Time:2025-06-25

Neon strip lights have become an iconic and versatile element in the realm of modern lighting, captivating audiences with their vibrant glow and adaptability across diverse settings. From the bustling streets adorned with dazzling commercial signs to the intimate corners of residential spaces seeking a touch of ambiance, these lights have transcended their initial utilitarian purpose to become a powerful medium for creative expression. This article embarks on a detailed journey through the world of neon strip lights, delving into their technological evolution, functional characteristics, varied applications, and the considerations essential for optimal utilization.

The Evolution of Neon Strip Lights Technology

The Origins of Neon Lighting

The story of neon strip lights traces back to the early 20th century, a period marked by significant advancements in electrical engineering. In 1910, French engineer Georges Claude introduced the first commercial neon lamp, a revolutionary development that harnessed the properties of neon gas. When an electric current was passed through a sealed glass tube filled with neon, the gas became ionized, emitting a distinctive red - orange glow. This discovery laid the foundation for the neon lighting industry, with the first neon signs quickly emerging as a popular means of attracting attention in urban environments. The unique visual appeal of neon, combined with its ability to be shaped into various forms, made it an instant hit among advertisers and designers.

The Rise of LED - Based Neon Strips

While traditional neon lighting maintained its popularity for decades, the advent of Light - Emitting Diode (LED) technology in the latter half of the 20th century sparked a new era for neon strip lights. LEDs, semiconductor devices that convert electrical energy into light, offered several distinct advantages over their gas - filled counterparts. LED - based neon strips were more energy - efficient, consuming significantly less power while producing comparable or even brighter illumination. They also boasted a longer lifespan, were more resistant to physical damage, and could be easily controlled to produce a wide range of colors and lighting effects. This technological shift not only made neon strip lights more accessible and cost - effective but also expanded their potential applications far beyond traditional signage.

Modern Technological Innovations

In recent years, continuous research and development have led to further refinements in neon strip light technology. Advanced manufacturing techniques have enabled the production of more flexible and durable strips, capable of conforming to complex shapes and surfaces. Smart technology integration has also become a prominent feature, allowing users to control neon strip lights remotely through smartphone apps or voice - activated assistants. These innovations have not only enhanced the functionality of neon strip lights but also opened up new possibilities for creative lighting design, enabling users to customize their lighting experiences with unprecedented precision.

Technological Foundations of Neon Strip Lights

Traditional Neon Lighting Principles

Traditional neon strip lights operate on the principle of gas discharge. Inside a sealed glass tube, a low - pressure noble gas, typically neon, argon, or a mixture of gases, is present. When a high - voltage electrical current is applied between the electrodes at the ends of the tube, the gas atoms become ionized. As the electrons in the ionized gas return to their ground state, they release energy in the form of photons, producing light. The color of the light depends on the type of gas used: pure neon emits a red light, while argon produces a blue - violet glow. Phosphor coatings can also be applied to the inside of the tube to create additional colors, expanding the visual palette of traditional neon lighting.

LED Technology in Neon Strips

LED - based neon strips, on the other hand, rely on the unique properties of semiconductors. When an electric current passes through an LED, electrons recombine with electron holes in the semiconductor material, releasing energy in the form of light. The color of the light emitted by an LED is determined by the composition of the semiconductor material. By carefully selecting and arranging different types of LEDs, manufacturers can create neon strips that produce a wide range of colors, from vivid primaries to subtle pastels. Additionally, LED neon strips can be easily dimmed and controlled to create dynamic lighting effects, such as color - changing sequences and flashing patterns.

Circuitry and Control Systems

Both traditional and LED - based neon strip lights require sophisticated circuitry and control systems to function effectively. In traditional neon lighting, high - voltage transformers are used to step up the electrical voltage to the levels required for gas ionization. Control systems may include devices for adjusting the intensity of the light, creating flashing or chasing effects, or synchronizing multiple neon signs. LED neon strips, meanwhile, utilize electronic drivers to regulate the electrical current flowing to the LEDs, ensuring consistent brightness and color output. Modern LED control systems often incorporate microcontrollers and wireless communication technologies, enabling users to control the lights remotely and create complex lighting scenes.

