Time:2025-12-22

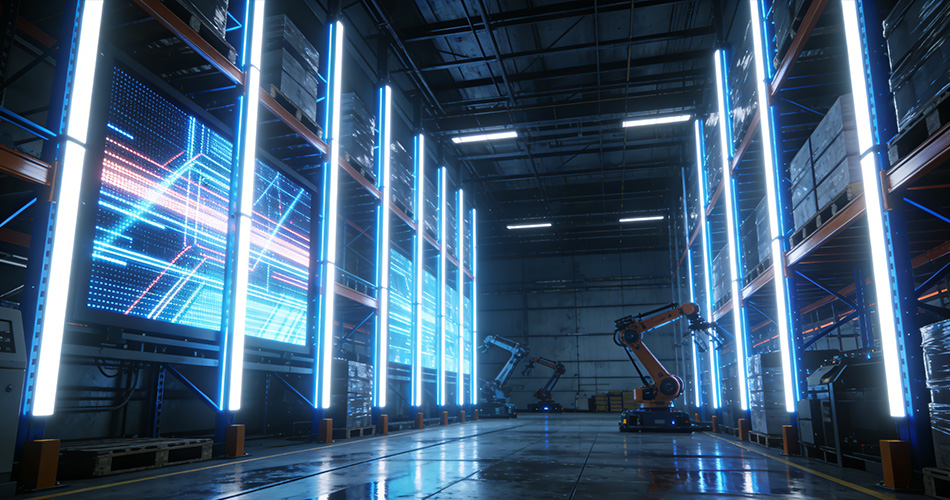

High-brightness neon warehouse lighting has emerged as a critical solution for modern warehousing operations, delivering the intense, uniform illumination required to optimize workflow efficiency while ensuring workplace safety in large, often harsh industrial environments. Unlike standard warehouse lighting options that may struggle with uneven brightness or insufficient coverage, high-brightness neon warehouse lighting combines the iconic neon glow with enhanced luminous intensity, enabling it to penetrate large warehouse spaces—from high-ceiling storage facilities to expansive sorting areas. Engineered for industrial use, these lighting solutions boast robust construction to withstand dust, vibration, and temperature fluctuations, making them ideal for e-commerce fulfillment centers, manufacturing warehouses, cold storage facilities, and logistics hubs. As warehouses increasingly prioritize operational efficiency and employee safety, high-brightness neon warehouse lighting stands out by reducing error rates in order picking, improving navigation, and complying with industrial safety standards, becoming an indispensable asset for industrial operations.

High-brightness neon warehouse lighting distinguishes itself from traditional warehouse lighting (such as fluorescent tubes or standard LED lights) by addressing the unique challenges of large-scale warehousing environments. Its core advantages are tailored to support industrial operational goals, including efficiency, safety, and long-term cost control:

1. Uniform High Brightness for Large Space Coverage – The defining feature of high-brightness neon warehouse lighting is its ability to emit intense, consistent light that covers wide warehouse areas without dark spots or glare. This uniform illumination is critical for tasks such as order picking, inventory counting, and machinery operation, where poor visibility can lead to errors, delays, or accidents. Unlike point-source lighting that creates uneven light distribution, high-brightness neon warehouse lighting provides linear, expansive coverage, ensuring every corner of the warehouse—from floor-level storage racks to high-ceiling shelving—remains clearly visible.

2. Industrial-Grade Durability for Harsh Environments – Designed specifically for warehouse conditions, high-brightness neon warehouse lighting features rugged, dust-tight, and moisture-resistant construction. The lighting fixtures are encased in durable materials that protect internal components from warehouse dust, debris, and minor impacts—common in busy logistics operations. They also withstand extreme temperature variations, making them suitable for cold storage facilities (where temperatures drop below freezing) and heated manufacturing warehouses. This durability minimizes downtime due to lighting failures, ensuring continuous operation of 24/7 warehouse facilities.

3. Safety Compliance & Workplace Protection – High-brightness neon warehouse lighting meets strict industrial safety standards for illumination levels, reducing the risk of workplace accidents such as trips, falls, or machinery collisions. The uniform, glare-free light improves visibility of safety signage, emergency exits, and potential hazards (such as protruding equipment or wet floors). Additionally, these lighting solutions operate on low voltage, emitting minimal heat and reducing fire risks—critical for warehouses storing flammable materials or operating heavy machinery. Compliance with industrial safety certifications ensures warehouses meet regulatory requirements and avoid penalties.

4. Energy Efficiency & Long-Term Cost Savings – Despite their high brightness, modern high-brightness neon warehouse lighting leverages energy-efficient LED neon technology, consuming significantly less power than traditional high-intensity discharge (HID) lights or fluorescent tubes. This energy efficiency translates to lower electricity bills for warehouses with extended operational hours. Additionally, these lighting solutions have a long service life (up to 50,000 hours), reducing the frequency of replacements and maintenance costs—key for large warehouses where lighting maintenance is labor-intensive and costly.

