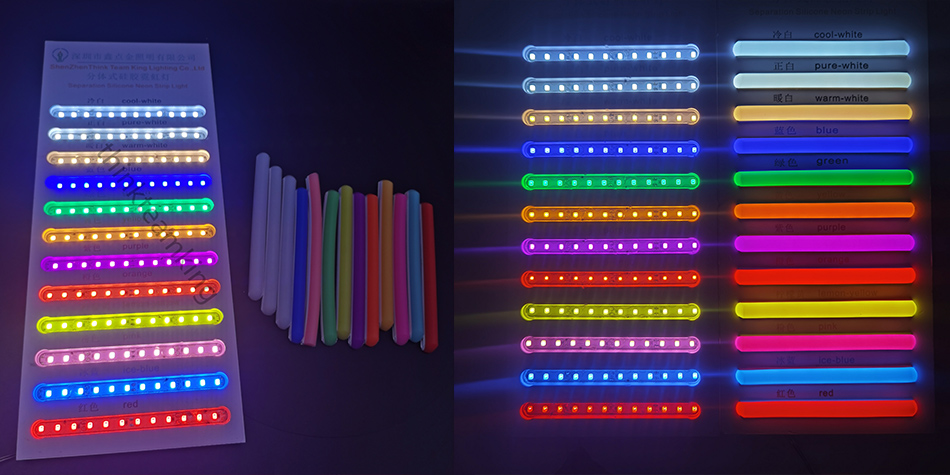

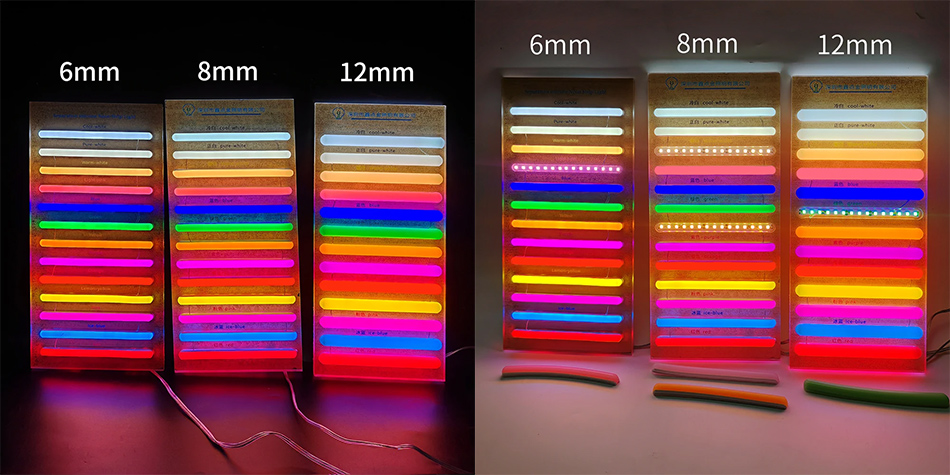

Like other high - quality LED lighting, IP69K - rated silicone neon lighting offers energy efficiency, a long lifespan, and a wide range of color options. Whether for general illumination, accent lighting, or creating specific visual effects, the LED components can deliver consistent and vibrant lighting output.

Sealing and Waterproofing Mechanisms

To achieve the IP69K rating, advanced sealing and waterproofing mechanisms are employed. All joints, connections, and openings in the lighting fixture are meticulously sealed to prevent any ingress of dust or water. Specialized gaskets, O - rings, and seals are used at critical points to ensure a watertight and dust - tight enclosure.

The electrical connections are also protected with waterproof connectors and enclosures, ensuring that the lighting can be safely used in wet environments without the risk of electrical short - circuits or malfunctions. These robust sealing and waterproofing features are what enable the lighting to withstand the rigorous cleaning processes associated with the IP69K rating.

Key Features and Benefits of IP69K-Rated Waterproof Silicone Neon Lighting

Extreme Protection

The most prominent feature of IP69K - rated waterproof silicone neon lighting is its unparalleled protection against dust and water. This level of protection ensures that the lighting can operate reliably in the harshest of environments, from industrial kitchens with high humidity and frequent cleaning to outdoor installations exposed to heavy rain and dust storms.

The ability to withstand high - pressure, high - temperature water jets and steam cleaning means that the lighting can be easily maintained and cleaned, reducing the risk of contamination and ensuring compliance with strict hygiene standards in various industries.

