Time:2025-06-27

Neon strip lights have long been a captivating presence in the world of illumination, seamlessly blending functionality with artistic allure. From their humble beginnings as a novel lighting concept to their current status as a versatile and widely - adopted solution across diverse industries, these lights have continuously evolved. This article provides an in - depth exploration of neon strip lights, covering their historical background, technological fundamentals, different types, extensive applications, installation and maintenance procedures, as well as emerging trends and future prospects, all while maintaining high industry professionalism and ensuring search engine optimization.

The Evolutionary Journey of Neon Strip Lights

The story of neon strip lights traces back to the discovery of neon gas in the late 19th century. Scientists Sir William Ramsay and Morris Travers first isolated neon in 1898, and they observed that when an electric current passed through this gas within a sealed tube, it emitted a striking red - orange glow. This discovery laid the groundwork for the development of neon - based lighting technology.

In 1910, French engineer Georges Claude made a significant breakthrough by creating the first commercial neon lights. These initial neon lights were predominantly used for advertising purposes, quickly becoming a popular choice for businesses looking to attract customers. The first neon sign, promoting "Cinzano," was installed in Paris, immediately capturing public attention. Over time, technological advancements led to the creation of more flexible and adaptable neon strip lights, expanding their reach beyond advertising into various other sectors such as interior design, architecture, and entertainment.

Unveiling the Technology Behind Neon Strip Lights

The Gas - Discharge Principle

Neon strip lights operate on the principle of gas - discharge lighting. At the core of these lights is a long, narrow glass tube filled with a low - pressure inert gas, typically neon, argon, or a mixture of both. Electrodes are positioned at each end of the tube. When a high - voltage electrical current is applied between these electrodes, the gas inside the tube ionizes, creating a plasma of charged particles. As electrons within the plasma are accelerated towards the positive electrode, they collide with gas atoms. These collisions cause the electrons in the gas atoms to jump to higher energy levels. When these excited electrons return to their original lower energy states, they release energy in the form of photons, which we perceive as light.

Color Generation Mechanisms

The color of the light emitted by neon strip lights depends on the type of gas used and additional elements within the tube. Pure neon gas emits a characteristic red - orange hue. However, by using different gases or combinations, and by applying fluorescent coatings to the inside of the glass tube, a vast spectrum of colors can be achieved. For instance, argon combined with mercury vapor can produce a blue - green light. This ability to generate a wide range of colors gives neon strip lights great versatility in creating different visual effects.

Power Supply and Electrical Systems

Neon strip lights require a specialized power supply system. Due to the high voltage needed to ionize the gas within the tubes, transformers are commonly used to step up the standard electrical voltage. The power supply must be carefully designed to ensure a stable and consistent current flow to the neon strips, as fluctuations can affect the light output and potentially damage the strips. Additionally, proper insulation and grounding are crucial for safety, especially when dealing with high - voltage systems.