Leveraging its high-brightness output, industrial durability, and safety features, high-brightness neon warehouse lighting is widely applicable across various types of warehouse and logistics facilities, each time addressing sector-specific illumination needs:

E-commerce fulfillment centers rely on high-brightness neon warehouse lighting to support fast-paced order picking and packing operations. The uniform high brightness ensures that warehouse staff can quickly identify product labels, scan barcodes, and navigate between densely packed storage racks with minimal errors. These lighting solutions are often installed along aisles, above picking stations, and around conveyor belts, providing consistent illumination that reduces eye strain during long shifts. For 24/7 fulfillment centers, the energy efficiency and long lifespan of high-brightness neon warehouse lighting further reduce operational costs.

Manufacturing warehouses and production facilities use high-brightness neon warehouse lighting to illuminate machinery operation areas, assembly lines, and raw material storage zones. The intense, glare-free light improves visibility of precision tasks (such as component assembly) and helps identify equipment malfunctions or safety hazards. The rugged construction of these lighting solutions withstands vibration from heavy machinery and protects against dust and oil splatters common in manufacturing environments. Additionally, their low heat emission prevents overheating in areas with high machinery density.

Cold storage facilities and refrigerated warehouses require lighting solutions that can perform reliably in sub-zero temperatures—a challenge for many standard lighting options. High-brightness neon warehouse lighting is engineered to withstand extreme cold, maintaining consistent brightness and performance even in temperatures as low as -20°C. This makes it ideal for illuminating frozen food storage areas, pharmaceutical cold rooms, and refrigerated logistics hubs. The low heat emission of these lights also helps maintain stable internal temperatures, reducing the load on cooling systems and saving energy.

Large logistics and distribution hubs, with their expansive floor plans and high ceilings, demand lighting solutions that can cover vast areas efficiently. High-brightness neon warehouse lighting is installed in overhead fixtures and along loading docks, providing uniform illumination that supports truck loading/unloading operations, inventory management, and vehicle navigation within the facility. The durable construction of these lights withstands the constant movement of forklifts and other material handling equipment, while their high brightness ensures visibility even in foggy or dusty conditions common in outdoor-connected loading areas.

To select the right high-brightness neon warehouse lighting for your facility, focus on criteria that align with industrial operational needs, environmental conditions, and safety requirements. The following key factors are critical for warehouse applications:

1. Brightness Uniformity & Coverage – Prioritize lighting solutions that offer consistent brightness across the entire coverage area, avoiding dark spots or glare. For high-ceiling warehouses, choose fixtures designed to direct light downward effectively, ensuring floor-level visibility. Consider the layout of your warehouse (aisle width, rack height) to select lighting that matches the space dimensions.

2. Industrial Durability & Environmental Rating – Select lighting with a high IP (Ingress Protection) rating (e.g., IP65 or higher) to resist dust and moisture. For cold storage facilities, choose models rated for low-temperature operation. Ensure the fixtures are constructed with robust materials that can withstand vibration, impact, and harsh industrial chemicals.

3. Safety Certifications & Compliance – Verify that the lighting meets international industrial safety standards, such as CE, UL, or OSHA certifications. Ensure the product complies with local regulations for warehouse illumination levels and electrical safety. For warehouses storing hazardous materials, select lighting with explosion-proof or flame-retardant features.

4. Energy Efficiency & Maintenance Requirements – Opt for energy-efficient LED neon models to reduce long-term electricity costs. Choose lighting with a long service life to minimize replacement frequency. Consider fixtures with easy-access designs for maintenance, as this reduces downtime and labor costs in large warehouses.

5. Installation & Compatibility – Select lighting that is compatible with your warehouse’s existing electrical system. For large-scale installations, choose fixtures with easy mounting options (such as ceiling brackets or suspension kits) to reduce installation time and labor costs. Consider whether the lighting can be integrated with motion sensors or timers to further save energy by activating only when areas are in use.

High-brightness neon warehouse lighting is more than just an illumination solution—it is a strategic asset that enhances operational efficiency, ensures workplace safety, and reduces long-term costs for industrial facilities. By combining uniform high brightness, industrial-grade durability, safety compliance, and energy efficiency, it addresses the unique challenges of warehouse environments, from large space coverage to harsh operating conditions. Whether for e-commerce fulfillment centers, manufacturing warehouses, cold storage facilities, or logistics hubs, high-brightness neon warehouse lighting delivers reliable, consistent illumination that supports critical warehouse operations. Investing in high-quality high-brightness neon warehouse lighting is a cost-effective decision that improves productivity, protects employees, and ensures compliance with industrial standards, making it an essential choice for modern warehouse operations.