Durability and Longevity

Combining the robust silicone casing and the well - protected LED components, IP69K - rated waterproof silicone neon lighting offers exceptional durability. It can resist physical impacts, abrasion, and the wear - and - tear associated with continuous operation in demanding environments.

The long lifespan of the LED components, coupled with the reliable protection against environmental factors, means that the lighting requires minimal maintenance and replacement over time. This not only reduces operational costs but also minimizes downtime, which is crucial in industrial settings where continuous lighting is essential.

Energy Efficiency

Despite its advanced protection features, IP69K - rated waterproof silicone neon lighting is highly energy - efficient. The LED technology used consumes significantly less power compared to traditional lighting sources, such as incandescent or fluorescent lights.

This energy efficiency translates into cost savings for users, especially in large - scale industrial applications where numerous lighting fixtures are in use. Additionally, the reduced energy consumption contributes to environmental sustainability by lowering carbon emissions.

Aesthetic and Functional Flexibility

IP69K - rated waterproof silicone neon lighting is not only practical but also aesthetically versatile. It comes in a variety of colors and can be customized to create different lighting effects, from soft ambient glows to vibrant and attention - grabbing displays.

This flexibility allows it to be used for both functional lighting, such as illuminating work areas in industrial facilities, and decorative lighting, such as enhancing the visual appeal of commercial spaces or outdoor landscapes. Its ability to adapt to different design requirements makes it a popular choice across various industries.

Applications of IP69K-Rated Waterproof Silicone Neon Lighting

Food and Beverage Industry

In the food and beverage industry, maintaining strict hygiene standards is paramount. IP69K - rated waterproof silicone neon lighting is ideal for use in food processing plants, breweries, and restaurants. It can withstand the frequent and intensive cleaning processes, including high - pressure steam cleaning, without compromising its performance or integrity.

The lighting can be installed in production areas, storage facilities, and food preparation zones, providing reliable illumination while ensuring that no dust or water can contaminate the food products. Its aesthetic flexibility also allows for the creation of a clean and inviting environment for both employees and customers.

Pharmaceutical and Healthcare Facilities

Pharmaceutical and healthcare facilities also require lighting solutions that can meet stringent hygiene and cleanliness standards. IP69K - rated waterproof silicone neon lighting is suitable for use in cleanrooms, laboratories, and operating theaters.

It can be easily cleaned and disinfected, reducing the risk of microbial contamination. The lighting's durability and reliability are also important in these settings, where uninterrupted illumination is crucial for the safety and well - being of patients and the proper functioning of medical procedures.

Automotive Manufacturing Plants

Automotive manufacturing plants are harsh environments with exposure to dust, debris, and various chemicals used in the production process. IP69K - rated waterproof silicone neon lighting can be used in assembly lines, paint shops, and inspection areas.

It can withstand the high - pressure cleaning processes used to keep the production areas clean and free from contaminants. The lighting's ability to operate reliably in these challenging conditions ensures that workers have adequate illumination to perform their tasks safely and efficiently.

Outdoor and Marine Applications

For outdoor and marine applications, where lighting is exposed to the elements, IP69K - rated waterproof silicone neon lighting offers excellent protection. It can be used in outdoor signage, marinas, and coastal installations.

The lighting can withstand heavy rain, saltwater spray, and high humidity, ensuring that it remains functional and maintains its visual appeal over time. Its flexibility also allows for creative installation designs to enhance the aesthetic of outdoor and marine environments.

Installation Considerations for IP69K-Rated Waterproof Silicone Neon Lighting

Surface Preparation

Before installing IP69K - rated waterproof silicone neon lighting, proper surface preparation is essential. The installation surface should be clean, dry, and free of any debris, grease, or contaminants. In industrial settings, where the lighting may be exposed to chemicals or residues, the surface may need to be degreased and thoroughly cleaned.

For outdoor installations, the surface should be able to support the weight of the lighting fixture and withstand the environmental conditions. Rough or uneven surfaces may require additional treatment, such as sanding or the application of a primer, to ensure a secure and stable installation.

Electrical Connection

Electrical connections for IP69K - rated waterproof silicone neon lighting must be made with care to ensure safety and reliability. A suitable power supply that meets the lighting's requirements should be selected, and all electrical connections should be made in accordance with local electrical codes and standards.

Waterproof electrical connectors and enclosures should be used to protect the connections from water ingress. The wiring should be routed in a way that minimizes the risk of damage and ensures proper insulation. It is advisable to consult a professional electrician for complex installations to ensure that all electrical work is done correctly.

