Time:2025-06-21

In the dynamic and competitive landscape of the lighting industry, certified silicone neon light strip OEM (Original Equipment Manufacturer) manufacturers play a pivotal role. These manufacturers are at the forefront of producing high - quality, innovative, and reliable lighting solutions that meet the diverse needs of various markets. This article delves into the world of certified silicone neon light strip OEM manufacturers, exploring their significance, the certification process, manufacturing capabilities, and how they contribute to the growth and success of businesses in the lighting sector.

The Significance of Certified Silicone Neon Light Strip OEM Manufacturers

Quality Assurance

Certified OEM manufacturers are committed to maintaining the highest standards of quality. The certification process, which often involves rigorous testing and evaluation against international standards, ensures that the silicone neon light strips produced are of top - notch quality. This quality assurance is crucial for both the end - users and the businesses that partner with these OEMs. For end - users, it means they can rely on the longevity, performance, and safety of the light strips. For businesses, it provides a competitive edge in the market, as they can offer products that are known for their quality and reliability.

Customization and Innovation

One of the key advantages of working with certified silicone neon light strip OEM manufacturers is their ability to offer customization options. These manufacturers have the expertise and resources to develop light strips tailored to the specific requirements of their clients. Whether it's a unique color, a particular shape, or a specific functionality, OEMs can bring innovative ideas to life. Their research and development capabilities enable them to stay ahead of the curve, incorporating the latest technologies and design trends into their products. This innovation not only meets the current market demands but also helps to shape future trends in the lighting industry.

Cost - Efficiency

OEM manufacturers operate on a large - scale production model, which allows them to achieve economies of scale. This, in turn, results in cost - efficiency for their clients. By producing in bulk, they can source raw materials at lower prices and streamline their production processes. Businesses that partner with these OEMs can benefit from competitive pricing without compromising on the quality of the silicone neon light strips. This cost - effectiveness is especially important in price - sensitive markets, where affordability can be a decisive factor in the success of a product.

The Certification Process for Silicone Neon Light Strip Manufacturers

International Standards Compliance

Certification for silicone neon light strip manufacturers typically involves compliance with international standards such as UL (Underwriters Laboratories), CE (Conformité Européene), and RoHS (Restriction of Hazardous Substances). UL certification, for example, focuses on product safety, ensuring that the light strips meet strict safety criteria, including electrical safety, fire resistance, and mechanical integrity. CE certification indicates that the product complies with European health, safety, and environmental protection regulations. RoHS certification ensures that the product does not contain hazardous substances such as lead, mercury, and cadmium, making it environmentally friendly.

Testing and Evaluation

To obtain these certifications, manufacturers must undergo a series of comprehensive tests and evaluations. These tests may include electrical performance testing, where the light strips are subjected to various electrical conditions to ensure stable and efficient operation. Environmental testing is also crucial, which assesses the product's performance in different environmental conditions, such as temperature variations, humidity, and exposure to UV light. Mechanical testing evaluates the durability of the light strips, including their resistance to bending, impact, and vibration. Only after successfully passing these tests can a manufacturer be awarded the relevant certifications.

Quality Management Systems

In addition to product - specific testing, certification bodies also evaluate the manufacturer's quality management systems. This includes assessing the company's processes for raw material procurement, production control, quality inspection, and product traceability. A well - established quality management system ensures that the manufacturing process is consistent and that all products meet the required standards. Manufacturers are required to document their processes and procedures, and these are regularly audited by certification bodies to maintain the validity of the certifications.

Manufacturing Capabilities of Certified OEMs

Advanced Production Facilities

Certified silicone neon light strip OEM manufacturers are equipped with state - of - the - art production facilities. These facilities are designed to handle high - volume production while maintaining strict quality control. Automated production lines are commonly used to ensure precision and efficiency in the manufacturing process. For example, advanced soldering machines are used to attach the LED chips to the circuit boards, ensuring a reliable electrical connection. High - speed extrusion machines are employed to create the silicone casing, which provides protection and a uniform light diffusion effect.

Skilled Workforce

Behind the advanced production facilities is a team of skilled and experienced workers. These professionals are well - trained in all aspects of silicone neon light strip manufacturing, from the initial design and prototyping to the final production and quality inspection. They have in - depth knowledge of the materials used, such as different types of silicone, LED chips, and circuit board materials. Their expertise allows them to troubleshoot any issues that may arise during the production process and make necessary adjustments to ensure the production of high - quality light strips.

Quality Control and Inspection

Quality control is a top priority for certified OEMs. Multiple quality inspection points are integrated into the production process. Raw materials are inspected upon arrival to ensure they meet the required specifications. During production, in - line inspections are carried out to monitor the quality of the semi - finished products. Final inspections are conducted on the completed light strips to check for any defects in appearance, functionality, and performance. Only products that pass all these inspections are released for shipment, ensuring that only the highest - quality silicone neon light strips reach the market.