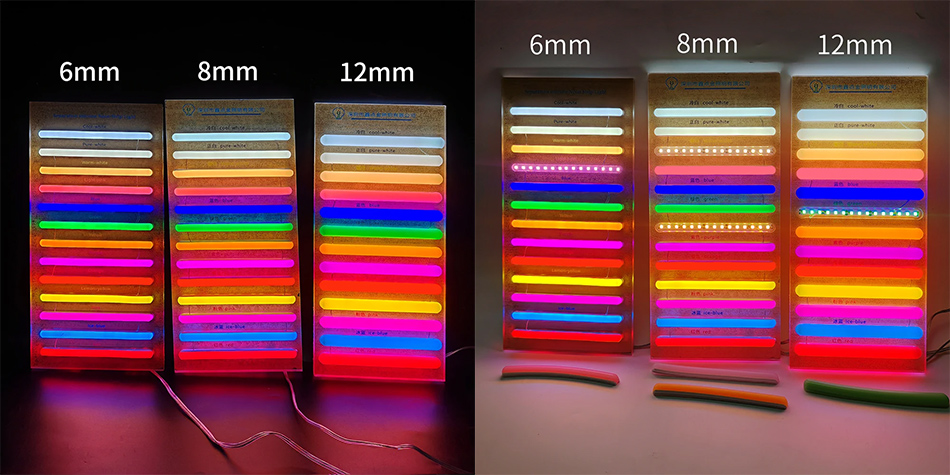

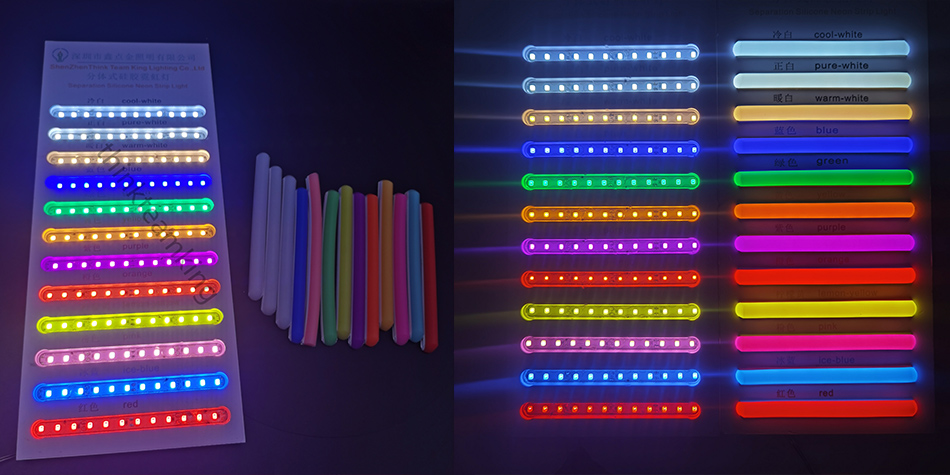

Diverse Types of Neon Strip Lights

Traditional Glass - Tube Neon Strip Lights

Traditional neon strip lights are crafted from glass tubes that are skillfully bent and shaped into various forms. These lights are renowned for their intense and bright glow, as well as their long - lasting performance. The glass tubes provide a durable enclosure for the gas, but they are relatively fragile and require careful handling. The manufacturing process of traditional neon strip lights is complex, involving techniques such as glassblowing and electrode sealing. Despite their fragility, they are still highly valued for their classic aesthetic and are often used in high - end signage and decorative applications where a unique and eye - catching look is desired.

LED - Based Neon Strip Lights

In recent years, LED - based neon strip lights have gained significant popularity as a modern alternative to traditional glass - tube neon. These lights utilize light - emitting diodes (LEDs) to produce light. LEDs offer several advantages over traditional neon. They are more energy - efficient, consuming less power while still providing bright and vivid illumination. LED - based neon strips are also more durable, as they are less prone to breakage compared to glass - tube neon. They come in a wide variety of colors and can support dynamic lighting effects, such as color - changing and flashing, through advanced control systems. Their flexibility and ease of installation make them a preferred choice for many applications, from home decor to commercial projects.

Cold - Cathode Neon Strip Lights

Cold - cathode neon strip lights represent another type of neon lighting technology. In cold - cathode tubes, the electrodes do not rely on heating to emit electrons, unlike in traditional incandescent bulbs. Instead, electrons are emitted from the cathode through the application of a high - voltage electric field. Cold - cathode neon strip lights are known for their long lifespan and high luminous efficiency. They can produce a bright and uniform light, making them suitable for applications where high - quality illumination is required, such as backlighting for displays, signage in indoor environments, and architectural lighting where a consistent light output is essential.

Extensive Applications of Neon Strip Lights

Advertising and Signage

One of the most common and prominent applications of neon strip lights is in advertising and signage. Their bright and attention - grabbing nature makes them ideal for creating eye - catching signs that can attract customers from a distance. Businesses of all types, from small local stores to large international brands, use neon strip lights to display their logos, names, and promotional messages. Neon signs can be customized in various shapes, sizes, and colors, allowing for creative and unique designs that stand out in crowded urban environments. They are often used on storefronts, billboards, and in window displays to draw the attention of passersby and enhance brand visibility.

Interior Design and Decoration

In the realm of interior design, neon strip lights are used to add a touch of style and personality to spaces. They can serve as accent lighting, highlighting architectural features, artwork, or decorative elements within a room. For example, neon strip lights can be installed along the edges of shelves to illuminate displayed items, or around the perimeter of a room to create a soft, ambient glow. In modern interior design, LED - based neon strips are particularly popular due to their flexibility and ability to create dynamic lighting effects. They can be used to set different moods in a space, such as a warm and cozy atmosphere in a living room or a vibrant and energetic vibe in a home theater or entertainment area.