Mounting and Securing the Lighting

There are various methods for mounting and securing IP69K - rated waterproof silicone neon lighting, depending on the application and the installation surface. Some lighting fixtures may come with adhesive backing for easy installation on smooth surfaces, while others may require the use of mechanical fasteners, such as screws or clips.

When using mechanical fasteners, care should be taken not to damage the waterproof seals or the silicone casing. The lighting should be mounted in a way that allows for proper heat dissipation, as excessive heat can affect the performance and lifespan of the LED components. In outdoor or high - vibration environments, additional measures may be needed to ensure the stability of the installation.

Maintenance and Troubleshooting of IP69K-Rated Waterproof Silicone Neon Lighting

Regular Inspection

Regular inspection is crucial to ensure the optimal performance of IP69K - rated waterproof silicone neon lighting. Periodically, the lighting fixtures should be visually inspected for any signs of damage to the silicone casing, such as cracks, tears, or signs of wear. The electrical connections should also be checked for looseness, corrosion, or any signs of damage.

In industrial settings, where the lighting may be exposed to harsh cleaning agents or chemicals, more frequent inspections may be required. Any issues detected during the inspection should be addressed promptly to prevent further damage and ensure the continued reliability of the lighting system.

Cleaning

Cleaning IP69K - rated waterproof silicone neon lighting is relatively straightforward due to its high level of water resistance. In most cases, a soft, damp cloth can be used to wipe away dust, dirt, or grime from the surface of the lighting fixture.

For more thorough cleaning, especially in industrial applications, high - pressure water jets or steam cleaning can be used. However, it is important to follow the manufacturer's instructions regarding the cleaning process to avoid damaging the lighting. After cleaning, the lighting should be allowed to dry completely before being put back into operation.

Troubleshooting Common Issues

If IP69K - rated waterproof silicone neon lighting experiences problems, such as flickering, dimming, or failure to turn on, there are several common issues to check. First, verify the electrical connection to ensure that the power supply is functioning correctly and that all connections are secure and waterproof.

If the electrical connection is fine, check for any physical damage to the lighting fixture. A damaged LED chip, a break in the silicone casing, or a malfunctioning driver can all cause problems. In some cases, if only a section of the lighting is not working, it may be possible to isolate and repair the problem. However, if the entire fixture is malfunctioning, it may need to be replaced. Refer to the manufacturer's troubleshooting guide for specific instructions on resolving these issues.

Trends and Future Developments in IP69K-Rated Waterproof Silicone Neon Lighting

Integration with Smart Lighting Systems

The future of IP69K - rated waterproof silicone neon lighting is likely to see increased integration with smart lighting systems. Smart lighting technology allows for remote control and monitoring of the lighting fixtures, enabling users to adjust the brightness, color, and lighting effects from a distance.

This integration can also enable features such as scheduling, where the lighting can be set to turn on and off at specific times, and sensor - based control, where the lighting can respond to environmental conditions or occupancy. Smart lighting systems can enhance the functionality and energy efficiency of IP69K - rated waterproof silicone neon lighting, making it more convenient and cost - effective for users.

Advancements in Materials and Manufacturing

As technology continues to evolve, we can expect significant advancements in the materials and manufacturing processes of IP69K - rated waterproof silicone neon lighting. Newer silicone materials may offer even better protection against dust, water, and chemicals, as well as improved flexibility and durability.

In terms of LED technology, there may be developments in LED chips that offer higher brightness levels, better color rendering, and improved energy efficiency. These advancements will make IP69K - rated waterproof silicone neon lighting more powerful, energy - saving, and visually appealing, further expanding its applications in various industries.

Sustainable and Eco - Friendly Solutions

With the growing emphasis on sustainability and environmental protection, there is a trend towards developing more sustainable and eco - friendly IP69K - rated waterproof silicone neon lighting solutions. This may involve the use of recycled materials in the production of the silicone casing and other components, as well as the development of more energy - efficient manufacturing processes.

Manufacturers may also focus on reducing the environmental impact of the lighting throughout its lifecycle, from production to disposal. The development of sustainable and eco - friendly solutions will not only benefit the environment but also meet the growing demand from consumers and industries for more environmentally responsible products.

In conclusion, IP69K - rated waterproof silicone neon lighting is a highly specialized and reliable lighting solution for demanding environments. Its exceptional protection, durability, energy efficiency, and aesthetic flexibility make it a valuable asset in various industries. As technology continues to advance, we can expect this lighting solution to become even more sophisticated and widely used, with exciting developments in smart integration, material advancements, and sustainability on the horizon.