Customization Services Offered by OEM Manufacturers

Design Customization

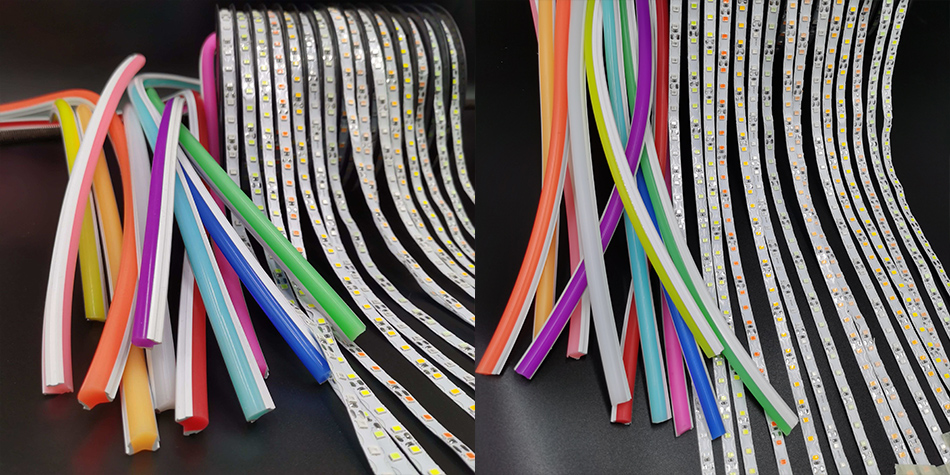

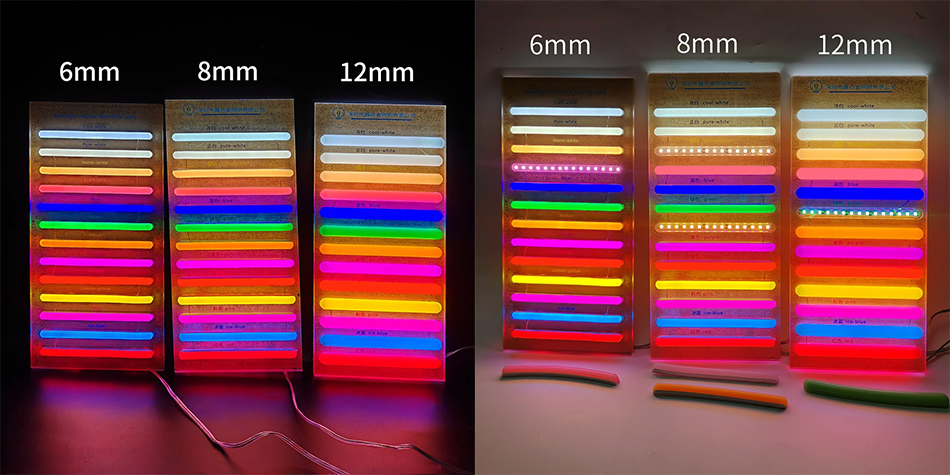

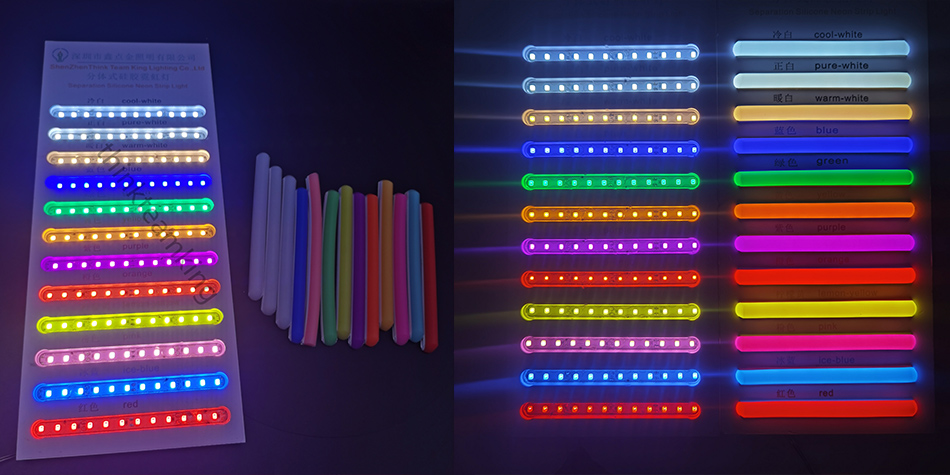

OEM manufacturers work closely with their clients to develop customized designs for silicone neon light strips. This may involve creating unique shapes and sizes to fit specific applications. For example, in architectural lighting, light strips may need to be bent or shaped to follow the contours of a building's facade or interior features. OEMs can design and produce light strips with the flexibility to be easily installed in such complex geometries. They can also customize the color options, offering a wide range of standard colors as well as the ability to match specific color codes provided by the client.

Functionality Customization

In addition to design, OEMs can customize the functionality of the silicone neon light strips. This may include integrating different types of control systems, such as dimming capabilities, color - changing features, or synchronization with other lighting or electronic devices. For example, for a smart home application, the light strips can be designed to be controlled via a mobile app or voice commands. OEMs can also incorporate special features like waterproofing for outdoor use or anti - glare coatings for applications where a softer, more diffused light is required.