Architectural Lighting

Neon strip lights play a crucial role in architectural lighting, both indoors and outdoors. On the exterior of buildings, they can be used to outline the architectural features, such as the edges of roofs, windows, and doors, creating a striking visual effect at night. Neon strip lights can also be used to illuminate the facade of a building, highlighting its unique design elements and making it more visible and appealing. Indoors, they are used to light up staircases, corridors, and common areas, providing both functionality and aesthetic appeal. In some cases, neon strip lights are integrated into the architectural design of a building from the initial planning stages, becoming an integral part of the structure's overall look and feel.

Entertainment and Events

In the entertainment industry, neon strip lights are widely used to create immersive and visually stunning experiences. In nightclubs, bars, and music venues, neon strip lights are used to set the mood and create a vibrant atmosphere. Their dynamic lighting effects, such as color - changing and flashing, can be synchronized with the music, enhancing the overall entertainment experience for guests. At events such as concerts, festivals, weddings, and parties, neon strip lights are used for decoration, transforming the venue into a magical and memorable space. They can be used to create backdrops, light up dance floors, and add a festive touch to the event setup.

Installation and Maintenance of Neon Strip Lights

Installation Procedures

The installation process for neon strip lights varies depending on the type of lights and the application. For traditional glass - tube neon strip lights, professional installation is often recommended due to the complexity of handling high - voltage systems and the fragility of the glass tubes. The installation typically involves mounting the tubes on a suitable frame, connecting the electrodes to the power supply, and ensuring proper insulation and grounding.

LED - based neon strip lights, on the other hand, are generally easier to install. Many LED neon strips come with adhesive backing, allowing them to be easily attached to clean, flat surfaces. They can also be cut to the desired length at designated intervals, and connectors are available for joining multiple strips together. When installing LED neon strip lights, it's important to follow the manufacturer's instructions regarding power supply requirements and wiring to ensure safe and proper operation.

Maintenance Requirements

Traditional glass - tube neon strip lights require regular maintenance to ensure optimal performance. The glass tubes should be inspected regularly for any signs of damage, such as cracks or leaks. If a tube is damaged, it may need to be replaced. The electrodes also need to be checked for wear and tear, and any loose connections should be tightened. The high - voltage power supply should be inspected periodically to ensure it is functioning correctly.

LED - based neon strip lights are relatively low - maintenance. LEDs have a long lifespan, and as long as they are not physically damaged, they are likely to continue working for an extended period. However, it's still advisable to periodically check the connections and the power supply to ensure everything is in working order. Cleaning the strips with a soft, dry cloth to remove dust and debris can also help maintain their performance and appearance.

Emerging Trends and Future Prospects of Neon Strip Lights

Smart and Connected Neon Strip Lights

One of the most significant trends in neon strip lights is the integration of smart technology. Smart neon strip lights can be controlled using a smartphone app, a voice - activated assistant, or a home automation system. This allows users to adjust the color, brightness, and lighting effects of the strips remotely, providing greater convenience and customization. Smart lighting systems also enable features such as scheduling, where the strips can be set to turn on and off at specific times, or reacting to certain events, like turning on when motion is detected. This integration with smart technology is likely to become more widespread, enhancing the functionality and user experience of neon strip lights.

Energy - Efficiency and Sustainability Improvements

With the increasing focus on environmental protection and energy conservation, there is a growing demand for more energy - efficient and sustainable neon strip lights. LED - based neon strips, which are already more energy - efficient than traditional glass - tube neon, are expected to see further advancements in energy - saving technology. Manufacturers are researching and developing new materials and manufacturing processes to reduce the power consumption of neon strip lights while maintaining or improving their performance. Additionally, there is a trend towards using more sustainable materials in the production of neon strip lights, such as recycled materials and eco - friendly coatings, to minimize the environmental impact.

Customization and Personalization

Consumers today are increasingly seeking personalized products, and neon strip lights are no exception. Manufacturers are offering more options for customization, allowing customers to choose from a wider range of colors, shapes, and lighting effects. Some companies even provide custom - design services, where customers can create their own unique neon strip light designs to suit their specific needs and preferences. This trend towards customization is likely to continue, as it allows users to express their individuality and create lighting solutions that are truly one - of - a - kind.

In conclusion, neon strip lights have come a long way since their inception and continue to play a vital role in the lighting industry. With their unique combination of functionality, aesthetic appeal, and technological innovation, they offer endless possibilities for various applications. As technology continues to evolve, we can expect to see even more exciting developments in the world of neon strip lights, further expanding their potential and influence in the future.