Manufacturing Processes of Neon Strip Lights

Traditional Neon Strip Light Production

The manufacturing of traditional neon strip lights is a meticulous and labor - intensive process. It begins with the selection of high - quality glass tubes, which are carefully cleaned and inspected for any defects. The tubes are then bent into the desired shapes using specialized equipment, a process that requires great skill and precision to ensure the integrity of the tube and the proper functioning of the gas - discharge process. Once bent, electrodes are sealed into the ends of the tube, and the tube is evacuated to remove air and other impurities. The appropriate gas or gas mixture is then introduced into the tube under low pressure, and the tube is sealed again to prevent gas leakage. Finally, the neon strip is tested for electrical and optical performance before being packaged for distribution.

LED Neon Strip Light Manufacturing

The production of LED neon strip lights involves a different set of processes. It starts with the fabrication of the printed circuit board (PCB), which serves as the foundation for the strip. High - quality LEDs are then mounted onto the PCB using surface - mount technology (SMT), a precise and automated process that ensures accurate placement and soldering of the components. Once the LEDs are mounted, the PCB is encapsulated in a protective material, typically silicone or plastic. This encapsulation not only protects the internal components from physical damage, moisture, and dust but also helps to diffuse the light evenly, creating a smooth and consistent glow. After encapsulation, the LED neon strips undergo rigorous testing to ensure their quality and performance, including tests for electrical conductivity, color accuracy, and durability.

Quality Control and Assurance

Regardless of the type, quality control is an essential aspect of neon strip light manufacturing. Manufacturers employ a variety of testing methods to ensure that their products meet strict quality standards. These tests may include visual inspections, electrical tests, and performance evaluations under different environmental conditions. In addition, many manufacturers adhere to international quality management systems, such as ISO 9001, to ensure consistent product quality and customer satisfaction. By implementing rigorous quality control measures, manufacturers can minimize the risk of defects and ensure that their neon strip lights provide reliable and long - lasting performance.

Key Features and Advantages of Neon Strip Lights

Flexibility and Customizability

One of the most significant advantages of neon strip lights is their flexibility. Traditional neon lights can be bent into various shapes, allowing for the creation of custom - designed signs and decorative elements. LED neon strips, however, offer even greater flexibility, as they are often encased in a flexible silicone or plastic material. This flexibility enables the strips to be easily curved, twisted, and shaped to fit a wide range of surfaces and design requirements, making them ideal for both simple and complex lighting installations. Additionally, neon strip lights can be customized in terms of color, length, and lighting effects, allowing users to create unique and personalized lighting solutions that meet their specific needs.

Aesthetic Appeal

Neon strip lights are renowned for their striking aesthetic appeal. The bright, vibrant glow of neon lights can add a touch of glamour and excitement to any space, making them a popular choice for both commercial and residential applications. Whether used to create a bold statement in a storefront window or to add a subtle accent to a living room, neon strip lights have the ability to transform the look and feel of a space. The wide range of colors and lighting effects available also allows for endless creative possibilities, enabling designers to create lighting schemes that complement the overall style and ambiance of the environment.

Energy Efficiency (LED - based)

LED - based neon strip lights offer significant energy - efficiency advantages over traditional neon lighting. LEDs consume less power while producing the same amount of light, resulting in lower electricity bills and reduced environmental impact. Additionally, the long lifespan of LEDs means that LED neon strips require less frequent replacement, further reducing energy consumption associated with manufacturing and disposal. As energy costs continue to rise and environmental concerns become more pressing, the energy - efficient nature of LED neon strip lights makes them an increasingly attractive option for both commercial and residential users.

Durability and Longevity

Neon strip lights are designed to be durable and long - lasting. Traditional neon lights, when properly installed and maintained, can last for many years. The glass tubes are made to withstand normal environmental conditions, and the gas - discharge process is relatively stable. LED neon strips, with their solid - state design and protective encapsulation, are even more resistant to physical damage, moisture, and other environmental factors. The long lifespan of both traditional and LED neon strip lights makes them a reliable and cost - effective lighting solution, reducing the need for frequent replacements and maintenance.