Packaging Customization

The packaging of the silicone neon light strips is another area where OEMs offer customization. They can design packaging that not only protects the product during transportation and storage but also serves as a marketing tool. Custom - branded packaging with the client's logo, product information, and attractive graphics can help to enhance the brand image and make the product more appealing on the shelves. OEMs can also provide different packaging options, such as retail - ready packaging for direct sale to consumers or bulk packaging for businesses that distribute the products to other retailers.

How Certified OEMs Support Businesses in the Lighting Industry

Brand Building

For businesses in the lighting industry, partnering with a certified silicone neon light strip OEM can be a significant step in brand building. By offering high - quality, customized products, businesses can differentiate themselves in the market and build a reputation for reliability and innovation. The certifications held by the OEM add credibility to the products, instilling confidence in customers. The ability to offer unique and innovative lighting solutions also helps businesses to attract new customers and retain existing ones, contributing to long - term brand loyalty.

Market Expansion

The wide range of customization options provided by OEMs enables businesses to expand into new markets. For example, by developing specialized light strips for niche applications such as automotive interior lighting or museum display lighting, businesses can tap into previously untapped customer segments. The cost - efficiency offered by OEMs also allows businesses to price their products competitively in different markets, making it easier to penetrate new regions and gain market share.

Product Development and Innovation

Certified OEMs act as valuable partners in product development and innovation. Their in - house research and development teams can collaborate with businesses to develop new and improved silicone neon light strip products. They can provide insights into the latest industry trends, materials, and technologies, helping businesses to stay ahead of the competition. By working together, businesses and OEMs can bring innovative lighting solutions to the market more quickly, meeting the evolving needs of customers.

Challenges and Solutions in the OEM Manufacturing of Silicone Neon Light Strips

Raw Material Sourcing

One of the challenges faced by OEM manufacturers is ensuring a stable supply of high - quality raw materials. Fluctuations in the availability and price of materials such as silicone, LED chips, and circuit board components can impact production schedules and costs. To address this, OEMs often establish long - term partnerships with reliable suppliers. They also conduct regular market research to stay informed about potential material shortages or price changes. Some OEMs may even invest in alternative material sources or develop in - house capabilities to produce certain components, reducing their dependence on external suppliers.

Technological Advancements

The lighting industry is constantly evolving, with new technologies emerging regularly. OEM manufacturers need to keep up with these technological advancements to remain competitive. This requires significant investment in research and development and continuous training for their workforce. To overcome this challenge, OEMs often collaborate with research institutions and technology companies. They also participate in industry conferences and exhibitions to stay updated on the latest trends and technologies. By fostering a culture of innovation within the company, OEMs can quickly adapt to new technological developments and incorporate them into their products.

Competition

The OEM manufacturing market for silicone neon light strips is highly competitive, with many manufacturers vying for the same customers. To stand out in this crowded market, OEMs need to differentiate themselves in terms of quality, price, and innovation. They must continuously improve their production processes to reduce costs while maintaining high - quality standards. OEMs also need to focus on building strong relationships with their clients, providing excellent customer service and support. By offering unique value propositions, such as advanced customization options or faster production lead times, OEMs can gain a competitive edge in the market.

Future Trends and Outlook for Certified Silicone Neon Light Strip OEM Manufacturers

Smart Lighting Integration

The future of silicone neon light strips lies in smart lighting integration. OEM manufacturers are likely to see an increasing demand for light strips that can be integrated into smart home and building automation systems. This will require them to develop products with enhanced connectivity features, such as Wi - Fi or Bluetooth compatibility, and the ability to be controlled remotely. OEMs may also need to work on integrating sensors into the light strips, allowing for functions like motion - activated lighting or automatic dimming based on ambient light levels.

Sustainable Manufacturing

As environmental concerns continue to grow, there will be a greater emphasis on sustainable manufacturing in the lighting industry. OEMs will need to focus on using eco - friendly materials and production processes. This may involve using recycled or biodegradable silicone, reducing energy consumption during production, and minimizing waste. Certifications related to sustainability, such as ISO 14001 for environmental management systems, may become more important for OEMs to demonstrate their commitment to environmental responsibility.

Expansion into New Markets

With the increasing popularity of silicone neon light strips in various applications, OEM manufacturers are expected to expand into new markets. This could include emerging economies where there is a growing demand for modern lighting solutions. OEMs may also explore new application areas, such as healthcare facilities, where specialized lighting is required for patient comfort and well - being. By leveraging their manufacturing capabilities and customization services, OEMs can tap into these new markets and drive further growth in the industry.

In conclusion, certified silicone neon light strip OEM manufacturers are integral to the success of the lighting industry. Their commitment to quality, innovation, and customization, along with their ability to adapt to market trends and overcome challenges, positions them well for future growth. As the industry continues to evolve, these OEMs will play a crucial role in shaping the future of lighting with their advanced products and manufacturing capabilities.