Diverse Applications of Neon Strip Lights

Commercial and Retail Signage

One of the most common applications of neon strip lights is in commercial and retail signage. The bright, eye - catching glow of neon lights makes them highly effective for attracting customers and promoting businesses. Neon signs can be used to display store names, logos, promotional messages, and directional information, making them an essential marketing tool for retailers, restaurants, and other commercial establishments. The ability to customize neon signs in terms of shape, color, and lighting effects allows businesses to create unique and memorable signage that stands out from the competition.

Interior Design and Decor

In interior design, neon strip lights are used to add a touch of style and personality to any space. They can be used to create ambient lighting, highlight architectural features, or add decorative accents. In living rooms, neon strips can be installed behind sofas, along ceiling coves, or under shelves to create a warm and inviting atmosphere. In bedrooms, they can be used to add a soft, romantic glow, while in kitchens, they can provide functional task lighting. The flexibility and customizability of neon strip lights make them a versatile choice for interior designers, enabling them to create unique and personalized lighting schemes that enhance the overall aesthetic of the space.

Event and Entertainment Venues

Neon strip lights are also widely used in event and entertainment venues to create a dynamic and engaging atmosphere. At concerts, festivals, and other live events, neon lights can be used to illuminate stages, create visual effects, and enhance the overall experience for attendees. In nightclubs and bars, neon strip lights are used to set the mood, with colorful and flashing lights adding to the energy and excitement of the space. The ability to control the color, intensity, and lighting effects of neon strip lights makes them an ideal choice for event planners and entertainment venue operators, allowing them to create unique and memorable experiences for their guests.

Architectural Lighting

Architects often incorporate neon strip lights into their designs to enhance the visual appeal of buildings. Neon lights can be used to accentuate the unique features of a building's facade, such as edges, corners, and architectural details. By illuminating these elements, architects can create a dramatic and eye - catching effect, especially at night. Neon strip lights can also be used for interior architectural lighting, highlighting columns, arches, and other structural elements to add depth and dimension to the space. The flexibility and customizability of neon strip lights allow architects to create lighting designs that complement the overall architectural style and enhance the functionality of the building.

Considerations When Choosing Neon Strip Lights

Type of Neon Strip Light (Traditional vs. LED - based)

When choosing neon strip lights, one of the first decisions to make is whether to opt for traditional neon lights or LED - based neon strips. Traditional neon lights offer a classic and unique look, with a warm and soft glow that is difficult to replicate. However, they are more expensive to install and maintain, consume more energy, and are less flexible than LED neon strips. LED neon strips, on the other hand, are more energy - efficient, cost - effective, and flexible, offering a wider range of colors and lighting effects. Consider the specific requirements of your project, such as budget, energy efficiency, and design flexibility, when choosing between these two options.

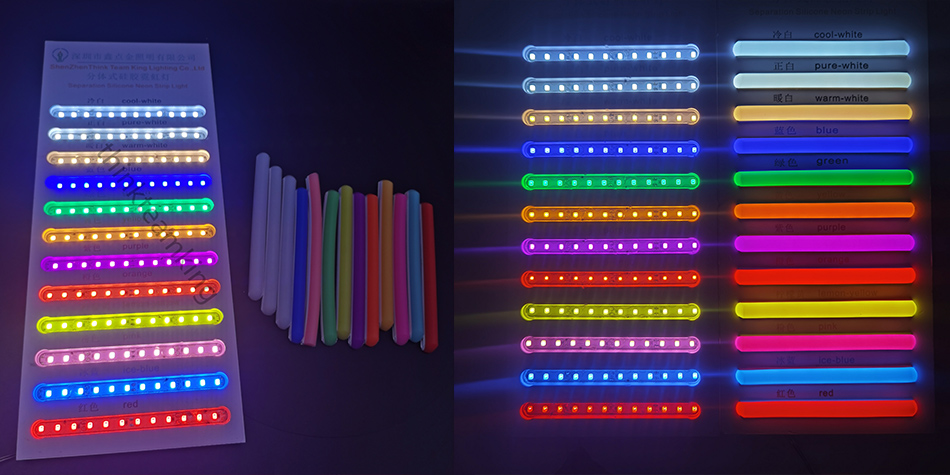

Color and Lighting Effects

The color and lighting effects of neon strip lights are crucial considerations. Think about the mood and atmosphere you want to create in the space, and choose colors and lighting effects that complement the overall design. For a relaxing and calming environment, soft and warm colors may be suitable, while bright and bold colors can add energy and excitement. Consider also the color - changing capabilities of the neon strip lights, as well as the ability to control the intensity and speed of the lighting effects. These features can add a dynamic and interactive element to your lighting design, allowing you to create different moods and atmospheres as needed.

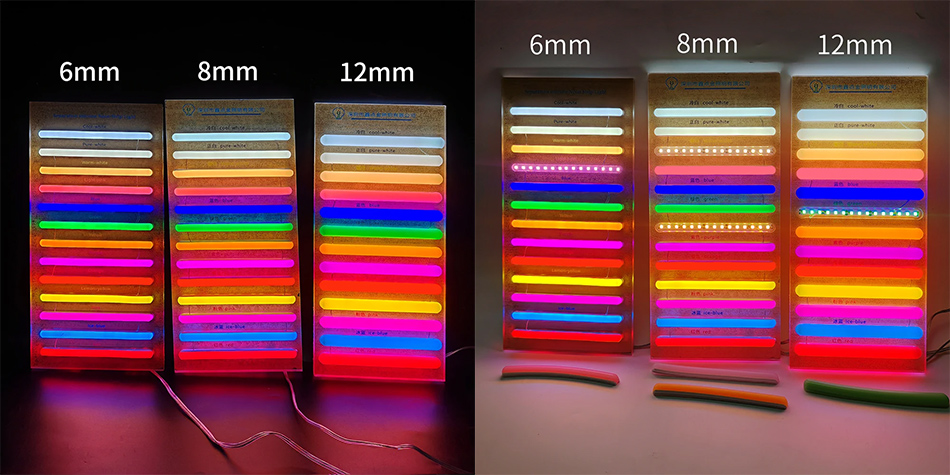

Length and Flexibility

The length and flexibility of the neon strip lights are important factors, especially if you need to fit them into specific spaces or create custom - shaped lighting installations. Measure the area where the lights will be installed accurately to ensure you choose the right length of the strip. Consider also the flexibility of the strip, as some applications may require the strip to be bent or curved in tight spaces. LED neon strips are generally more flexible than traditional neon lights, making them a better choice for complex installations.

Power Requirements and Energy Consumption

Understanding the power requirements and energy consumption of neon strip lights is essential, especially for large - scale installations or when aiming to reduce electricity costs. LED neon strips are more energy - efficient than traditional neon lights, but different models may still have varying power consumption levels. Check the product specifications for information on power input, voltage requirements, and estimated energy usage. Consider also the use of energy - saving features, such as dimming controls and motion sensors, to further reduce energy consumption.

Quality and Durability

Investing in high - quality neon strip lights is important to ensure long - term performance and reliability. Look for products from reputable manufacturers that use high - quality materials and have a proven track record of producing durable lighting products. Read customer reviews and testimonials to get an idea of the product's quality and performance. For outdoor applications, choose neon strip lights that are specifically designed to be weather - resistant and durable, with features such as waterproof encapsulation and UV protection.

Installation and Maintenance of Neon Strip Lights

Installation Process

The installation process for neon strip lights varies depending on the type of lights and the application. Traditional neon lights require professional installation due to the high - voltage electrical components and the need for specialized equipment for bending and sealing the glass tubes. LED neon strips, on the other hand, are generally easier to install, with many models featuring adhesive backing for simple surface mounting. However, proper electrical connections still need to be made, and it's important to follow the manufacturer's instructions carefully to ensure safe and proper installation. For more complex installations, such as those involving multiple strips or custom - shaped designs, it may be advisable to seek the assistance of a professional electrician.

Maintenance Requirements

Maintenance of neon strip lights also depends on the type of lights. Traditional neon lights may require occasional cleaning of the glass tubes to remove dust and dirt, which can affect the light output. They may also need periodic inspection for gas leaks or electrical issues. LED neon strips are generally low - maintenance, but it's still a good idea to periodically check for any signs of damage, such as cracks in the silicone encapsulation or loose connections. If an LED fails, in most cases, the entire strip may need to be replaced, depending on the design. Regular maintenance will help ensure the longevity and optimal performance of the neon strip lights, keeping them looking and functioning their best for years to come.